Issues with Fuel Pump install

#1

U-Stink-But-I-♥-U

Thread Starter

iTrader: (1)

Join Date: Mar 2005

Location: 12 o'clock on the Beltway.

Posts: 2,004

Likes: 0

Received 1 Like

on

1 Post

Issues with Fuel Pump install

I hate to start another cluttering thread, but I cannot find the info I need. During the installation of a new fuel pump I had a few issues. I would ask that the thread stay on topic answering THE ISSUES and not become a soap box upon which to vent. I understand that there are peripheral issues related to the vendor of the pump, but this is not the place to discuss them. Also, if you don't KNOW what you are talking about, don't post. I am not interested in your opinion.

I have three issues. First, I scuffed one of the electrical wires coming out of the fuel tank into the pump and a little metal is now showing. I could think of NO safe way to cover this so opted to simply reinstall, thinking that 1) there is no way to short as there is no way to complete a circuit and 2) the mix in a fuel tank should be pretty rich, thus not combustible. I have one suggestion through PM suggesting I use some heat shrink, but that would entail finding the other end of the wire to remove it and work on it outside the tank. I did not see the other end of the wire when I was in there (I was a little woozy from fumes.) Is this an issue requiring remedy? (I am not asking for posts that say "I would never drive around with an exposed wire in my gas tank! Safety First!" If you look EVERY tank has exposed metal at the connectors.)

Second, I found it very easy to get the retaining ring off and on and that worries me as most folks have had a rough time. Your experience? On reinstall, I was able to spin the retaining ring about 180 degrees, but because my fingers were cold and slick from fuel, I was not able to turn it with my hands a full turn; however, I was able to tighten it beyond a full turn. My intention is to wait to reinstall the cover so that I can observe any sloshing or leaking on cornering. Is this advised?

Finally, the mazsport fuel pump has a semi-return system (return does not come from the fuel rail, which would be more optimal methinks) with a regulator (rising rate?). The unit arrived disassembled with no picture instructions, only written instructions that referred to pictures. I am assuming that the attached hose containing the regulator forms a loop at the top of the pump. A loop makes sense as it would allow for excess fuel to return right back to the pickup. If this is the case it is a pretty tight fit, but I guess that is how it works. Could someone that has seen or installed the Mazsport unit post a description of the top of the pump once installed? Also, where is the best place to plumb the pressure line from the regulator? Should this go as close as possible to the turbo, i.e., on a tapped line on the turbo outlet?

THanks in advance for the help.

I have three issues. First, I scuffed one of the electrical wires coming out of the fuel tank into the pump and a little metal is now showing. I could think of NO safe way to cover this so opted to simply reinstall, thinking that 1) there is no way to short as there is no way to complete a circuit and 2) the mix in a fuel tank should be pretty rich, thus not combustible. I have one suggestion through PM suggesting I use some heat shrink, but that would entail finding the other end of the wire to remove it and work on it outside the tank. I did not see the other end of the wire when I was in there (I was a little woozy from fumes.) Is this an issue requiring remedy? (I am not asking for posts that say "I would never drive around with an exposed wire in my gas tank! Safety First!" If you look EVERY tank has exposed metal at the connectors.)

Second, I found it very easy to get the retaining ring off and on and that worries me as most folks have had a rough time. Your experience? On reinstall, I was able to spin the retaining ring about 180 degrees, but because my fingers were cold and slick from fuel, I was not able to turn it with my hands a full turn; however, I was able to tighten it beyond a full turn. My intention is to wait to reinstall the cover so that I can observe any sloshing or leaking on cornering. Is this advised?

Finally, the mazsport fuel pump has a semi-return system (return does not come from the fuel rail, which would be more optimal methinks) with a regulator (rising rate?). The unit arrived disassembled with no picture instructions, only written instructions that referred to pictures. I am assuming that the attached hose containing the regulator forms a loop at the top of the pump. A loop makes sense as it would allow for excess fuel to return right back to the pickup. If this is the case it is a pretty tight fit, but I guess that is how it works. Could someone that has seen or installed the Mazsport unit post a description of the top of the pump once installed? Also, where is the best place to plumb the pressure line from the regulator? Should this go as close as possible to the turbo, i.e., on a tapped line on the turbo outlet?

THanks in advance for the help.

#2

The Professor

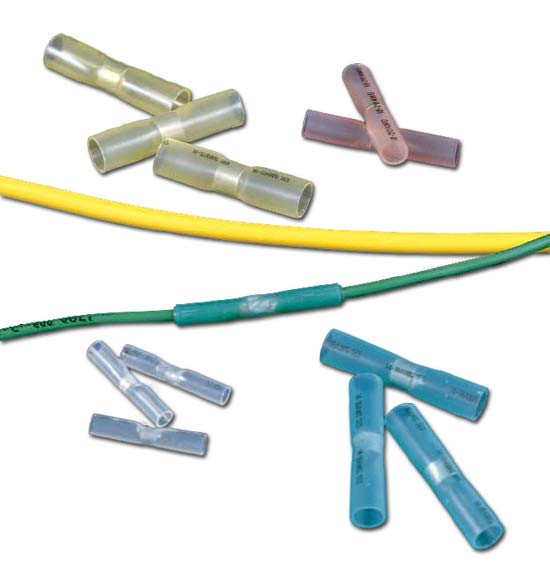

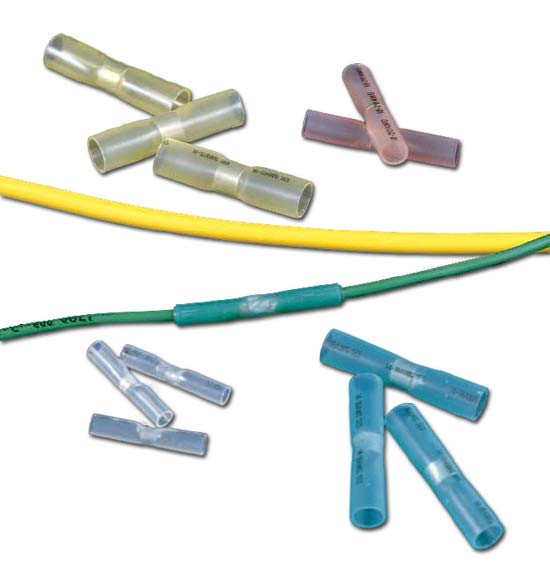

I'm thinking that the wire you accidentally hit was the fuel level sensor. It should be ok if just a small portion of it was exposed. If it really bothers you though, you could cut out at section and use some sealing splices

Just be sure to try and make both wires as equal as possible to avoid differences in resistance. So cut off about 1/2 in of the damaged section then cut out 1/2 an inch on the other side and put in the splice on the undamaged wire also.

Just be sure to try and make both wires as equal as possible to avoid differences in resistance. So cut off about 1/2 in of the damaged section then cut out 1/2 an inch on the other side and put in the splice on the undamaged wire also.

#3

U-Stink-But-I-♥-U

Thread Starter

iTrader: (1)

Join Date: Mar 2005

Location: 12 o'clock on the Beltway.

Posts: 2,004

Likes: 0

Received 1 Like

on

1 Post

So those are just crimp splices? THat is a good idea. And also, good idea to keep the lengths the same. I think I will just wait to see if I have a leak, then if I need to go back in, I will have the parts ready and fix it then.

Any info on the config. of the semi-return tubing?

Any info on the config. of the semi-return tubing?

#4

Banned

iTrader: (3)

1) Crimp splice as indicated above. Always the best method in an automotive environment as solder or something similar fails.

2) I think I have the installation instructions WITH pictures. Gimme a couple of hours to find it. (MYSQL probably has it, too.)

3) I think you would want the FPR reference to be the manifold, so get it from the same place as your WG signal.

2) I think I have the installation instructions WITH pictures. Gimme a couple of hours to find it. (MYSQL probably has it, too.)

3) I think you would want the FPR reference to be the manifold, so get it from the same place as your WG signal.

#5

First, I scuffed one of the electrical wires coming out of the fuel tank into the pump and a little metal is now showing. I could think of NO safe way to cover this so opted to simply reinstall, thinking that 1) there is no way to short as there is no way to complete a circuit and 2) the mix in a fuel tank should be pretty rich, thus not combustible.

Yes and no to 1) & 2).

Flowing fuel under pressure can create static electricty. There are many ways that this is handled in fuel pump design. 1) Ground components so that static electricity can never build up; or 2) Don't give the static charge anywhere do discharge to, thus preventing the spark.

Static electricity can discharge from a fuel line to a metal component on the fuel pump module. i.e. the metal rods from the lower portion to the flange. This may not cause a "thermal event" but it can burn holes in fuel lines within the tank. You may not start a fire but you can lose pressure if you get a hole in a line.

Which wire did you scuff? Kind of hard to tell. If it was the pump wires I would make sure to fix it properly. Shrink wrap can work but make sure it's rated for use in fuel. Plain old shrink wrap can degrade over time in fuel. If it was the sender gage wire I would still fix it with proper shrink wrap but wouldn't be as worried since it's fairly low voltage (as mentioned above in previous post). Not exactly sure of the Mazda system but sender gage circuits are typically ~5V.

To start a fire you need 3 things 1) Fuel (gasoline in this case); 2) Oxygen; and 3) A spark. Remove any one of the 3 and combustion is impossible. Example: A spark below the surface of fuel won't start a fire due to lack of oxygen.

#7

The Professor

Oh and one more thing. Uh, be extremely careful how you shrink that tubing. Don't want to see you get exploded if you try and use a lighter or heat gun near the open fuel tank.

#8

U-Stink-But-I-♥-U

Thread Starter

iTrader: (1)

Join Date: Mar 2005

Location: 12 o'clock on the Beltway.

Posts: 2,004

Likes: 0

Received 1 Like

on

1 Post

Heh, yeah. That would be bad.

I am going to leave the nicked wire alone unless I have to get back in there. I talked to my bro-in-law mechanic and he suggested that many fuel level sensors use a very low voltage resistance sensor. So the only risk is that the fuel level sensor may not work appropriately (will show a full tank) if a short is generated. Thanks for the advice.

I am still wondering if anyone has a pic or description of the Mazsport fuel pump install.

I will tee-off the manifold wg vac line for the regulator.

I am going to leave the nicked wire alone unless I have to get back in there. I talked to my bro-in-law mechanic and he suggested that many fuel level sensors use a very low voltage resistance sensor. So the only risk is that the fuel level sensor may not work appropriately (will show a full tank) if a short is generated. Thanks for the advice.

I am still wondering if anyone has a pic or description of the Mazsport fuel pump install.

I will tee-off the manifold wg vac line for the regulator.

#9

Heh, yeah. That would be bad.

I am going to leave the nicked wire alone unless I have to get back in there. I talked to my bro-in-law mechanic and he suggested that many fuel level sensors use a very low voltage resistance sensor. So the only risk is that the fuel level sensor may not work appropriately (will show a full tank) if a short is generated. Thanks for the advice.

I am still wondering if anyone has a pic or description of the Mazsport fuel pump install.

I will tee-off the manifold wg vac line for the regulator.

I am going to leave the nicked wire alone unless I have to get back in there. I talked to my bro-in-law mechanic and he suggested that many fuel level sensors use a very low voltage resistance sensor. So the only risk is that the fuel level sensor may not work appropriately (will show a full tank) if a short is generated. Thanks for the advice.

I am still wondering if anyone has a pic or description of the Mazsport fuel pump install.

I will tee-off the manifold wg vac line for the regulator.

I haven't personally seen the '09 pump. I think I may know who supplies it though.

Actually I'm sitting at a desk on an island as we speak right now. I should go bug the guys over here to see it.

#10

Zoom-Freakin'-Zoom

iTrader: (5)

Not always true. A lot of the OEMs now do the complete opposite. If the ECU detects some type of sender gage failure and sets the check engine light they will drive the gage on the cluster to E. Who wants to be driving around thinking they have a full tank when they actually are near empty? Not only due to the inconvience but safety. Doing 70mph down a highway and suddenly loosing power because of an empty tank = bad.

Thanks OD. Still around. I really don't post too much, only when I can help out.

I haven't personally seen the '09 pump. I think I may know who supplies it though.

Actually I'm sitting at a desk on an island as we speak right now. I should go bug the guys over here to see it.

Thanks OD. Still around. I really don't post too much, only when I can help out.

I haven't personally seen the '09 pump. I think I may know who supplies it though.

Actually I'm sitting at a desk on an island as we speak right now. I should go bug the guys over here to see it.

i am making franken pump!

glad you are still around..

carbon.. hot air gun ftw.

beers

#11

Registered

iTrader: (3)

Franken Pump!!! I am lmmfao dude!!!!! My Jack Russells are thinking I am having a seizure! AH man---that was better than sex----wait a min--what did I just say?

Franken pump---ah **** ----hahahahahahahahaha!!!!

Ok Ok enough. Jesus

Good to know the pump is coming from a good source--somewhere.

replaceable filter now, different sock, redesigned venturi it seems--maybe getting it right. I have one coming end of month holding off installing the external filter until i see this thing.

holding off installing the external filter until i see this thing.

Stay with us howard!

Franken Pump------man you are killing me here!!!!!

HAHAHAHAHAHAHAHAHAHAHAHAHAHAHAHA

olddragger

Franken pump---ah **** ----hahahahahahahahaha!!!!

Ok Ok enough. Jesus

Good to know the pump is coming from a good source--somewhere.

replaceable filter now, different sock, redesigned venturi it seems--maybe getting it right. I have one coming end of month

holding off installing the external filter until i see this thing.

holding off installing the external filter until i see this thing.Stay with us howard!

Franken Pump------man you are killing me here!!!!!

HAHAHAHAHAHAHAHAHAHAHAHAHAHAHAHA

olddragger

#12

Zoom-Freakin'-Zoom

iTrader: (5)

Franken Pump!!! I am lmmfao dude!!!!! My Jack Russells are thinking I am having a seizure! AH man---that was better than sex----wait a min--what did I just say?

Franken pump---ah **** ----hahahahahahahahaha!!!!

Ok Ok enough. Jesus

Good to know the pump is coming from a good source--somewhere.

replaceable filter now, different sock, redesigned venturi it seems--maybe getting it right. I have one coming end of month holding off installing the external filter until i see this thing.

holding off installing the external filter until i see this thing.

Stay with us howard!

Franken Pump------man you are killing me here!!!!!

HAHAHAHAHAHAHAHAHAHAHAHAHAHAHAHA

olddragger

Franken pump---ah **** ----hahahahahahahahaha!!!!

Ok Ok enough. Jesus

Good to know the pump is coming from a good source--somewhere.

replaceable filter now, different sock, redesigned venturi it seems--maybe getting it right. I have one coming end of month

holding off installing the external filter until i see this thing.

holding off installing the external filter until i see this thing.Stay with us howard!

Franken Pump------man you are killing me here!!!!!

HAHAHAHAHAHAHAHAHAHAHAHAHAHAHAHA

olddragger

ah,

i make you laugh.. funny.. lots of stuff we talked about at rr, is kinda going to get worked into the my quest for an answer..

for the most part it is very simple.. and we talked about most of it! i have a slow building thread covering what is going on..

but just to make you photo jealous.. i just learned how to do this..

looks clean and good. well you cant suck or blow any thing by it and it is worse when wet!!!!

beers

#14

U-Stink-But-I-♥-U

Thread Starter

iTrader: (1)

Join Date: Mar 2005

Location: 12 o'clock on the Beltway.

Posts: 2,004

Likes: 0

Received 1 Like

on

1 Post

The hijack is fine.

Any body got a pic of the mazsport install instructions (the one with pics.) I am pretty sure I know what to do, but I dont like being pretty sure.

Any body got a pic of the mazsport install instructions (the one with pics.) I am pretty sure I know what to do, but I dont like being pretty sure.

Thread

Thread Starter

Forum

Replies

Last Post

Audio Concepts ATL

New Member Forum

21

09-26-2021 01:59 PM

dbarber

Series I Trouble Shooting

14

07-25-2015 01:34 PM