Bridge Porting the Renesis

#101

Good infos Erick and out of curiosity, what would you do to the exhaust headers considering that the design of ours is meant to work with a 0 overlap engine?

I mean, could we find some gains there at this point or would they all work like actual headers work on stock engines?

I mean, could we find some gains there at this point or would they all work like actual headers work on stock engines?

#105

Honestly, after seeing a lot of this up close and the various discussions, the conclusion I've come to is the following:

Assuming the bridge porting can be completed, I believe that it would seriously compromise the integrity of the motor in such a way that it would shorten the operational life. At the same time, due to the need to keep the port small I can't see there being much power benefits which cannot be obtained via other means.

I understand much of the discussion has been whether or not the bridge porting is even possible. I believe it is but at great expense with little gain. If sound is all you're looking for then there's nothing I can do to help you.

#106

No respecter of malarkey

iTrader: (25)

I think "you" confused "me" with someone else:

https://www.rx8club.com/showpost.php...&postcount=140

otherwise I'm completely open to the idea that my theoretical ideas are totally fubar, stated again so I don't get confused with anyone else

https://www.rx8club.com/showpost.php...&postcount=140

otherwise I'm completely open to the idea that my theoretical ideas are totally fubar, stated again so I don't get confused with anyone else

Looking at the motor in question Easy has been using and speaking to him the primary and secondary ports are lined up so if you ported the secondary it would still see overlap. The issue with porting the auxillary port is the actual valve is only sized for the opening of that port. So, in theory, porting the auxillary port wouldn't work because there would be no way to deliver the air to the extended port area.

Honestly, after seeing a lot of this up close and the various discussions, the conclusion I've come to is the following:

Assuming the bridge porting can be completed, I believe that it would seriously compromise the integrity of the motor in such a way that it would shorten the operational life. At the same time, due to the need to keep the port small I can't see there being much power benefits which cannot be obtained via other means.

I understand much of the discussion has been whether or not the bridge porting is even possible. I believe it is but at great expense with little gain. If sound is all you're looking for then there's nothing I can do to help you.

Honestly, after seeing a lot of this up close and the various discussions, the conclusion I've come to is the following:

Assuming the bridge porting can be completed, I believe that it would seriously compromise the integrity of the motor in such a way that it would shorten the operational life. At the same time, due to the need to keep the port small I can't see there being much power benefits which cannot be obtained via other means.

I understand much of the discussion has been whether or not the bridge porting is even possible. I believe it is but at great expense with little gain. If sound is all you're looking for then there's nothing I can do to help you.

#107

Haha, sorry I didn't mean to direct that statement at you...when it came out it was more generalized. I know you're not looking for sound.

There have been people commenting in the various threads about the "sound" of the porting. That's what it is in reference to. Sorry for the confusion.

There have been people commenting in the various threads about the "sound" of the porting. That's what it is in reference to. Sorry for the confusion.

#108

No respecter of malarkey

iTrader: (25)

Haha, sorry I didn't mean to direct that statement at you...when it came out it was more generalized. I know you're not looking for sound.

There have been people commenting in the various threads about the "sound" of the porting. That's what it is in reference to. Sorry for the confusion.

There have been people commenting in the various threads about the "sound" of the porting. That's what it is in reference to. Sorry for the confusion.

#110

It'd flow more anyway simply by being open a little longer if you end up going with some overlap, and there's nothing to stop you opening the inside of the valve up to flow more air anyway.

#114

13B-RE

iTrader: (1)

I have been giving the Renesis much thought in the last couple days....I am building one as we speak...I am debating on what to do....Even bridging the exhaust port would increase duration of the exhaust stroke and cause overlap....I don't know how much heat that bridge will be able to take....

Combining both bridges (intake and exhaust) would cause as much overlap as a peripheral exhaust, bridge ported REW engine.....

I just worry about having all this intake area....and not nearly enough exhaust port area....this could cause detonation of incoming air/fuel mixture if there is exhaust that didn't exit the camber getting combined with incoming fresh air/fuel due to the overlap....

Of course I am thinking Turbo here.

any thoughts/suggestions?

Chris

Last edited by ChrisRX8PR; 06-10-2009 at 01:02 PM.

#115

13B-RE

iTrader: (1)

Oh, and on your apex seal issue with position....the Half bridge guys that only bridge the front and rear plates just install the rear apex seals backwards so the small corner runs on the non-bridged center plate/housing like the front apex does. That way there is no issues with the small corner falling into the port due to the notch in the housing.

Chris

Chris

#116

Registered

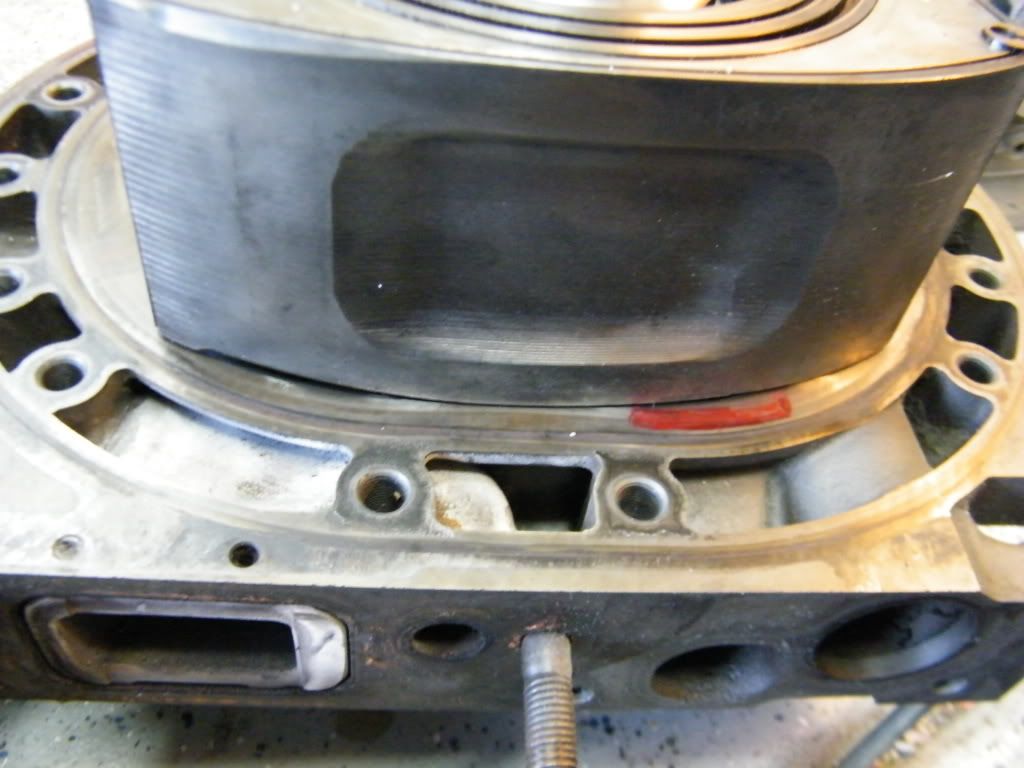

You can not bridge a Renesis exhaust port. Besides the fact that it wouldn't survive in that temp extreme even if it could be done, the water jacket is in the way. It sounds weird but take a close look. It can't be done.

As far as removing the exhaust sleeve, there's no point in it. You don't increase exhaust port area. You increase the runner area which slows down the exhaust gas speed. It's not an area problem that those ports have. It's a port to runner transition that's an issue and sadly doesn't look to be terribly feasible to improve significantly.

As far as removing the exhaust sleeve, there's no point in it. You don't increase exhaust port area. You increase the runner area which slows down the exhaust gas speed. It's not an area problem that those ports have. It's a port to runner transition that's an issue and sadly doesn't look to be terribly feasible to improve significantly.

#117

13B-RE

iTrader: (1)

You can not bridge a Renesis exhaust port. Besides the fact that it wouldn't survive in that temp extreme even if it could be done, the water jacket is in the way. It sounds weird but take a close look. It can't be done.

As far as removing the exhaust sleeve, there's no point in it. You don't increase exhaust port area. You increase the runner area which slows down the exhaust gas speed. It's not an area problem that those ports have. It's a port to runner transition that's an issue and sadly doesn't look to be terribly feasible to improve significantly.

As far as removing the exhaust sleeve, there's no point in it. You don't increase exhaust port area. You increase the runner area which slows down the exhaust gas speed. It's not an area problem that those ports have. It's a port to runner transition that's an issue and sadly doesn't look to be terribly feasible to improve significantly.

And that is what I was worried about. I was going go look at some plates I have in the garage, I couldn't remember if there was water in that specific area where a bridge would sit. Thanks for clearing that up....

The person that removed the exhaust sleeves ported around the remaining metal to make the transition as smooth as possible(not perfect by any means but better) and he saw improvement...the cost was heat into the coolant jacket...

What do you think RG? For turbo, do you think the stock exhaust ports have enough area/duration to warrant a bridge on the intake? I know you don't like bridges in general but I wanted to hear your opinion.

Best regards,

Chris

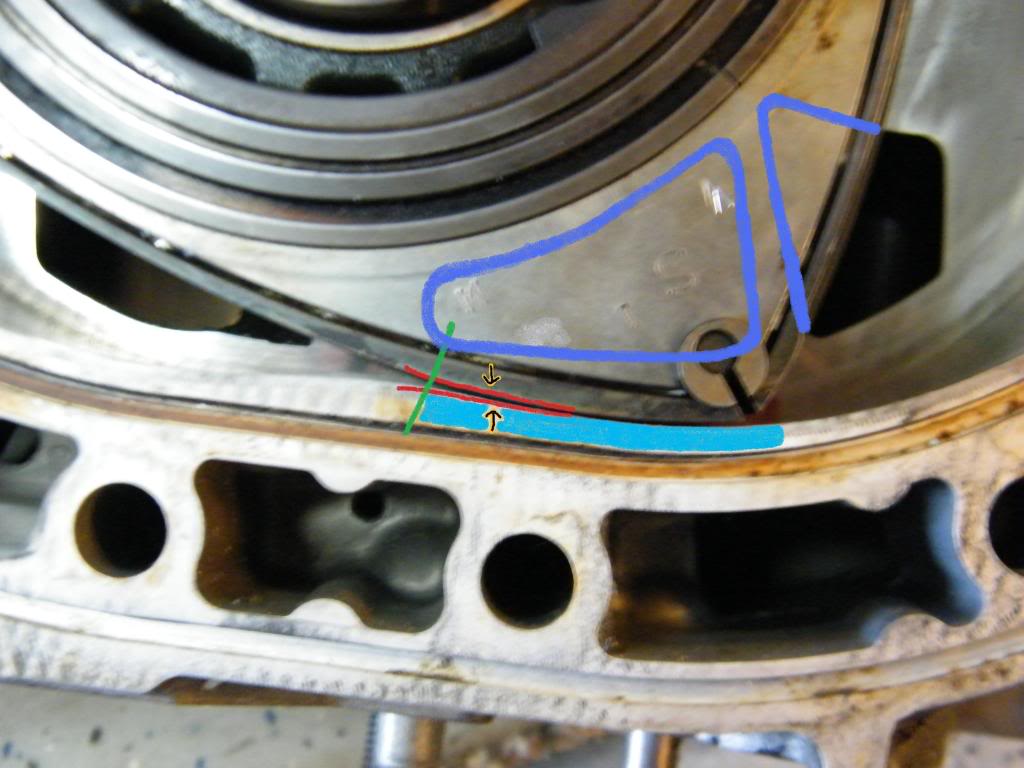

Edit: I saw significant gains from opening up the exhaust port downward (earlier) about 1/8" of an inch and porting the intake ports into the edge of the oil control rings and up wards (closing later) but I didn't have any space to open outwards toward the housing on either intake or exhaust ports because the corner seals would fall in.

Last edited by ChrisRX8PR; 06-10-2009 at 01:27 PM.

#118

13B-RE

iTrader: (1)

Ok, so I experimented with one of the extra plates I have. It appeared as though there is enough meat to create a bridgeport so I went ahead and made one and it looks great and doesn't seem like it will interfere with any of the seals and it should provide ample support to the corner seal and apex seal. You must however notch the housing to get the best of it but since I was thinking of doing this only on the front and rear plates then I just have to face the small apex seal corner towards the center plate for both rotors to prevent it from binding.

I checked the exhaust and the water jacket is all around that area so not bridgeport is possible even if it could take the heat.

To the OP: Did your builder/mechanic bridge port all three plates? or did he just do the front and rear? and if he did, did he notch the housings?

I am just wondering from an apex seal standpoint.

Anyone else have any input?

Best regards,

Chris

I checked the exhaust and the water jacket is all around that area so not bridgeport is possible even if it could take the heat.

To the OP: Did your builder/mechanic bridge port all three plates? or did he just do the front and rear? and if he did, did he notch the housings?

I am just wondering from an apex seal standpoint.

Anyone else have any input?

Best regards,

Chris

#119

Registered

I'm not against bridgeports at all. I just think there are certain plates that they are suited for and that they should only be used for off road (track) use. On the 7 forum they think I'm against bridging too. I'm not. The problem is that everyone over there seems to be bridging the 6 port motors and then retaining the factory intake manifolds and ecu's that require a restrictive airflow meter. That's a terrible setup and never makes more power than even a moderate streetport.

I've always been a firm believer that 6 port housings should not be bridged. I still feel the same way on the Renesis but now it's a lack of sufficient material in that area (in my opinion) that completely disqualifies it to me. Had the Renesis intake ports not opened so early leaving more room then I'd be more prone to try it and even then I'd favor doing it to the old 4 port Renesis housings instead.

I've always been a firm believer that 6 port housings should not be bridged. I still feel the same way on the Renesis but now it's a lack of sufficient material in that area (in my opinion) that completely disqualifies it to me. Had the Renesis intake ports not opened so early leaving more room then I'd be more prone to try it and even then I'd favor doing it to the old 4 port Renesis housings instead.

#120

13B-RE

iTrader: (1)

I'm not against bridgeports at all. I just think there are certain plates that they are suited for and that they should only be used for off road (track) use. On the 7 forum they think I'm against bridging too. I'm not. The problem is that everyone over there seems to be bridging the 6 port motors and then retaining the factory intake manifolds and ecu's that require a restrictive airflow meter. That's a terrible setup and never makes more power than even a moderate streetport.

I've always been a firm believer that 6 port housings should not be bridged. I still feel the same way on the Renesis but now it's a lack of sufficient material in that area (in my opinion) that completely disqualifies it to me. Had the Renesis intake ports not opened so early leaving more room then I'd be more prone to try it and even then I'd favor doing it to the old 4 port Renesis housings instead.

I've always been a firm believer that 6 port housings should not be bridged. I still feel the same way on the Renesis but now it's a lack of sufficient material in that area (in my opinion) that completely disqualifies it to me. Had the Renesis intake ports not opened so early leaving more room then I'd be more prone to try it and even then I'd favor doing it to the old 4 port Renesis housings instead.

.

.I see what you are saying...in my case however...I have the intake manifold, turbo and fuel management to take advantage of bridging....I understand your point that the hassle might not make it worth while for the power gained minus the loss down low...but I might just try it to see where it goes...maybe it will suck and I will be sorry but maybe it won't....

BTW, I have though about using 4 port irons.....and doing a full street/bridge port on the reni....but then I just wasted all that plenum piping etc that I have feeding the aux ports......hmmmm. I'll think about it....

What do you think about this?

What do you think about this?Chris

#122

Registered

I'm definitely not against experimentation. I try new things all the time. Most I don't even bother to share publicly as some of them are just whacky things I do for purely educational purposes. What I've been working on this week is a prime example although not really that out there. I'm revisiting something I tried many years ago and something that is common on piston engines. It's nothing serious. Yesterday I spent about 3 hours with a die grinder hogging out an '89 RX-7 dynamic chamber. The best way to describe it from the factory is a "dual plane manifold" although even that may be simplifying it a little. Mine is now a "single plane manifold". I am not trying to claim that it will improve power. I am more interested in how it will change the powerband and how the stock ecu will respond to it. Then I want to retune it and see if there is any benefit. Luckily I have 4 of these manifolds lying around and the ability to tune the ecu so I can try lots of things. When I tried this years ago, I had no tuning capability and that car wasn't even running like it should have been anyways. I was trying too many things at once back then and it's pretty hard to learn that way!

I am also using a G-tech pro to create a "dyno chart" of the runs with each setup. I'm actually not concerned in the least what the power output of each is. All I care about is comparing the power curves of each to each other to see where they are different and if there is an advantage of using each one depending on the situation. If I posted this on the 7 forum, they'd ask to see a real dyno and then just complain about how much power the car does or doesn't make and wouldn't focus on the change in powerband. It would also get misinterpreted as a claim that this is better and that's not the point. Learning is.

I am also playing with a magnahelic gauge right now paying attention to pressure losses through the intake system before the throttlebody on that car in an attempt to show that yes the airflow meter really does rob horsepower. Many think it doesn't. Part of this is also to see how to implement a true ram air system effectively and if it is even possible within the space constraints that I have to work with. Maybe, maybe not. Even if it is, it doesn't mean it's worth the effort. That too isn't the point. I also have a little object sitting in my room right now that will get installed at some point but I'm not saying what that is. It is something that the rotary community has never really embraced though. I'm also going to try some new exhaust ideas but right now it's one thing at a time. That's in line though. I've really always been known as an airflow person anyways.

So you see, I'm not against experimentation. Have fun with porting. If I mess up an intake manifold, it's not too expensive to replace and not too hard to fix. Experimenting with engines is a bit more expensive and time consuming if it doesn't work out right. I'd love to build a nice bridgeported engine. I've actually ported one but it wasn't mine and unfortunately that kid didn't set the rest of the system up correctly as he was told to. Brian Cain is also one of my best rotary friends and is probably about as good as they come in regards to engine porting and bridging. We bounce ideas off of each other all the time. I do know he's got ideas in regards to bridging the Renesis. If you are willing to tackle bridging on this engine, go for it! Share the results. We'd all love to find out if something works on this engine that didn't on the 13B.

I am also using a G-tech pro to create a "dyno chart" of the runs with each setup. I'm actually not concerned in the least what the power output of each is. All I care about is comparing the power curves of each to each other to see where they are different and if there is an advantage of using each one depending on the situation. If I posted this on the 7 forum, they'd ask to see a real dyno and then just complain about how much power the car does or doesn't make and wouldn't focus on the change in powerband. It would also get misinterpreted as a claim that this is better and that's not the point. Learning is.

I am also playing with a magnahelic gauge right now paying attention to pressure losses through the intake system before the throttlebody on that car in an attempt to show that yes the airflow meter really does rob horsepower. Many think it doesn't. Part of this is also to see how to implement a true ram air system effectively and if it is even possible within the space constraints that I have to work with. Maybe, maybe not. Even if it is, it doesn't mean it's worth the effort. That too isn't the point. I also have a little object sitting in my room right now that will get installed at some point but I'm not saying what that is. It is something that the rotary community has never really embraced though. I'm also going to try some new exhaust ideas but right now it's one thing at a time. That's in line though. I've really always been known as an airflow person anyways.

So you see, I'm not against experimentation. Have fun with porting. If I mess up an intake manifold, it's not too expensive to replace and not too hard to fix. Experimenting with engines is a bit more expensive and time consuming if it doesn't work out right. I'd love to build a nice bridgeported engine. I've actually ported one but it wasn't mine and unfortunately that kid didn't set the rest of the system up correctly as he was told to. Brian Cain is also one of my best rotary friends and is probably about as good as they come in regards to engine porting and bridging. We bounce ideas off of each other all the time. I do know he's got ideas in regards to bridging the Renesis. If you are willing to tackle bridging on this engine, go for it! Share the results. We'd all love to find out if something works on this engine that didn't on the 13B.

#123

I am also playing with a magnahelic gauge right now paying attention to pressure losses through the intake system before the throttlebody on that car in an attempt to show that yes the airflow meter really does rob horsepower. Many think it doesn't. Part of this is also to see how to implement a true ram air system effectively and if it is even possible within the space constraints that I have to work with.

#124

I am also using a G-tech pro to create a "dyno chart" of the runs with each setup. I'm actually not concerned in the least what the power output of each is. All I care about is comparing the power curves of each to each other to see where they are different and if there is an advantage of using each one depending on the situation.