Turbo Oil Pressure Regulator

#126

SARX Legend

Thread Starter

iTrader: (46)

I wonder what BW recommends as max OP. I have push lock hoses and fittings for oil cooler lines as well, they have been that way for years now. With Oiteker clamps they can handle a lot of pressure and so far they have held up to the test of time. With the Kool Tool they are pretty easy to make as well.

#127

I do not know the details around the BW turbos, but only a orifice is not exactly a regulator, even if the pressure drop is exponential when oil flow gets turbulent(not laminate). But it might be good enough for the application.

#128

And one thing, I'm not an expert fitting guy, but the quick connectors might be a source of instability and hassle. I've experienced that in my profession. I'd definitively recommend no quick connectors if possible. If you have already made it permanent, keep an VERY close eye after disconnects/connects. Extremely hazardous.

#129

SARX Legend

Thread Starter

iTrader: (46)

Yes, this is exactly why I have the flow control regulator and the adjustable pressure relief valve on the bypass line. My engine has increased oil pressure so even at pretty low RPM it is significantly more than the turbo should see. We shall see though how long my turbo lasts this time, that will be the real test.

And one thing, I'm not an expert fitting guy, but the quick connectors might be a source of instability and hassle. I've experienced that in my profession. I'd definitively recommend no quick connectors if possible. If you have already made it permanent, keep an VERY close eye after disconnects/connects. Extremely hazardous.

#130

No respecter of malarkey

iTrader: (25)

You can't just take an apple and call it an orange ... well maybe the two of you can, but the rest of us know the difference between an apple and an orange when we see it.

They say absolutely don't do it on their turbo, but it's your wallet to decide what's best for yourself.

They say absolutely don't do it on their turbo, but it's your wallet to decide what's best for yourself.

#131

SARX Legend

Thread Starter

iTrader: (46)

Yeah pretty much everything I have read from every turbo manufacturer has said to not use a restrictor of any type on journal bearing and ball bearing turbos. Max pressure limits seem to vary by manufacturer a bit but most state no more than 60PSI at the turbo.

From the Borg Warner EFR Technical Training Guide:

Any input on this stuff is welcomed.

From the Borg Warner EFR Technical Training Guide:

Additional oil restrictions should not be used. The required restriction

to throttle the oil flow to the ball bearings is already integrated into the

bearing housing. The oil supply line should be kept as short as possible.

If a line of unusual length is required, we recommend a -6AN line

especially for very cold climates. -3AN line is not recommended due to

excessive oil supply delay times during cold start. We recommend that

oil reaches the turbo in less that 4 seconds during a cold start cranking,

and in under 1 second during hot-start conditions.

We often get questions about oil selection. The simplest answer is that

turbos prefer warm (but not overly hot), high viscosity (e.g. 10W40),

synthetic oil. Non-synthetic oils may of course be used but the user can

expect a higher degree of laquering and coking. Users of thin oil (e.g.

5W20) can expect lesser bearing system robustness against harsh

conditions or abuse, especially if the oil is very hot. Inlet oil pressure

(gage) is recommended to be at least 1bar (15psi) and not more than

4bar (60psi) under all “fully warmed-up” conditions.

to throttle the oil flow to the ball bearings is already integrated into the

bearing housing. The oil supply line should be kept as short as possible.

If a line of unusual length is required, we recommend a -6AN line

especially for very cold climates. -3AN line is not recommended due to

excessive oil supply delay times during cold start. We recommend that

oil reaches the turbo in less that 4 seconds during a cold start cranking,

and in under 1 second during hot-start conditions.

We often get questions about oil selection. The simplest answer is that

turbos prefer warm (but not overly hot), high viscosity (e.g. 10W40),

synthetic oil. Non-synthetic oils may of course be used but the user can

expect a higher degree of laquering and coking. Users of thin oil (e.g.

5W20) can expect lesser bearing system robustness against harsh

conditions or abuse, especially if the oil is very hot. Inlet oil pressure

(gage) is recommended to be at least 1bar (15psi) and not more than

4bar (60psi) under all “fully warmed-up” conditions.

Any input on this stuff is welcomed.

#132

No respecter of malarkey

iTrader: (25)

Well there's this too:

I supposed you'd have to call and ask them. However, this is for the BW-EFR apple, not the orange on your car ....

Dual Row Ceramic Ball Bearings - lowest friction and fastest spool/response, most extreme durability, built-in oil control orifice - (aka oil restrictor) **no restrictor can be used with EFR turbos

#133

SARX Legend

Thread Starter

iTrader: (46)

Yeah Greddy sucks at providing this type of information.

I did find this from Mitsubishi though. It leads me to believe that even my 60PSI max is too much. Mitsubishi makes the Greddy turbos. My center section is upgraded to a water cooled unit but it has the Mitsubishi logo cast into it.

1 kg/Cm2 =14.2 PSI

http://store.forcedperformance.net/m..._Oil_Specs.pdf

http://hondaswap.com/attachments/mit...ent-pdf.16265/

I have also read from a couple manufacturers that only ball bearing turbos come with the oil control orifice/restrictor built in.

I did find this from Mitsubishi though. It leads me to believe that even my 60PSI max is too much. Mitsubishi makes the Greddy turbos. My center section is upgraded to a water cooled unit but it has the Mitsubishi logo cast into it.

1 kg/Cm2 =14.2 PSI

http://store.forcedperformance.net/m..._Oil_Specs.pdf

http://hondaswap.com/attachments/mit...ent-pdf.16265/

I have also read from a couple manufacturers that only ball bearing turbos come with the oil control orifice/restrictor built in.

Last edited by 9krpmrx8; 04-05-2015 at 09:58 PM.

#138

Driving my unreliable rx8

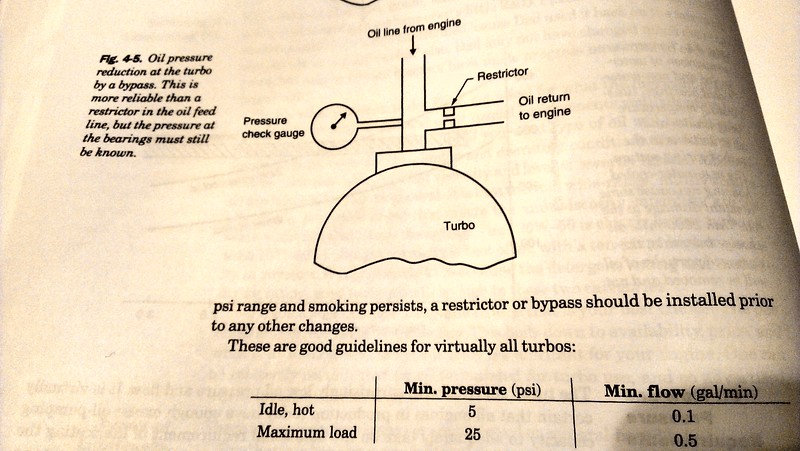

After running this for a while and getting it adjusted right I'm very happy with the results. My pressure is a little high from a cold start, and runs great once things start warming up. If I was going to do it again I think I'd skip the flow control and just go with a larger restriction then standard with the bypass. It gives the best of both worlds, plenty of flow with a set pressure.

#139

SARX Legend

Thread Starter

iTrader: (46)

After running this for a while and getting it adjusted right I'm very happy with the results. My pressure is a little high from a cold start, and runs great once things start warming up. If I was going to do it again I think I'd skip the flow control and just go with a larger restriction then standard with the bypass. It gives the best of both worlds, plenty of flow with a set pressure.

Yeah I am happy with mine thus far. I do plan on moving it and setting it up so that it is more universal should anyone else want one.

#143

SARX Legend

Thread Starter

iTrader: (46)

My setup is still working great.

A friend also shared this today:

Turbosmart Breathes Longer Life Into Your Turbo | Turbosmart

A friend also shared this today:

Turbosmart Breathes Longer Life Into Your Turbo | Turbosmart

#144

Registered

I still don't know a whole lot about oil pressure and turbos, but you were targeting 60 PSI. They only sell those at 40PSI. Do you think that's sufficient for your average greddy sized turbo?

#145

Yeah pretty much everything I have read from every turbo manufacturer has said to not use a restrictor of any type on journal bearing and ball bearing turbos. Max pressure limits seem to vary by manufacturer a bit but most state no more than 60PSI at the turbo.

From the Borg Warner EFR Technical Training Guide:

Any input on this stuff is welcomed.

From the Borg Warner EFR Technical Training Guide:

Any input on this stuff is welcomed.

I figured I would add... CompTurbo explicitly told me I must use a restrictor with the ball bearing turbo I got. IIRC it is somewhere around 0.018". I think it just depends on whether one is built in or not.

I figured I would add... CompTurbo explicitly told me I must use a restrictor with the ball bearing turbo I got. IIRC it is somewhere around 0.018". I think it just depends on whether one is built in or not.

#146

SARX Legend

Thread Starter

iTrader: (46)

Most turbos would be fine around the 40psi mark, 60psi is on the higher end of the scale.

Just read what the actual turbo manufacturers recommend and you will get an idea.

#147

Registered

I've got a Greddy turbo that was modified by BNR. I'd hate to bother Bryan over the same issue you already spoke to him about. He said 10PSI per 1k RPM max, but did he give any minimum recommended pressures? If not I can always try hitting him up.

On a side note, did you ever put together any of those kits you were talking about? I'd grab one in a heartbeat. I know if I pieced it together myself it probably wouldn't end too well.

On a side note, did you ever put together any of those kits you were talking about? I'd grab one in a heartbeat. I know if I pieced it together myself it probably wouldn't end too well.

#149

No respecter of malarkey

iTrader: (25)

not to say it won't work, but they didn't intend it for that application to begin with ...

Turbosmartís new patent pending OPR T40 is an oil pressure regulation system for your ball bearing turbocharger. It helps prevent compressor or turbine stage oil leaking or smoking, and takes the guesswork out of oil restrictor sizing for more efficient and effective oil delivery.

#150

Registered

I definitely appreciate it. Does having a water cooled bearing housing not affect it at all? I can't fathom how it would.

For anyone who doesn't feel like doing the math.

Idle - 11-12 PSI

Recommended at full load - 42-50 PSI

So while that pressure regulator might work, it's definitely on the low end of what's acceptable.

Good point, I'm still trying to learn the nuances about my turbo and how it relates to others. I've mostly taken it for granted and focused elsewhere.