an RX8er's rebuild thread

#1329

Registered

iTrader: (3)

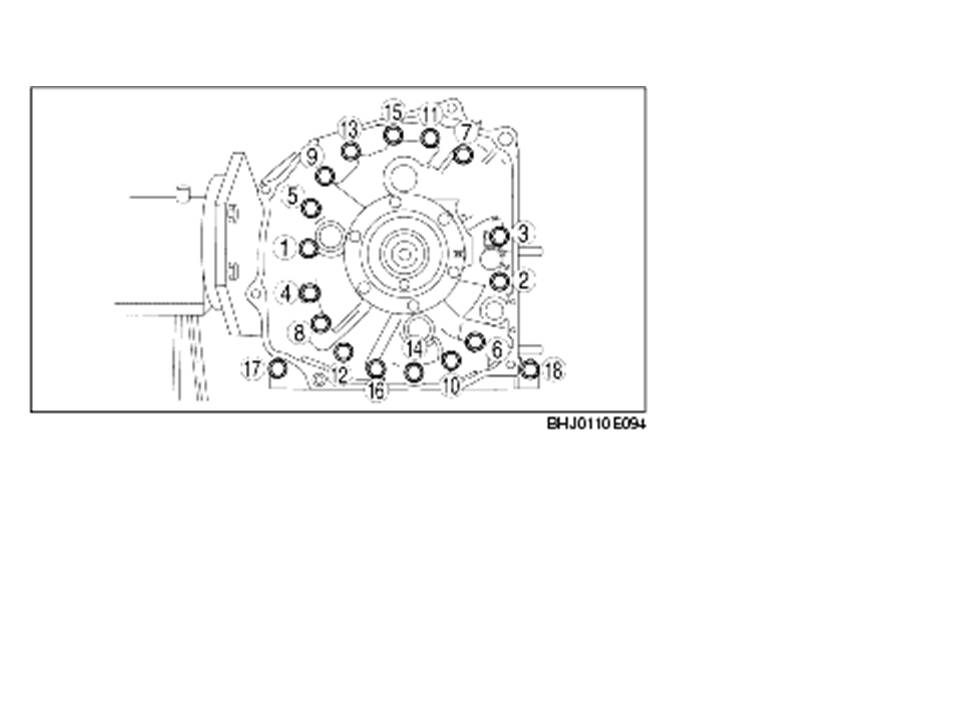

so basically outside to inside pattern. Hmmmm.

Now knowing that the actual tq on the engine bolts is not really that much, it does make me wonder what happens when all that tq is applied to the e shaft in attaching the front stuff and the flywheel etc. I know those high tq requirements doesnt directly affect the irons/housings, but if the e shaft is affected somehow then the rotor "floating" will be off some? Am I explaining myself ok?

Do yall know if anyone played with the engine bolt tq settings? I am just wondering.

The exhaust "pulses" are now directed to the sides of the engine and I also wonder if over time this possibly could be something that affects the housing irons line up. I have heard some builders say that it is wise to retorque the engine bolts if the flywheel is ever taken off.

IDK? What do yall think?

Now knowing that the actual tq on the engine bolts is not really that much, it does make me wonder what happens when all that tq is applied to the e shaft in attaching the front stuff and the flywheel etc. I know those high tq requirements doesnt directly affect the irons/housings, but if the e shaft is affected somehow then the rotor "floating" will be off some? Am I explaining myself ok?

Do yall know if anyone played with the engine bolt tq settings? I am just wondering.

The exhaust "pulses" are now directed to the sides of the engine and I also wonder if over time this possibly could be something that affects the housing irons line up. I have heard some builders say that it is wise to retorque the engine bolts if the flywheel is ever taken off.

IDK? What do yall think?

#1330

so basically outside to inside pattern. Hmmmm.

Now knowing that the actual tq on the engine bolts is not really that much, it does make me wonder what happens when all that tq is applied to the e shaft in attaching the front stuff and the flywheel etc. I know those high tq requirements doesnt directly affect the irons/housings, but if the e shaft is affected somehow then the rotor "floating" will be off some? Am I explaining myself ok?

Do yall know if anyone played with the engine bolt tq settings? I am just wondering.

The exhaust "pulses" are now directed to the sides of the engine and I also wonder if over time this possibly could be something that affects the housing irons line up. I have heard some builders say that it is wise to retorque the engine bolts if the flywheel is ever taken off.

IDK? What do yall think?

Now knowing that the actual tq on the engine bolts is not really that much, it does make me wonder what happens when all that tq is applied to the e shaft in attaching the front stuff and the flywheel etc. I know those high tq requirements doesnt directly affect the irons/housings, but if the e shaft is affected somehow then the rotor "floating" will be off some? Am I explaining myself ok?

Do yall know if anyone played with the engine bolt tq settings? I am just wondering.

The exhaust "pulses" are now directed to the sides of the engine and I also wonder if over time this possibly could be something that affects the housing irons line up. I have heard some builders say that it is wise to retorque the engine bolts if the flywheel is ever taken off.

IDK? What do yall think?

also the bolts are torqued with the flywheel off....not sure you could re-torque them after you install the FW.....also keep in mind I have all new hosings/irons

Last edited by houstonrx8er; 07-18-2012 at 09:33 AM.

#1331

WENTGERMAN

iTrader: (6)

I think that the wear is the exact same as before, meaning that something is off. Considering we removed and replaced all elements but the rotors, eshaft, cw, and stationary gears that means that something is inconsistent in the rotational assembly.

That's what I think...

I think she needs to get sent off to get balanced and I think that they will find the rotational assembly is out of balance.

That's what I think...

I think she needs to get sent off to get balanced and I think that they will find the rotational assembly is out of balance.

#1333

if you look at the bearing wear but I not convinced that is the issue and based on a comment from Charles he has taken apart many engines with similar bearing wear.

but like before I didn’t think it was compression either I wonder if it is just coincidental and the issue is caused by out of tolerance apex's or something of the sort

I wonder if it is just coincidental and the issue is caused by out of tolerance apex's or something of the sort

but like before I didn’t think it was compression either

I wonder if it is just coincidental and the issue is caused by out of tolerance apex's or something of the sort

I wonder if it is just coincidental and the issue is caused by out of tolerance apex's or something of the sort

#1334

WENTGERMAN

iTrader: (6)

Fair enough... but the same wear twice at the same location?

I mean... I guess its possible.

Generally when I troubleshoot things at work, at home, on the car etc. I remove the variables one by one until I have a solution.

I use this tactic on women as well, however I am still single so maybe it doesn't work. .

.

I mean... I guess its possible.

Generally when I troubleshoot things at work, at home, on the car etc. I remove the variables one by one until I have a solution.

I use this tactic on women as well, however I am still single so maybe it doesn't work.

.

.

#1335

Fair enough... but the same wear twice at the same location?

I mean... I guess its possible.

Generally when I troubleshoot things at work, at home, on the car etc. I remove the variables one by one until I have a solution.

I use this tactic on women as well, however I am still single so maybe it doesn't work. .

.

I mean... I guess its possible.

Generally when I troubleshoot things at work, at home, on the car etc. I remove the variables one by one until I have a solution.

I use this tactic on women as well, however I am still single so maybe it doesn't work.

.

.I think we are removing variables

with women keep in mind you cant remove anyhting (except w/surgery)....there inlies your first problem....now move on to why its your fault and they will fall at your feet

or

or

#1336

WENTGERMAN

iTrader: (6)

the wear is not in the same place....just similar. I will be pulling out my old irons to measure and I think I kept the old bearing just for the hell of it....worst case I have photos

I think we are removing variables

with women keep in mind you cant remove anyhting (except w/surgery)....there inlies your first problem....now move on to why its your fault and they will fall at your feet or

or

I think we are removing variables

with women keep in mind you cant remove anyhting (except w/surgery)....there inlies your first problem....now move on to why its your fault and they will fall at your feet

or

or

We can check it out this weekend!

#1339

right...I have a HB special....probably wont get the job done (I personally dont like air tools)

#1342

When building for one-piece apex seals I pore through several brand-new housings to find those which will perfectly fit with the apex seals, respective to the relationship between seal length and housing thickness/width. Since housing thickness can vary a bit from one to the next, see why these measurements are crucial and why the two-piece seal was devised?

I am BHR flywheel.....good point would a new clutch/pressure plate and FW need to be balanced with the assembly?

#1343

Registered

iTrader: (3)

its worth a thought?

found this info that was interesting to me

"torque specs are for clean dry bolts. The bolt needs to be stretched into it's working range. Like a spring, but not too far. Pull it too far and it isn't a spring anymore. It may become two pieces.

If you lubricate the threads and under the head and under the washer, and then use the dry thread torque figure, you have already over torqued the bolt.

In the case of case bolts (pun) they are so long that they have a big working range, and there is some latitude on torque that can be used. If you get to close to the top end of the working range, the engine will grow a bit with heat and over stretch a bolt. It may not break, but will not return to the correct tension during the next heat cycle. The over torqued bolt is now (undertorqued). Racing Beat has a list of overtorques to use for different end uses.

The bolts ring like bells, or more likely, guitar strings, in sympathy to the harmonics of engine RPM. The race bolts have a rubber sleeve molded onto the center of the bolt to prevent that. You can just slather on a spiral bead of silicone and do the same thing. The ringing bolt tends to break off right at the front iron in the threaded area."

end

something to think about....?

found this info that was interesting to me

"torque specs are for clean dry bolts. The bolt needs to be stretched into it's working range. Like a spring, but not too far. Pull it too far and it isn't a spring anymore. It may become two pieces.

If you lubricate the threads and under the head and under the washer, and then use the dry thread torque figure, you have already over torqued the bolt.

In the case of case bolts (pun) they are so long that they have a big working range, and there is some latitude on torque that can be used. If you get to close to the top end of the working range, the engine will grow a bit with heat and over stretch a bolt. It may not break, but will not return to the correct tension during the next heat cycle. The over torqued bolt is now (undertorqued). Racing Beat has a list of overtorques to use for different end uses.

The bolts ring like bells, or more likely, guitar strings, in sympathy to the harmonics of engine RPM. The race bolts have a rubber sleeve molded onto the center of the bolt to prevent that. You can just slather on a spiral bead of silicone and do the same thing. The ringing bolt tends to break off right at the front iron in the threaded area."

end

something to think about....?

#1344

Excessive bolt adjustments may put them out of spec sooner than later... i would be careful with that. Keeping them in check is ok, fiddling with them excessively may not be that smart.

#1345

You definitely aren't, I was just expressing a little concern to make even less experienced members aware of the fact that our long-*** retaining bolts have their own tolerances and may have to be thrown away.