Kickers V6 swap thread

#776

Registered

Thread Starter

I think the 5252 cross only when using Imperial measurement. Metric gets weird. I tried reading into it but got bored.

#777

Registered

Thread Starter

Well I finally found something I can grief Isuzu about... The head bolts.

They are a PAIN IN THE *** to get out. They have 10mm hex heads and the threads start about 1-1/2" below the deck. On the first engine, I only broke one and was able to get it out with an overnight soak of PB and an EZ out but they are really hard to drill. The second engine, I managed to strip the head on one bolt (not a big deal) but broke three others on the same side.

Hopefully I can save this block for a spare but I still have the first one prepped so there's no setbacks.

EDIT - Got both heads off. This block still has a very clear crosshatch and zero ring ridge. If I can get the three bolts out I'll probably end up using this block. Ug... I have to do all that cleaning again.

There's an engine shop in town that opened up a few years ago. I finally had a chance to drop in today to see the shop and meet the guys. SO many pretty engines in there.

They are a PAIN IN THE *** to get out. They have 10mm hex heads and the threads start about 1-1/2" below the deck. On the first engine, I only broke one and was able to get it out with an overnight soak of PB and an EZ out but they are really hard to drill. The second engine, I managed to strip the head on one bolt (not a big deal) but broke three others on the same side.

Hopefully I can save this block for a spare but I still have the first one prepped so there's no setbacks.

EDIT - Got both heads off. This block still has a very clear crosshatch and zero ring ridge. If I can get the three bolts out I'll probably end up using this block. Ug... I have to do all that cleaning again.

There's an engine shop in town that opened up a few years ago. I finally had a chance to drop in today to see the shop and meet the guys. SO many pretty engines in there.

Last edited by kickerfox; 12-05-2013 at 05:39 PM.

#778

Registered

Thread Starter

Finally got the bottom end opened up. Looks great! 102k on this motor. All the bearings look good enough for another 100k. There's nothing on bearing to indicate .020 .040 etc. so I'm guessing they're originals. I'll try and cross the OEM part numbers. At least someone took care of this motor. As usual the oil rings are starting to stick but the pistons are perfect.

As for the boost... I'm going to have to go NA for now due to financial constraints. I blew my FIC money on the 2nd engine. Need to save up again. I'll try to build the exhaust manifolds in a way that makes them easy to modify. I could probably build them as turbo manifolds with the T25 flanges and then mock up temporary pipes until later. The intake will still be custom but it's probably going to hurt the performance until the turbos go on due to the short runner length.

Need to save up again. I'll try to build the exhaust manifolds in a way that makes them easy to modify. I could probably build them as turbo manifolds with the T25 flanges and then mock up temporary pipes until later. The intake will still be custom but it's probably going to hurt the performance until the turbos go on due to the short runner length.

I forget if I mentioned but with this engine I got the complete harness to the ECU. I have plenty of slack to hide most of it. I'm pretty confident this will all work but it's pretty unlikely the stability control will work. Fine by me.

As for the boost... I'm going to have to go NA for now due to financial constraints. I blew my FIC money on the 2nd engine.

Need to save up again. I'll try to build the exhaust manifolds in a way that makes them easy to modify. I could probably build them as turbo manifolds with the T25 flanges and then mock up temporary pipes until later. The intake will still be custom but it's probably going to hurt the performance until the turbos go on due to the short runner length.

Need to save up again. I'll try to build the exhaust manifolds in a way that makes them easy to modify. I could probably build them as turbo manifolds with the T25 flanges and then mock up temporary pipes until later. The intake will still be custom but it's probably going to hurt the performance until the turbos go on due to the short runner length.I forget if I mentioned but with this engine I got the complete harness to the ECU. I have plenty of slack to hide most of it. I'm pretty confident this will all work but it's pretty unlikely the stability control will work. Fine by me.

#779

Registered

Thread Starter

Intercooler is here  but it's pretty heavy.

but it's pretty heavy.

And... The shop is done polishing up the crank and getting out the broken headbolts. Said the crank spec'd perfect.

but it's pretty heavy.

but it's pretty heavy.

And... The shop is done polishing up the crank and getting out the broken headbolts. Said the crank spec'd perfect.

#780

Registered

Thread Starter

Well this sucks. The Isuzu MAF is one of those frequency output GM POS sensors. That means I'll need the FIC-8 which is $100s more then the FIC-6. Damn you GM! I mean... Damn you Isuzu for using GM stuff!

Want to hear what they sound like?

https://www.youtube.com/watch?v=qSqW...ature=youtu.be

Want to hear what they sound like?

https://www.youtube.com/watch?v=qSqW...ature=youtu.be

#781

Registered

Thread Starter

My 3" tubing is here, couplers, clamps, BOV and flange. Block was blasted, cleaned, honed, decked, and is ready to go. I started on the remote oil flanges. Have the CAD model done. CNC time.

I was in the middle of the Isuzu wiring harness when the gf stepped on our 8 month old 5lb Pomeranian and broke it's leg. $700 in vet bills. -uggg- Hopefully it sets ok and she won't need surgery to put a pin in.

There's a bit of interest over on the Isuzu forums for pistons for this engine. I got quoted $500 for custom forged pistons. I may have to consider it in my build.

I was in the middle of the Isuzu wiring harness when the gf stepped on our 8 month old 5lb Pomeranian and broke it's leg. $700 in vet bills. -uggg- Hopefully it sets ok and she won't need surgery to put a pin in.

There's a bit of interest over on the Isuzu forums for pistons for this engine. I got quoted $500 for custom forged pistons. I may have to consider it in my build.

Last edited by kickerfox; 12-19-2013 at 07:09 PM.

#783

Registered

Thread Starter

#785

Wow, the insults are flying, I think kickers knows a thing or two about engineering and hardening heat treatment. It's all about resources, not paying 2 or 3 middlemen for the same part.

#786

Even a set of Wossner pistons (below average quality) for a Miata costs around 500$, same goes for a set of Mahle ones.

You'd need 2 more for the isuzu, and they'd have to be custom designed for the application.. and they'd never mass produce them. Good luck with that.

You might be able to get a set for around that amount of money though, i simply wouldn't expect them to be "quality"\well designed pistons.

#787

Registered

Thread Starter

Forged pistons aren't made from exotic alloys. Typically a forged piston is just 4032 aluminum alloy which is common. The raw material is inexpensive. The expense of a forged part comes from the machining time involved for both the dies (used in the forging process) and final machining of the part. Those costs are usually diluted into the first run of parts. After that, the cost drops significantly (for the company having the parts made) but more times then not that price isn't passed on to the customer. Racing isn't cheap and $800-1600/set for pistons is a drop in the bucket compared to the rest of their build. They don't mind paying it.

For a new piston design, a set of 6 might cost $4000. So how does Wiseco, Supertech, Ross, etc. make custom pistons for $1000? Because they use raw forgings and machine them for what they need. A raw forging may be used for 20 different engines. Where do these forgings come from? The piston tree? Many of them come from China and are produced by, you guessed it, piston manufactures! So, if these companies already have the forgings and the machines, MAYBE you can gather that the cost would be less?

No he's right. I'm not a metallurgy chemistry and can't home brew my own alloys or calculate and computer model it's thermal expansion rates. I guess that makes me incapable of anything. That's why I leave it up to the manufacture to follow my specifications. That's why they exist after all.

Last edited by kickerfox; 12-20-2013 at 11:51 AM.

#788

Yes, and some Mahle pistons are made from 2618 aluminum alloy. Still kinda inexpensive but with different properties.

How would you shape the piston dome? how would you make the valve recesses? how tall would the piston be? How heavy\thick?

Please post the invoice of the manufacturer once you get your one-off pistons for that engine.

How would you shape the piston dome? how would you make the valve recesses? how tall would the piston be? How heavy\thick?

Please post the invoice of the manufacturer once you get your one-off pistons for that engine.

#789

Registered

Thread Starter

Yes, and some Mahle pistons are made from 2618 aluminum alloy. Still kinda inexpensive but with different properties.

How would you shape the piston dome? how would you make the valve recesses? how tall would the piston be? How heavy\thick?

Please post the invoice of the manufacturer once you get your one-off pistons for that engine.

How would you shape the piston dome? how would you make the valve recesses? how tall would the piston be? How heavy\thick?

Please post the invoice of the manufacturer once you get your one-off pistons for that engine.

Here's my thinking. 2 feet away from me are a set of pistons that came from a Rodeo with 102k. They look like new. The skirts look amassing. This tells me that whatever Honda engineers did with the design, it works well. The only overlook are the oil drain holes are too small or too few. They may be ok for Japan emissions but add a US emission system (and lazy American neglect) and they plug up. The design was later revised I think in '02. Ironically, another engine I like very much, the Suzuki H25A, has a similar issue where a chain tensioner getting plugged up resulting in severe engine damage. Interestingly the Suzuki H25A is used in the T51 Mustang (model P51) and the Isuzu 6VD1 is used in the Spitfire model. To me that speaks greatly of these engine because those are very respectable planes. $.02

For my needs, a replacement forged piston will, for the most part, follow the '98 OEM design. The dish and reliefs will copy the OEM piston and maintain the same 9:1 compression ratio. The pin off-set will remain at 1.5mm (need to verify). Compression height will be unchanged. Additional drain holes will be added. Rings will stay the same size but I may lower the bottom two in order to thicken the second ring land. Mass will wind up lighter due to the material. I haven't CAD modeled the OEM piston yet so I can't say 100% what I can or can't do.

I'm not building a top-fuel dragster. These pistons won't look much different then OEM. I only want to strengthen the weakest link. My goal is 450hp. If the cast pistons are at their limit at 450hp then I should replace them before the engine removes them for me. The next bottlenecks are the rods at 650hp. Or so I'm told. It makes sense to do the pistons for piece of mind.

Last edited by kickerfox; 12-20-2013 at 12:24 PM.

#790

It looks like you're one lucky sonuvabitch: Mahle makes some pistons!

http://www.mahle-aftermarket.com/C125790900540AC0/vwContentByUNID/377673464EBB37BCC12579AB0060C738/$FILE/PR-10-10.pdf

Talk to them, perhaps they could make a forged version out of their current lineup.

Some websites also show custom piston manufacturers. Some other forged pistons for the Acura 3.5l isuzu engine.

The problem is that almost every custom piston manufacturer either wants a 1500$ R\D Fee or a minimum order of 5\6 sets.

http://www.mahle-aftermarket.com/C125790900540AC0/vwContentByUNID/377673464EBB37BCC12579AB0060C738/$FILE/PR-10-10.pdf

Talk to them, perhaps they could make a forged version out of their current lineup.

Some websites also show custom piston manufacturers. Some other forged pistons for the Acura 3.5l isuzu engine.

The problem is that almost every custom piston manufacturer either wants a 1500$ R\D Fee or a minimum order of 5\6 sets.

#791

Registered

Thread Starter

Got a link? I have a friend building a 3.5L.

I don't know if that's lucky if their just cast. There's a TON of OEM parts available for the engine. Isuzu used it for so long in many countries in many different models. Fortunately, this drives down OEM replacement costs for most components like gaskets or the timing kit. Hell, even the heads are cheap but the engine block and that damn crankshaft are expensive.

There's very little aftermarket support. Hp Heaven in Australia builds them but it's not easy getting detailed info or prices out of them. I'm sure they have forged pistons in stock. They even make a forged crank for it but when I asked they said "We have billet crank, but the stock crank is good to at least 800hp @ wheels when prepped.".

Since Mahle produces both OEM and forged pistons I'll have to shoot them a call. At least they'll have the OEM specs on hand.

I don't know if that's lucky if their just cast. There's a TON of OEM parts available for the engine. Isuzu used it for so long in many countries in many different models. Fortunately, this drives down OEM replacement costs for most components like gaskets or the timing kit. Hell, even the heads are cheap but the engine block and that damn crankshaft are expensive.

There's very little aftermarket support. Hp Heaven in Australia builds them but it's not easy getting detailed info or prices out of them. I'm sure they have forged pistons in stock. They even make a forged crank for it but when I asked they said "We have billet crank, but the stock crank is good to at least 800hp @ wheels when prepped.".

Since Mahle produces both OEM and forged pistons I'll have to shoot them a call. At least they'll have the OEM specs on hand.

Last edited by kickerfox; 12-20-2013 at 01:22 PM.

#792

Registered

Thread Starter

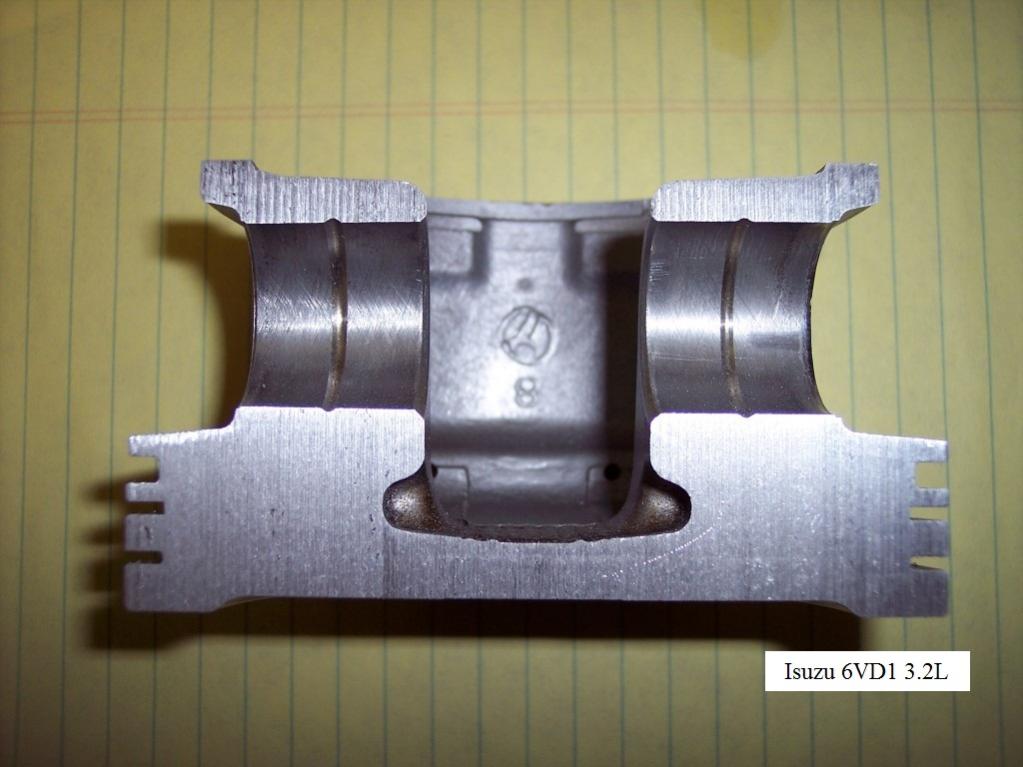

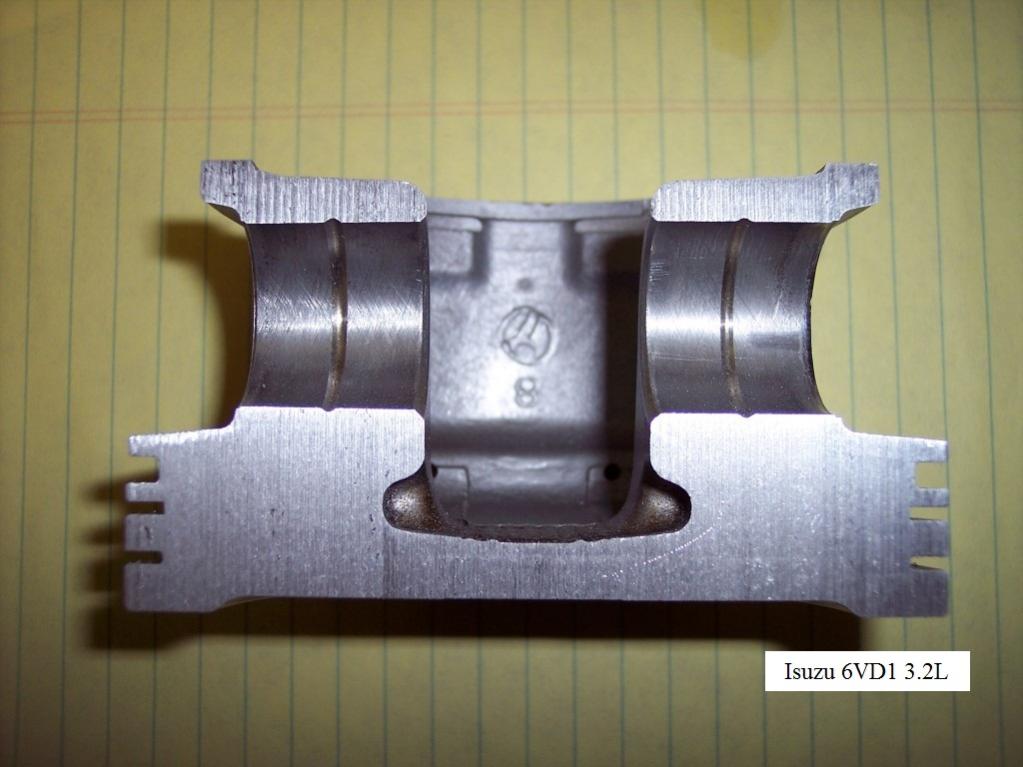

I just shoved a stock piston through the band saw to have a look. There's quite a bit of material up top which is good for absorbing heat and handling combustion pressures. Nice fat ring land on the top ring, much thinner on the second ring. Best not to get sloppy when setting the ring gaps. It can't be seen in this cross-section but looking into the bottom of the piston, the skirt is thicker near the pin and tapers down as it reaches the skirt sides of the piston. This is good for transferring heat into the skirts where it can be transferred to the cylinder wall.

I'm no piston expert but I do pay attention to details. I've see much worse designs then this. It's not exactly the lightest piston either so it's best to keep the revs in check.

I'm no piston expert but I do pay attention to details. I've see much worse designs then this. It's not exactly the lightest piston either so it's best to keep the revs in check.

#794

Registered

Thread Starter

Post 506 the engine was removed. It's been 8 months since then. Two engines purchased and torn down. One being rebuilt. LOTS has been done.

Hard to keep up reading this thread.

Hard to keep up reading this thread.

#795

So you're building a 3.2l? i looked at the 3.5l all this time.

By judging that piston we can see that this engine is built to last, not to work as a sports engine anyway. Have you considered shorter, bored pistons to increase the revs?

By judging that piston we can see that this engine is built to last, not to work as a sports engine anyway. Have you considered shorter, bored pistons to increase the revs?

#796

Registered

Thread Starter

I'm not sure what you mean by shorter piston. The compression height? And how do you bore a piston? Do you mean bore the cylinder to accept a larger piston?

The 3.2L and 3.5L both have 93.4mm bores. The 3.2L has a 77mm stroke. The 3.5L has an 85mm stroke. Different crankshafts. Both engines do use the same connecting rod which is also fairly long at 152mm. To account for the stroke, the 3.5L's piston pin was raised 4mm changing the compression height from ~33.7mm to ~29.7mm.

Back to the 3.2L. With a 93.4mm bore and 77mm stroke, the engine is decently oversquare. I would guess that it's RPM is limited by it's cam grind, valve springs, and crankshaft. What it does have is a very wide torque curve starting the moment you crack the throttle open. Not a good match for the RX8's 4.44 rear end.

Did you happen to catch that burnout video I posted of the black pickup bouncing off the rev limiter? I wonder what RPM he was at.

#797

Sorry, i meant to bore the cylinder and while shortening the piston's travel to help the engine rev higher and faster.

I just forgot that you wanted to turbo it. i don't think it's needed in that case.

I just forgot that you wanted to turbo it. i don't think it's needed in that case.

#800

Registered

Thread Starter

I've purchased a lot of the intercooler plumbing and some other turbo bits. Plus a pair of T25s are taunting me but it will likely start it's life being NA. Maybe mid-summer I can get to mounting the turbos. As with most projects it's the finances that delay them. I'm expanding my business so most of my income is being re-invested into that. I'd rather save a little and do everything right the first time which so far is coming along ok but the pace is a little slow.

Both the 3.2L and 3.5L are open deck with Siamesed cylinders. It's probably best not to remove material. There's typically little to be gained boring an engine unless it's an extreme NA build. The Isuzu 3.2L bore/stroke ratio is actually very good considering it's application. It has a 0.4mm larger bore and 1mm shorter stroke then the Honda C32B (NSX). It's already very close to being a sports car engine. If I could afford a haed job, cam grind, and forged crank I'd spin the hell out of it.

Both the 3.2L and 3.5L are open deck with Siamesed cylinders. It's probably best not to remove material. There's typically little to be gained boring an engine unless it's an extreme NA build. The Isuzu 3.2L bore/stroke ratio is actually very good considering it's application. It has a 0.4mm larger bore and 1mm shorter stroke then the Honda C32B (NSX). It's already very close to being a sports car engine. If I could afford a haed job, cam grind, and forged crank I'd spin the hell out of it.