Renesis OIL PRESSURE Discussion with Dealer Tech

#426

If oil pressure is not going above 72 psi, then the motor will never achieve the "10-psi per 1k RPM" rule of thumb. Of course, as it has been stated numerous times, it's the flow rate that we really want, so technically 20psi could be sufficient if the rest of the system was designed for it - but it wasn't, correct?

Paul, is it safe to say that we want higher pressure because we are seeing excessive bearing wear, and that "low" oil pressure may be the culprit?

#427

#428

If oil pressure is not going above 72 psi, then the motor will never achieve the "10-psi per 1k RPM" rule of thumb. Of course, as it has been stated numerous times, it's the flow rate that we really want, so technically 20psi could be sufficient if the rest of the system was designed for it - but it wasn't, correct?

Paul, is it safe to say that we want higher pressure because we are seeing excessive bearing wear, and that "low" oil pressure may be the culprit?

Paul, is it safe to say that we want higher pressure because we are seeing excessive bearing wear, and that "low" oil pressure may be the culprit?

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

#429

Very true --- but speaking generally since I cant increase the flow, at least I can increase the film strenght of my oil.

The ONLY ways to increase flow is with a larger volumne pump/system or to fully utilize the pumps capacity which would increase the force the oil is being pumped through the system---NOT the resistance to the pumping.

OD

The ONLY ways to increase flow is with a larger volumne pump/system or to fully utilize the pumps capacity which would increase the force the oil is being pumped through the system---NOT the resistance to the pumping.

OD

#430

I'm not against some increase although it is totally un-necessary for the average person.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

*I hug my 15w50 oil even when Im sleeping*

#431

#432

I'm not against some increase although it is totally un-necessary for the average person.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

Is the filter inadequate to clear out debris? Would a larger filter, perhaps for the RX-2 or something similar, be better?

Would an increase in pressure at higher rpm and load be beneficial at all, if only as a bandaid?

Last edited by longpath; 10-29-2009 at 09:21 AM.

#433

Paul.

#434

Have you a hypothesis as to what sort of remedy might be appropriate (0W-50?)?

Is the filter inadequate to clear out debris? Would a larger filter, perhaps for the RX-2 or something similar, be better?

Would an increase in pressure at higher rpm and load be beneficial at all, if only as a bandaid?

Is the filter inadequate to clear out debris? Would a larger filter, perhaps for the RX-2 or something similar, be better?

Would an increase in pressure at higher rpm and load be beneficial at all, if only as a bandaid?

The higher pressure should be sought by those who REALLY put the punishment to their 8 (Track time, turbos etc).

Paul.

#435

XW30 to XW50 would be my vote. The thicker film will keep the contaminants from doing their part of damage for the most part. We always liked to use some of the larger filters with the correct specifications when they can fit. I use the JEY0-14-302 on my 02 Protege5 and on my 05 RX8 when I had it. The recommended filter for both is the B6Y1-14-302.

The higher pressure should be sought by those who REALLY put the punishment to their 8 (Track time, turbos etc).

Paul.

The higher pressure should be sought by those who REALLY put the punishment to their 8 (Track time, turbos etc).

Paul.

can you tell how to easily achieve this to the stupid people? (yes, look at me

)

)

#437

I'm not against some increase although it is totally un-necessary for the average person.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

More flow should help with a thicker film in the bearings and removal of the debris faster though, so not a bad thing.

I wonder if part of the reason for so many problems is that the RX8 is much more of an everyday car than the -7 was, it's being used for short trips to the shops, running the kids to school, etc, whereas the -7 would generally be a weekend car or taken out for long runs by enthusiasts.

I'm tempted to use the S2 oil filter as that's quite a lot larger than the S1 as it is, are those part numbers you gave even bigger?

#438

The Angry Wheelchair

iTrader: (14)

Joined: May 2009

Posts: 1,865

Likes: 1

From: In da woodz, lurking after you

I'm not against some increase although it is totally un-necessary for the average person.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

One of the advantages of the higher pressure can be more cooling from the oil.

Paul.

If you meant it in regards to a thicker oil, how can a thicker oil result in more cooling? In theory and from what other research shows, thicker oil makes it more difficult to move the oil with the same pump and resistance thus the higher pressure and increases engine temperature. If it cooled the engine then I would think anyone in a hot environment or racing environment would be using thicker oil to "cool" the engine instead of running a lower weight which is not so. I'm pretty sure you're not referring to this definition, please clarify thanks

#440

#441

Pressure is not typically an issue with the rotary cars and it is not the issue with the bearing wear. We've seen it on a number of engines including those that do not see the highest rpms. It is simply a lubrication issue related to lack of protective barrier between the parts and the effects of contaminants (Debris in suspension) wearing away at the layers of bearing material in combination with normal loads. Too low of a viscosity is the culprit.

#442

thats the point i made earier.

during normal every day driving with heavier wgt oil at 4K there is a good chance that we are in the range of the rear bypass limit. Thereby not filtering all the oil.

get a magnet on the filter may help some as Ash pointed out and I also have done.

The mod on the rear bypass and front bypass is not hard to do if you have been working on cars some. Make SURE you keep things as clean as you possibily can. Drop the pan, remove the rear and front regulators/bypass, do the crush with a hydrolic press, or have a machine shop do it--or buy a new one (93-95) from MazdaTrix for $31, then add 2 shims --total 1/8 inch to the front bypass, then use the 09 filter(for its own increased bypass pressure) or something like a Fram hp2-6. Hell--even a Pure One Purolater has a filter that will fit and is twice as big as the oem although I am not sure of its bypass pressure.

Reinstall (careful with the pan bolts) CLEANLY and refill with a diesel oil or whatever you want to do and thats it.

Should take maybe 2 hrs?

OD

during normal every day driving with heavier wgt oil at 4K there is a good chance that we are in the range of the rear bypass limit. Thereby not filtering all the oil.

get a magnet on the filter may help some as Ash pointed out and I also have done.

The mod on the rear bypass and front bypass is not hard to do if you have been working on cars some. Make SURE you keep things as clean as you possibily can. Drop the pan, remove the rear and front regulators/bypass, do the crush with a hydrolic press, or have a machine shop do it--or buy a new one (93-95) from MazdaTrix for $31, then add 2 shims --total 1/8 inch to the front bypass, then use the 09 filter(for its own increased bypass pressure) or something like a Fram hp2-6. Hell--even a Pure One Purolater has a filter that will fit and is twice as big as the oem although I am not sure of its bypass pressure.

Reinstall (careful with the pan bolts) CLEANLY and refill with a diesel oil or whatever you want to do and thats it.

Should take maybe 2 hrs?

OD

#444

thats the point i made earier.

during normal every day driving with heavier wgt oil at 4K there is a good chance that we are in the range of the rear bypass limit. Thereby not filtering all the oil.

get a magnet on the filter may help some as Ash pointed out and I also have done.

The mod on the rear bypass and front bypass is not hard to do if you have been working on cars some. Make SURE you keep things as clean as you possibily can. Drop the pan, remove the rear and front regulators/bypass, do the crush with a hydrolic press, or have a machine shop do it--or buy a new one (93-95) from MazdaTrix for $31, then add 2 shims --total 1/8 inch to the front bypass, then use the 09 filter(for its own increased bypass pressure) or something like a Fram hp2-6. Hell--even a Pure One Purolater has a filter that will fit and is twice as big as the oem although I am not sure of its bypass pressure.

Reinstall (careful with the pan bolts) CLEANLY and refill with a diesel oil or whatever you want to do and thats it.

Should take maybe 2 hrs?

OD

during normal every day driving with heavier wgt oil at 4K there is a good chance that we are in the range of the rear bypass limit. Thereby not filtering all the oil.

get a magnet on the filter may help some as Ash pointed out and I also have done.

The mod on the rear bypass and front bypass is not hard to do if you have been working on cars some. Make SURE you keep things as clean as you possibily can. Drop the pan, remove the rear and front regulators/bypass, do the crush with a hydrolic press, or have a machine shop do it--or buy a new one (93-95) from MazdaTrix for $31, then add 2 shims --total 1/8 inch to the front bypass, then use the 09 filter(for its own increased bypass pressure) or something like a Fram hp2-6. Hell--even a Pure One Purolater has a filter that will fit and is twice as big as the oem although I am not sure of its bypass pressure.

Reinstall (careful with the pan bolts) CLEANLY and refill with a diesel oil or whatever you want to do and thats it.

Should take maybe 2 hrs?

OD

I'll probably do it during this summer's routine maintenance :p

Oil bypass over 4k rpm shouldn't be a big issue if we stay in some weight range. The problem is to determine which the right range is!

G

#445

True--cost benefit is always a thought!!!

remember that anytime you car has a oil pressure above 71psi--then you are not filtering all your oil.

this is proabaly much more important for me because I have put forced induction on my car.

By the way my motor mounts are working out nicely---wish i could send you a set!

What is the cost to ship to you I wonder?

OD

remember that anytime you car has a oil pressure above 71psi--then you are not filtering all your oil.

this is proabaly much more important for me because I have put forced induction on my car.

By the way my motor mounts are working out nicely---wish i could send you a set!

What is the cost to ship to you I wonder?

OD

#447

the s2 oil filter bypass is approx 22 psi or so, but that is not the bypass that is causing this. Its the rear. If the pressure is over 71-72 psi the rear bleeds off oil back to the oil pan to reduce the pressure. That oil is not filtered before it is picked up again by the pump.

OD

OD

#448

Some FACTS, not thought's...FACTS.....

And I happen to agree with Mazmart on Oil Viscosity....BUT...

As I have stated a 1000 times...the Oil Pumping system used in the S1 RX-8 is a 24 Year Old PLUS design...that is the Pump, and all the valves are designed for and from the NA FC and earlier rotaries which the recommended oil was a 'thick' 20W50.

The ONLY difference in the Oil Pumping System is that Mazda Changed the Front Oil Pump Pressure Valve "Spring" by part number, but NONE of us know why and in which way, stronger or weaker...higher or lower pressure.

So if pressure is not an issue, why the change?

BUT, even more 'interesting' Mazda did not alter the REAR VALVE at all, it is directly from the FC, in fact from a 13B RX-4,5 of 1975.

Which is normally a no no, change the front O Pump BY Pass Relief Pressure, you change the rear also?. Mazda have not done this.

I will say it again, I don't think the O Pressure is quite right and the Rec Viscosity Just Don't Cut it....I said this 3-4 years ago.

And in my time Bearing failure was NOT common at all...in fact it was very rare.

And I was selling $6000 a month of Rotary Parts when Rotor Housings were $140.00 each...

And I happen to agree with Mazmart on Oil Viscosity....BUT...

As I have stated a 1000 times...the Oil Pumping system used in the S1 RX-8 is a 24 Year Old PLUS design...that is the Pump, and all the valves are designed for and from the NA FC and earlier rotaries which the recommended oil was a 'thick' 20W50.

The ONLY difference in the Oil Pumping System is that Mazda Changed the Front Oil Pump Pressure Valve "Spring" by part number, but NONE of us know why and in which way, stronger or weaker...higher or lower pressure.

So if pressure is not an issue, why the change?

BUT, even more 'interesting' Mazda did not alter the REAR VALVE at all, it is directly from the FC, in fact from a 13B RX-4,5 of 1975.

Which is normally a no no, change the front O Pump BY Pass Relief Pressure, you change the rear also?. Mazda have not done this.

I will say it again, I don't think the O Pressure is quite right and the Rec Viscosity Just Don't Cut it....I said this 3-4 years ago.

And in my time Bearing failure was NOT common at all...in fact it was very rare.

And I was selling $6000 a month of Rotary Parts when Rotor Housings were $140.00 each...

#449

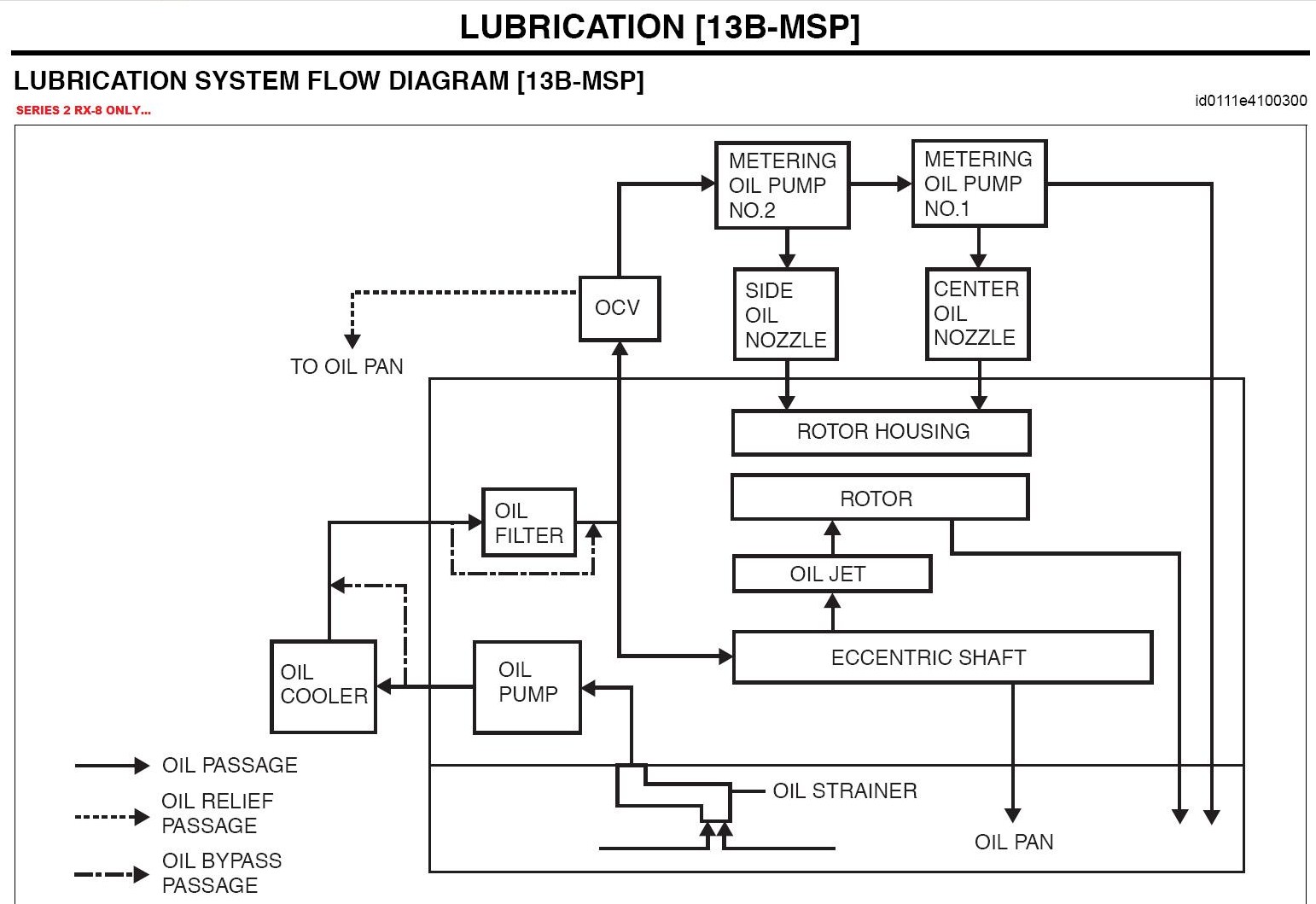

And the huge difference in Series II is that ALL the Oil is Filtered before it goes into the engine or EMOP's...

Again this is the first time Mazda Has done this...which is a good move.

Last edited by ASH8; 10-29-2009 at 12:56 PM.