Possible New Renesis Engine Failure Theory?

#226

WENTGERMAN

iTrader: (6)

I am going to say that the placement of the side seal is for carbon buildup.

The keystone itself is buried in the rotor the only bit that sticks out is flat and resembles older 13b seals. ie the wedge cutout sees no action out of the rotor.

*Edit I realize Mazdas paperwork says this, I'm just trying to get a conversation going.

#230

Out of NYC

iTrader: (1)

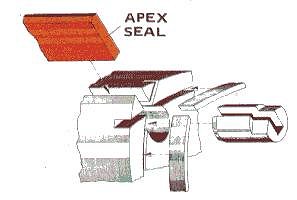

Thats part of the Apex seal. Mazda created like that because its better for start up sealing.

the whole graph is based on the FD's 3 piece RX-7 seal design. Our engine uses a 2 pc design. same thing for FC

the graph is ugly, however

Last edited by nycgps; 01-17-2011 at 06:00 PM.

#231

Registered

This is worth reading several times to raise the quality of the content on this thread. May I ask the kind favor of thinking twice before asking any questions that may appear poorly researched or rudimentary. Trust me, more smart people will comment on the topic when it doesn't get killed with entry level questions. There is a lot of good information in this article. Read it several times. Again, the kind favor of vomiting all over this thread with the info some people might only be thinking about for the first time. Keep this thread pure and value added.

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

#233

Out of NYC

iTrader: (1)

This is worth reading several times to raise the quality of the content on this thread. May I ask the kind favor of thinking twice before asking any questions that may appear poorly researched or rudimentary. Trust me, more smart people will comment on the topic when it doesn't get killed with entry level questions. There is a lot of good information in this article. Read it several times. Again, the kind favor of vomiting all over this thread with the info some people might only be thinking about for the first time. Keep this thread pure and value added.

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

I read the Japanese version years ago, the Japanese version has a bit more detail, but this is good enough

I want to freaking laugh at this part.

5.3. Optimizing Lubrication using Twin Direct Supply

The temperature of the corner seal of the side exhaust

port rises quicker than the peripheral exhaust port

because it is exposed to the exhaust ports. In addition,

lack of the oil film easily occurs when it passes the

exhaust ports, which is unfavorable for the lubrication.

In order to resolve these issues, two oil injection nozzles

for the gas seal lubrication were fitted to the rotor

housing to actively lubricate the rotor side faces. As

shown in Fig.30, this improved lubrication of the corner

seal, minimizing the amount of the lubrication oil. Fig.31

shows lubrication amount required for the each

lubrication system.

The temperature of the corner seal of the side exhaust

port rises quicker than the peripheral exhaust port

because it is exposed to the exhaust ports. In addition,

lack of the oil film easily occurs when it passes the

exhaust ports, which is unfavorable for the lubrication.

In order to resolve these issues, two oil injection nozzles

for the gas seal lubrication were fitted to the rotor

housing to actively lubricate the rotor side faces. As

shown in Fig.30, this improved lubrication of the corner

seal, minimizing the amount of the lubrication oil. Fig.31

shows lubrication amount required for the each

lubrication system.

Last edited by nycgps; 01-17-2011 at 06:16 PM.

#234

WENTGERMAN

iTrader: (6)

This is worth reading several times to raise the quality of the content on this thread. May I ask the kind favor of thinking twice before asking any questions that may appear poorly researched or rudimentary. Trust me, more smart people will comment on the topic when it doesn't get killed with entry level questions. There is a lot of good information in this article. Read it several times. Again, the kind favor of vomiting all over this thread with the info some people might only be thinking about for the first time. Keep this thread pure and value added.

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

Why couldn't someone say that 10 pages ago?

Last edited by shadycrew31; 01-17-2011 at 06:33 PM.

#237

WENTGERMAN

iTrader: (6)

Facts:

Faulty oil injectors can and will lead to premature engine failure.

These oil injectors are prone to failure but will never completely stop flowing.

The largest contributor to engine malfunction is carbon buildup.

The omp injects old engine oil into the combustion chamber to reduce heat and lubricate. One is a by product of another

By injecting old dirty engine oil in that is not really meant to be burnt it creates more carbon.

Conclusion:

Rotaries are ticking time bombs.

Options:

Buy a sohn adapter and run some 2 cycle oil in it.

Make sure your oil injectors are functional by performing a vacuum test on them.

Keep up with your maintenance

Purchase a set of BHR coils.

Faulty oil injectors can and will lead to premature engine failure.

These oil injectors are prone to failure but will never completely stop flowing.

The largest contributor to engine malfunction is carbon buildup.

The omp injects old engine oil into the combustion chamber to reduce heat and lubricate. One is a by product of another

By injecting old dirty engine oil in that is not really meant to be burnt it creates more carbon.

Conclusion:

Rotaries are ticking time bombs.

Options:

Buy a sohn adapter and run some 2 cycle oil in it.

Make sure your oil injectors are functional by performing a vacuum test on them.

Keep up with your maintenance

Purchase a set of BHR coils.

#239

Out of NYC

iTrader: (1)

These oil injectors are prone to failure but will never completely stop flowing.

The largest contributor to engine malfunction is carbon buildup.

The omp injects old engine oil into the combustion chamber to reduce heat and lubricate. One is a by product of another

By injecting old dirty engine oil in that is not really meant to be burnt it creates more carbon.

Conclusion:

Rotaries are ticking time bombs.

Rotaries are ticking time bombs.

Options:

Buy a sohn adapter and run some 2 cycle oil in it.

Buy a sohn adapter and run some 2 cycle oil in it.

see #3

Make sure your oil injectors are functional by performing a vacuum test on them.

Keep up with your maintenance

Purchase a set of BHR coils.

#241

SARX Legend

Thread Starter

iTrader: (46)

This is worth reading several times to raise the quality of the content on this thread. May I ask the kind favor of thinking twice before asking any questions that may appear poorly researched or rudimentary. Trust me, more smart people will comment on the topic when it doesn't get killed with entry level questions. There is a lot of good information in this article. Read it several times. Again, the kind favor of vomiting all over this thread with the info some people might only be thinking about for the first time. Keep this thread pure and value added.

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

http://www.rotarydevelopment.net/Rot...790_Rotary.pdf

Geesh, how can I not have seen this before somewhere? Thanks Eric.

Last edited by 9krpmrx8; 01-17-2011 at 09:52 PM.

#245

Super Moderator

#247

Registered

.....

-Various amounts of premix

When running in the above environment WITHOUT the OMP function we have experienced huge, huge, side seal spring failure. Huge. Please note that I did not use the word "Apex" anywhere in the previous sentence. We've had newly refreshed motors last 6 hours. We've had refreshed motors last 2 hours. Side seal spring failure with no OMP function.

Again, I could be wrong and our experience with the OMP has and does have a huge correlation to side seal spring failure. Not apex seal or corner seal. At all. We've been reusing the stock apex seals for a lonnnng time. We've also tried ceramics and they last so damn long its crazy (in our operating environment).

............

-Various amounts of premix

When running in the above environment WITHOUT the OMP function we have experienced huge, huge, side seal spring failure. Huge. Please note that I did not use the word "Apex" anywhere in the previous sentence. We've had newly refreshed motors last 6 hours. We've had refreshed motors last 2 hours. Side seal spring failure with no OMP function.

Again, I could be wrong and our experience with the OMP has and does have a huge correlation to side seal spring failure. Not apex seal or corner seal. At all. We've been reusing the stock apex seals for a lonnnng time. We've also tried ceramics and they last so damn long its crazy (in our operating environment).

............

I have a question trying to understand your findings:

You are claiming because you actually have seen it in a lot of open ups that under race conditions WITHOUT OMP BUT WITH PREMIX you get extremely wearing of side seals/springs.

Why PREMIX cannot lubricate the Side Seals/Springs whereas the OMP does.

Thanks

#248

Registered

Hi Eric ,

I have a question trying to understand your findings:

You are claiming because you actually have seen it in a lot of open ups that under race conditions WITHOUT OMP BUT WITH PREMIX you get extremely wearing of side seals/springs.

Why PREMIX cannot lubricate the Side Seals/Springs whereas the OMP does.

Thanks

I have a question trying to understand your findings:

You are claiming because you actually have seen it in a lot of open ups that under race conditions WITHOUT OMP BUT WITH PREMIX you get extremely wearing of side seals/springs.

Why PREMIX cannot lubricate the Side Seals/Springs whereas the OMP does.

Thanks

It is my belief that after sharing our repeated and consistant findings for about 16 engine failures that a few things are happening. This is speculative as it is very hard to MEASURE to confirm. Our spring failure mode is defined as a very thing spring thickness at the peaks and valleys. This is viewable to the naked eye. These are the points of contact where the side seal spring (a) touches the bottom of the side seal gland, (b) where the spring contacts the bottom of the side seal. Witness wear marks can be see on the spring, bottom of the seal and in the bottom of the gland.

My belief after sharing our findings with many smart race engine builders with many, many years of experience (and I talked to quite a few of them and sent them parts for analysis) is that this was happening WITHOUT the OMP

-The side seal was chattering on the iron surface as it made pass and pass after pass

-This may have generated more heat and the heat aided deterioration of the spring strength

-The chattering had an oscillating effect which led to spring travel up and down. I would presume that the spring in there was vibrating up and down at some crazy frequency which is impossible to measure

-.93 Lambda (making 220+ rwhp for us on a dynojet) added additional combustion heat (we would see approx 1,700F with .93) and this heat combined with the exhaust travel over the rotors chamfered edge furthur added additional heat to the side seal/spring area. Failures of the spring were not just isolated to that area chafered area exactly under the exhaust travel.

-Continued operation of the motor would lead to spring thinning to the point where it would break at the springs peaks or valleys thinnest location and this would cantilever the side seal and this would clip the port. This would snap the brittle side seal (usually about 1/3 of the way from the leading rotational edge of the rotor. This was ugly as the partial seal would fly around in the motor and scratch or gouge the hard parts which ofter require replacing.

-Intercepting this spring break by noticing when the motor was losing power avoided catatrophic failure (big $) which would require the car to be retired and a motor swap.

WITH the OMP and .89 Lambda

-EGT's were lowered by approx 100 over the .93 and no OMP

-Spring thickness rate loss was dramatically decreased and has allowed us to get less than 1% power loss after 20+ hour of WOT use in a racing environment. We have run the OMP on only 1 engine thus far for about 22 hours (same motor as above) before we pulled it apart. The springs showed wear and may have gone another 5 or 10 hours. We pulled it apart in a preemptive gesture to find out what was happening. Currently we are running our second motor with OMP at .89 Lambda to see if we can duplicate the results. Running 20+ hours on a race engine is expensive. Crew, fuel and tires (mostly tires) all add up. I prefer rubber that is most like that which we race on. Currently we use the R80 Radial Hoosier slick and these get about 3 honest hours of use. 888 Toyo about 2 hours or 3-4 heat cycles before it falls off. R6 acts like a different tire altogether but will last about 6-8 hours. To get the R6 to get the same grip as a Slick you have a run a pretty big tire and this is farther away from duplicating the spec tire we will race with in World Challenge next year: Pirelli slick hard compound. These tires run $1,300 a set and last a freakin hour.

My limited experience and lots and lots of $ have resulted in the belieft that the OMP squirters are located such so that they same the side seals which are getting new failure modes BECAUSE OF THE SIDE EXHAUST DESIGN

Up to 3 ounces of premix/gal were used with no OMP and the failure mode continued. My gut says this mist via the fuel injectors did not directly get placed where the OMP squirters were aimed. The premix was exactly limited to where the injectors squirt and either misted or wetted the intake ports and wherever that fuel charge travels when pushed/pulled during the intake process is where it landed and provided its lubricative (is that a word?) benefits.

This is my belief. I suspect some Mazda engineers who are probably retired by now could confirm it. Hope that answered your question.

The bottom line is we hooked the OMP back up and it solved our rapid spring deterioration and allows our motors to live much, much longer and sustain consistantly high power levels.

Note: We feed our OMP with the rotary aviation remote feed (which blocks off the pull of crankcase motor oil) and allows us to use a two stroke product. The OMP is not connected to any map and runs mechanically. Current rate of use is approx 1 qt per hour of WOT operation (give or take 10%). Turning up the manual dial on the OMP increases the rate of oil consumption and lowers the EGT by about 25F but limits car operation to about 1/2 hour (not long enough for us to run a full tank of fuel for an enduro or our 50 minute World Challenge races (plus parade and cool down laps). We have our OMP set so it runs approx a full tank of fuel at .89 Lambda.

Last edited by EricMeyer; 01-18-2011 at 06:37 AM.

The following users liked this post:

gracer7-rx7 (01-28-2020)