Kickers V6 swap thread

#676

Registered

Thread Starter

That's an interesting idea. Has it been done before? What about it wiggling or vibrating?

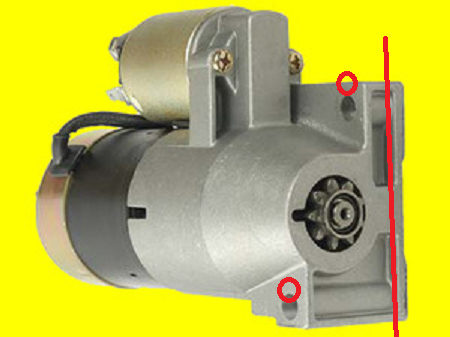

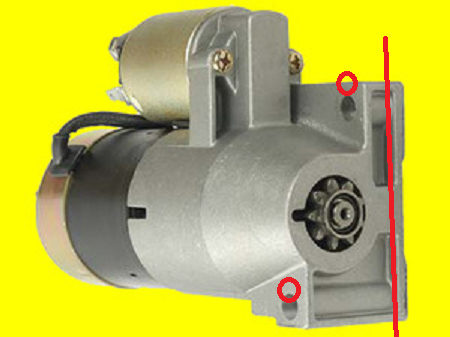

EDIT - I picked up the newer (smaller) 3.5L Isuzu starter today. If it can be modified to work with the 2.6L flywheel I'll stick with that. I'll have to see how far I can nudge it over by milling the mounting surface and relocating the holes. Both of the previous images were taken with the camera against the ac compressor to try to maintain scale. When I printed the images and held them to a light it looked like the 2.6L ring gear is very close to where it needed to be. That is strange though because laying one flywheel on the other on the floor it looked like the 2.6L flywheel was ~1/2" smaller.

EDIT - I picked up the newer (smaller) 3.5L Isuzu starter today. If it can be modified to work with the 2.6L flywheel I'll stick with that. I'll have to see how far I can nudge it over by milling the mounting surface and relocating the holes. Both of the previous images were taken with the camera against the ac compressor to try to maintain scale. When I printed the images and held them to a light it looked like the 2.6L ring gear is very close to where it needed to be. That is strange though because laying one flywheel on the other on the floor it looked like the 2.6L flywheel was ~1/2" smaller.

Last edited by kickerfox; 05-04-2013 at 01:38 PM.

#677

Registered

Join Date: Nov 2009

Location: Adriatic Paradise

Posts: 596

Likes: 0

Received 0 Likes

on

0 Posts

I did it on a boat I had many years ago, 340 mopar and ford toploader,used Loctite and torqued the bolts to spec,never had a problem. As parts are non existent here for what I'm doing, if I use a manual trans, I will do the same . The only light flywheel I can locate is $1000. AUD.

#678

Registered

Thread Starter

I have some work to do. The engine has a knock on #1. I heard it spinning the engine by hand (heads off) and on the down stroke I can hit the #1 piston with my hand and hear it clearly. Hard to judge but looks like about .010~.020" of play. The other 5 are ok. I'll drop the pan as soon as I get it on the stand and see how bad it is. Hopefully it didn't spin the bearing and the rod/crank are ok.

The oil was pretty thick, black, and low. Cylinders show signs of lack of oil (skirt wear) but no ring ridge and crosshatch is clear. A ball hone would quickly clean it up. One head bolt broke. Popped a cam journal and that looked ok. Combustion chamber and valves look nice and sooty so head gaskets and heads should be ok. If one was cylinder was clean I'd worry about cracks but these aren't known to have head or gasket failures.

That's the problem with these Isuzu engines. No one gives a **** about them. Those that do get 200,000+ out of them. Those that don't start burning oil at 75,000 and blame the engine. At least parts are cheap. The complete engine kit is under $400. Beats spending $3k+ on a reman and if I do it I'll know it's done right.

Since I'm in this engine anyways, I have the option of going with the lower compression pistons. Stock for this year was 9.8:1. I could probably get away with 10psi on that CR on pump gas and a good tune. Or... I find the older 9.1:1 (or 9.4?) pistons and shoot for 15psi but my off-boost torque and mileage may suffer slightly.

10psi should get me 350~375hp out of it. 0-60 calculates that to about 4 sec (2900lbs). If I can get my second gear just over 60mph it might actually do it. If I have to shift again to 3rd just for another 5mph that'll hurt my time. Granted these are all calculated figures but they're usually not that far off. After all, it's only physics.

The oil was pretty thick, black, and low. Cylinders show signs of lack of oil (skirt wear) but no ring ridge and crosshatch is clear. A ball hone would quickly clean it up. One head bolt broke. Popped a cam journal and that looked ok. Combustion chamber and valves look nice and sooty so head gaskets and heads should be ok. If one was cylinder was clean I'd worry about cracks but these aren't known to have head or gasket failures.

That's the problem with these Isuzu engines. No one gives a **** about them. Those that do get 200,000+ out of them. Those that don't start burning oil at 75,000 and blame the engine. At least parts are cheap. The complete engine kit is under $400. Beats spending $3k+ on a reman and if I do it I'll know it's done right.

Since I'm in this engine anyways, I have the option of going with the lower compression pistons. Stock for this year was 9.8:1. I could probably get away with 10psi on that CR on pump gas and a good tune. Or... I find the older 9.1:1 (or 9.4?) pistons and shoot for 15psi but my off-boost torque and mileage may suffer slightly.

10psi should get me 350~375hp out of it. 0-60 calculates that to about 4 sec (2900lbs). If I can get my second gear just over 60mph it might actually do it. If I have to shift again to 3rd just for another 5mph that'll hurt my time. Granted these are all calculated figures but they're usually not that far off. After all, it's only physics.

Last edited by kickerfox; 05-04-2013 at 11:43 PM.

#679

I love how you think its poor maintenance that causes the oil consumption on these engines. Do some reading. On the other hand congrats on the good work so far.

Your Isuzu owners with 200,000+ check the oil at every gas stop, and top it up frequently.

As for boost, I'm not sure where your getting 350 on 10psi, what method are you using, you clearly know the cfm changes between two different turbos at 10psi. Just another option, contact alpine they have supercharger systems available for this engine. Manifold, supercharger, etc.

Your Isuzu owners with 200,000+ check the oil at every gas stop, and top it up frequently.

As for boost, I'm not sure where your getting 350 on 10psi, what method are you using, you clearly know the cfm changes between two different turbos at 10psi. Just another option, contact alpine they have supercharger systems available for this engine. Manifold, supercharger, etc.

Last edited by ABdragonVX; 05-05-2013 at 06:37 AM.

#680

the rodeo i had didn't use/leak/magically disappear oil..... i maintained it like any other piston engined vehicle i have owned...

*(checked the oil about 1500miles into a oil change and changed it 3000-5000 miles....)

i have 3 co-workers that drive 2000-2004 rodeos with the v6... none have any problems with oil consumption etc... *(we are all mechanics for american airlines...)

could it possibly be the people with the issues either ran the living **** out of their vehicles without proper maintenance or just didn't maintain them untill they started having problems and blamed the manufacturer??

honda used the exact same motor in their suv without any real issues...

here is the consumer guide report for the rodeo.... nothing about oil consumption..

*(checked the oil about 1500miles into a oil change and changed it 3000-5000 miles....)

i have 3 co-workers that drive 2000-2004 rodeos with the v6... none have any problems with oil consumption etc... *(we are all mechanics for american airlines...)

could it possibly be the people with the issues either ran the living **** out of their vehicles without proper maintenance or just didn't maintain them untill they started having problems and blamed the manufacturer??

honda used the exact same motor in their suv without any real issues...

here is the consumer guide report for the rodeo.... nothing about oil consumption..

Trouble Spots

Consumer Guide's® Auto Editors have scoured repair bulletins and questioned mechanics to search for commonly occurring problems for a particular vehicle. In some cases we also give possible manufacturer suggested solutions. In many instances these trouble spots are Technical Service Bulletins posted by the manufacturer, however, we have our own expert looking at additional vehicle problems.

Doors: Unless the front-fender liners have been replaced, ice and snow can build up between the door and fender which caused door damage when it is opened. (1998)

Fuel gauge: The gas gauge may indicate full after a fill-up, then not move until the tank is half empty. (1998)

Rough idle: High/erratic idle on the 3.2-liter V6 may be due to one or more of the following: bad electrical ground, debris in power steering pressure switch, leaking manifold gasket. (1998-2000)

Steering problems: The steering wheel may shimmy or vibrate unless a steering-yoke spring kit is installed. (1998)

Transmission slippage: Delayed transmission engagement, after sitting overnight, may occur due to torque-converter draindown. (1998-99)

NHTSA RECALL HISTORY

1998 w/optional floormat: Repeated movement of feet can result in shifting of mat, which could interfere with gas pedal.

1998: Ground terminal was not properly crimped in engine-wiring harness, which will eventually cause stress fracture; could result in "no-start" or engine stalling.

1998-99: Paint was applied unevenly on rear axles of certain vehicles; could cause loosening of nut at lower-link bracket bolt.

1998-99: The rear-axle lower link may become separated from the rear axle.

1999: Vehicles fail to comply with federal requirement for "Occupant Protection in Interior Impact."

2000-01: Airbag inflators may contain too much generant. Exploding airbag module could cause severe injury.

2000-01: Airbag will not inflate properly due to the absence of a necessary component known as a check-valve pin.

2001: The fuel-return hose does not meet ozone-resistant specifications and could crack, causing fuel leakage.

2002-04: In five specified states, if fuel has been contaminated with silicon, small pinholes may develop in fuel pump feed port; leakage could lead to fire.

Consumer Guide's® Auto Editors have scoured repair bulletins and questioned mechanics to search for commonly occurring problems for a particular vehicle. In some cases we also give possible manufacturer suggested solutions. In many instances these trouble spots are Technical Service Bulletins posted by the manufacturer, however, we have our own expert looking at additional vehicle problems.

Doors: Unless the front-fender liners have been replaced, ice and snow can build up between the door and fender which caused door damage when it is opened. (1998)

Fuel gauge: The gas gauge may indicate full after a fill-up, then not move until the tank is half empty. (1998)

Rough idle: High/erratic idle on the 3.2-liter V6 may be due to one or more of the following: bad electrical ground, debris in power steering pressure switch, leaking manifold gasket. (1998-2000)

Steering problems: The steering wheel may shimmy or vibrate unless a steering-yoke spring kit is installed. (1998)

Transmission slippage: Delayed transmission engagement, after sitting overnight, may occur due to torque-converter draindown. (1998-99)

NHTSA RECALL HISTORY

1998 w/optional floormat: Repeated movement of feet can result in shifting of mat, which could interfere with gas pedal.

1998: Ground terminal was not properly crimped in engine-wiring harness, which will eventually cause stress fracture; could result in "no-start" or engine stalling.

1998-99: Paint was applied unevenly on rear axles of certain vehicles; could cause loosening of nut at lower-link bracket bolt.

1998-99: The rear-axle lower link may become separated from the rear axle.

1999: Vehicles fail to comply with federal requirement for "Occupant Protection in Interior Impact."

2000-01: Airbag inflators may contain too much generant. Exploding airbag module could cause severe injury.

2000-01: Airbag will not inflate properly due to the absence of a necessary component known as a check-valve pin.

2001: The fuel-return hose does not meet ozone-resistant specifications and could crack, causing fuel leakage.

2002-04: In five specified states, if fuel has been contaminated with silicon, small pinholes may develop in fuel pump feed port; leakage could lead to fire.

#681

Registered

Thread Starter

No it doesn't. It may be correct to say the CFM changes between two engines.

10psi of manifold pressure is 10psi of manifold pressure. It doesn't matter how your making it. The RPM of the engine will then determines the "CFM" being consumed. If the turbo is making more air then the engine consumes you have a leak. It's measured in lb/min not CFM by the way.

It's measured in lb/min not CFM by the way.

What does vary from turbo to turbo is the temperature of the charge air, exhaust restriction, and lag.

Atmospheric pressure is 14.7psi. So you can think about it as 14.7psi is on the engine making 215hp. Remember that's 14.7psi at the throttle body not manifold pressure so it's actually less. The first thing a turbo would do is get that 14.7psi in the manifold. If the turbo then adds another 14.7psi, the engine would produce 430hp. Probably a bit more.

Ever wonder how the heck a 1.3L rotary engine spools turbos as big as they do? Because the engine pumps 1.3L twice compared to it's piston counterpart. It's really 2.6L by comparison.

This isn't rocket science. Stop treating it that way. No wonder things may see so hard to believe. Must be lack of understanding.

10psi of manifold pressure is 10psi of manifold pressure. It doesn't matter how your making it. The RPM of the engine will then determines the "CFM" being consumed. If the turbo is making more air then the engine consumes you have a leak.

It's measured in lb/min not CFM by the way.

It's measured in lb/min not CFM by the way.What does vary from turbo to turbo is the temperature of the charge air, exhaust restriction, and lag.

Atmospheric pressure is 14.7psi. So you can think about it as 14.7psi is on the engine making 215hp. Remember that's 14.7psi at the throttle body not manifold pressure so it's actually less. The first thing a turbo would do is get that 14.7psi in the manifold. If the turbo then adds another 14.7psi, the engine would produce 430hp. Probably a bit more.

Ever wonder how the heck a 1.3L rotary engine spools turbos as big as they do? Because the engine pumps 1.3L twice compared to it's piston counterpart. It's really 2.6L by comparison.

This isn't rocket science. Stop treating it that way. No wonder things may see so hard to believe. Must be lack of understanding.

#683

Registered

Thread Starter

I'm going to speak in PSIA and PSIG terms. Make note where they are used.

Compared to space (0 PSIA) there is 14.7 PSIA on earth. 14.7 PSIA is 1 BAR. When the piston moves down (in an NA engine) there's 14.7 PSIA of air outside the cylinder trying to fill the space. Lets assume 100% volumetric efficiency. At BDC the pressure in the cylinder is equal to atmospheric.

Ok so far?

Now lets double that pressure in the cylinder to 29.4 PSIA. This means the turbo is placing 14.7 PSIG in the cylinder. If 14.7 PSIA makes 215hp, 29.4 PSIA makes 430hp. There are many other variables involved but this is a rough guestimate on translating boost to horsepower on any given engine (in my case it's 3.2L). Put in twice the air/fuel, make twice the power. If I stuff 6.4L of air into it I'll make the power of a 6.4L NA engine.

Other variables are things like intake ports and exhaust. Is the pressure in the manifold completely filling the cylinder? no. There is always some loss. Next is exhaust. Can all that extra volume of combustion get out? Don't forget there's a turbo in the way as well.

As far as CFM. In order to maintain the pressure, the CFM will need to increase as RPM increases. All ABdragonVX did was add a time variable into the equation. This is when you have to hit the turbo chart and see if your turbo will provide the lb/min of airflow required to maintain the boost level you want at the RPM you want. Math Math Math. For a given power output, the "CFM" requirement of the engine doesn't change. The turbo has no effect on this other then meeting that requirement.

Compared to space (0 PSIA) there is 14.7 PSIA on earth. 14.7 PSIA is 1 BAR. When the piston moves down (in an NA engine) there's 14.7 PSIA of air outside the cylinder trying to fill the space. Lets assume 100% volumetric efficiency. At BDC the pressure in the cylinder is equal to atmospheric.

Ok so far?

Now lets double that pressure in the cylinder to 29.4 PSIA. This means the turbo is placing 14.7 PSIG in the cylinder. If 14.7 PSIA makes 215hp, 29.4 PSIA makes 430hp. There are many other variables involved but this is a rough guestimate on translating boost to horsepower on any given engine (in my case it's 3.2L). Put in twice the air/fuel, make twice the power. If I stuff 6.4L of air into it I'll make the power of a 6.4L NA engine.

Other variables are things like intake ports and exhaust. Is the pressure in the manifold completely filling the cylinder? no. There is always some loss. Next is exhaust. Can all that extra volume of combustion get out? Don't forget there's a turbo in the way as well.

As far as CFM. In order to maintain the pressure, the CFM will need to increase as RPM increases. All ABdragonVX did was add a time variable into the equation. This is when you have to hit the turbo chart and see if your turbo will provide the lb/min of airflow required to maintain the boost level you want at the RPM you want. Math Math Math. For a given power output, the "CFM" requirement of the engine doesn't change. The turbo has no effect on this other then meeting that requirement.

Last edited by kickerfox; 05-05-2013 at 01:06 PM.

#685

Registered

Thread Starter

I got the bottom end open. The crank and rod survived! The bearing was worn to the copper but it didn't spin. This crankshaft looks a lot beefier then I imagined. Same goes for the rods. I'm pretty sure the rods are forged. They do have oil squirters. There are number markings in this engine and the pistons look awfully clean for 120,000 miles. I'm guessing this may have been a remanufactured engine. The rings aren't fully broke in yet. 0.o This rod shows some heat on the big end. I'll have to check it's roundness.

Check out that rod. Isuzu on left, 1.8L Miata on right. Don't ask how I turned it into a banana.

Last edited by kickerfox; 05-05-2013 at 02:57 PM.

#689

Registered

Thread Starter

I spoke too soon. The thrust bearing is toast. It's going to need a crank. The guy who sold me the engine is going to see what he can do about it. The block, pistons and rods are all in great shape. For what I paid for the engine I'm not too worried about it. It'll wind up costing me $1000 but it'll be rebuilt and painted. It'll look and run like a brand new engine when I'm through with it.

This crank rings like a forged crank when tapped but I read it's cast. If it's steel I'll just have it repaired.

Last edited by kickerfox; 05-05-2013 at 10:01 PM.

#690

pack the opening of the thrust bearing with bearing grease... turn down a wooden dowel/turn a piece of bar stock in a lathe till it will enter the opening... drive it in... the grease will force the thrust bearing out and replace... *(at least thats how it used to be done....)

#691

Registered

Thread Starter

pack the opening of the thrust bearing with bearing grease... turn down a wooden dowel/turn a piece of bar stock in a lathe till it will enter the opening... drive it in... the grease will force the thrust bearing out and replace... *(at least thats how it used to be done....)

#693

Honestly I prefer single turbos, less plumbing and easier to setup. The right single on this v6 should have little to no lag anyway, I love the diesel turbos just because they are designed to spool fast and live a long life. On the flip side I ran a t25 on the talon with no boost control for 3 months, that little thing would not give up, eventually the head blew though lol good thing it was just a junkyard project.

Don't take this the wrong way but your better off having this engine rebuilt, it should be a blast once your done though. Be careful if your doing it yourself, ill do a quick search but there was a bolt somewhere that is super finicky, it can and will shear off if your not careful

Don't take this the wrong way but your better off having this engine rebuilt, it should be a blast once your done though. Be careful if your doing it yourself, ill do a quick search but there was a bolt somewhere that is super finicky, it can and will shear off if your not careful

#694

Registered

iTrader: (3)

No it doesn't. It may be correct to say the CFM changes between two engines.

10psi of manifold pressure is 10psi of manifold pressure. It doesn't matter how your making it. The RPM of the engine will then determines the "CFM" being consumed. If the turbo is making more air then the engine consumes you have a leak. It's measured in lb/min not CFM by the way.

It's measured in lb/min not CFM by the way.

What does vary from turbo to turbo is the temperature of the charge air, exhaust restriction, and lag.

Atmospheric pressure is 14.7psi.

10psi of manifold pressure is 10psi of manifold pressure. It doesn't matter how your making it. The RPM of the engine will then determines the "CFM" being consumed. If the turbo is making more air then the engine consumes you have a leak.

It's measured in lb/min not CFM by the way.

It's measured in lb/min not CFM by the way.What does vary from turbo to turbo is the temperature of the charge air, exhaust restriction, and lag.

Atmospheric pressure is 14.7psi.

It's the confusion between CFM and SCFM. Wish we could all use an actual mass flow rate. I tried explaining how you could use smaller piping for your charge pipe once and got called an idiot several times for my effort.

Nice explanation though. Also liked the one on PSIA vs PSIG. BTW some Isuzu engines have nice ion sensing systems, work well with water injection and the like. Glad to see you're sticking with it, hope to see more actual progress.

#695

I think that you are posting much of this information on the wrong forum! I can totally understand why rotor guys are annoyed with this project, it is like doing thread on how install a Honda motor into DSM on one of the DSM forums  .

.

But here you are and I am very interested in your project! Unlike you, I am STUCK with this engine and trying to find ANY information on how to modify it. To give you a point of reference, I took my '01 Vehicross w/167k miles to a dragstrip this past weekend, it ran consistent 17.0's @ 80mph, I also got a chance to weigh it: 4025lbs by itself (4245lbs with me in it).

Unlike you, I am STUCK with this engine and trying to find ANY information on how to modify it. To give you a point of reference, I took my '01 Vehicross w/167k miles to a dragstrip this past weekend, it ran consistent 17.0's @ 80mph, I also got a chance to weigh it: 4025lbs by itself (4245lbs with me in it).

Having raced DSM's for 20+ years, I am somewhat familiar with turbos, so I am considering doing "rear turbo" set-up for the VX.

You might have mentioned this earlier, but what is the most boost people been able to run on this engine (in stock and modified form)? Have you found any good engine management options?

Thanks!

.

.But here you are and I am very interested in your project!

Unlike you, I am STUCK with this engine and trying to find ANY information on how to modify it. To give you a point of reference, I took my '01 Vehicross w/167k miles to a dragstrip this past weekend, it ran consistent 17.0's @ 80mph, I also got a chance to weigh it: 4025lbs by itself (4245lbs with me in it).

Unlike you, I am STUCK with this engine and trying to find ANY information on how to modify it. To give you a point of reference, I took my '01 Vehicross w/167k miles to a dragstrip this past weekend, it ran consistent 17.0's @ 80mph, I also got a chance to weigh it: 4025lbs by itself (4245lbs with me in it). Having raced DSM's for 20+ years, I am somewhat familiar with turbos, so I am considering doing "rear turbo" set-up for the VX.

You might have mentioned this earlier, but what is the most boost people been able to run on this engine (in stock and modified form)? Have you found any good engine management options?

Thanks!

#696

Registered

Thread Starter

AEM's FIC piggy-backed on the stock OBD2 ECU is the closest thing your going to find to an OBD2 standalone. It has the ability to re-map the MAF using it's internal MAP sensor, if you need MAF elimination, and also has a fuel injector calculator to help with your base map when using larger then stock injectors.

#697

Registered

iTrader: (3)

Wasn't this thread. Sorry I meant "you" as "someone" not directly you.  If you calculate the actual velocity through the tubing it allows for fairly small charge pipes. Preturbo intake should be as unrestricted as possible though, it doesn't get and VE increase from resonance (no pulses) and it is limited to 14.7psia (atmo) at the suction side.

If you calculate the actual velocity through the tubing it allows for fairly small charge pipes. Preturbo intake should be as unrestricted as possible though, it doesn't get and VE increase from resonance (no pulses) and it is limited to 14.7psia (atmo) at the suction side.

If you calculate the actual velocity through the tubing it allows for fairly small charge pipes. Preturbo intake should be as unrestricted as possible though, it doesn't get and VE increase from resonance (no pulses) and it is limited to 14.7psia (atmo) at the suction side.

If you calculate the actual velocity through the tubing it allows for fairly small charge pipes. Preturbo intake should be as unrestricted as possible though, it doesn't get and VE increase from resonance (no pulses) and it is limited to 14.7psia (atmo) at the suction side.

#698

Registered

Thread Starter

In the case of my 3.2L (195ci) with a 7000RPM redline.

350hp@7.7PSIG 38.5lb/min (480 CFM).

385hp@10PSIG is 42.5lb/min (525CFM)

This assumes a .95 VE. Looks like I could get away with 2". I'd use a 2.5" FMIC and 2.5" up to the throttle body. The sudden drop in pressure at the intercooler has a cooling effect.

I found the information below on another forum.

"The velocities are in miles per hour and mach, and the flow rates are in cfm. Measurements for the piping are in inches."

*.4 Mach is the point at which air becomes turbulent and losses in efficiency start to occur exponentially. The key is to stay under that speed. You want to use the smallest piping possible that still flows enough to meet your needs. Larger than necessary piping increases lag time with no measurable gain

2" piping

1.57 x 2 = 3.14 sq in

300 cfm = 156 mph = 0.20 mach

400 cfm = 208 mph = 0.27 mach

500 cfm = 261 mph = 0.34 mach

585 cfm max = 304 mph = 0.40 mach

2.25" piping

3.9740625 sq in = 1.98703125 x 2

300 cfm = 123 mph = 0.16 mach

400 cfm = 164 mph = 0.21 mach

500 cfm = 205 mph = 0.26 mach

600 cfm = 247 mph = 0.32 mach

700 cfm = 288 mph = 0.37 mach

740 cfm max = 304 mph = 0.40 mach

2.5" piping

4.90625 sq in = 2.453125 x 2

300 cfm = 100 mph = 0.13 mach

400 cfm = 133 mph = 0.17 mach

500 cfm = 166 mph = 0.21 mach

600 cfm = 200 mph = 0.26 mach

700 cfm = 233 mph = 0.30 mach

800 cfm = 266 mph = 0.34 mach

900 cfm = 300 mph = 0.39 mach

913 cfm max = 304 mph = 0.40 mach

2.75" piping

5.9365625 sq in = 2.96828125 x 2

300 cfm = 82 mph = 0.10 mach

400 cfm = 110 mph = 0.14 mach

500 cfm = 137 mph = 0.17 mach

600 cfm = 165 mph = 0.21 mach

700 cfm = 192 mph = 0.25 mach

800 cfm = 220 mph = 0.28 mach

900 cfm = 248 mph = 0.32 mach

1000 cfm = 275 mph = 0.36 mach

1100 cfm max = 303 mph = 0.40 mach

350hp@7.7PSIG 38.5lb/min (480 CFM).

385hp@10PSIG is 42.5lb/min (525CFM)

This assumes a .95 VE. Looks like I could get away with 2". I'd use a 2.5" FMIC and 2.5" up to the throttle body. The sudden drop in pressure at the intercooler has a cooling effect.

I found the information below on another forum.

"The velocities are in miles per hour and mach, and the flow rates are in cfm. Measurements for the piping are in inches."

*.4 Mach is the point at which air becomes turbulent and losses in efficiency start to occur exponentially. The key is to stay under that speed. You want to use the smallest piping possible that still flows enough to meet your needs. Larger than necessary piping increases lag time with no measurable gain

2" piping

1.57 x 2 = 3.14 sq in

300 cfm = 156 mph = 0.20 mach

400 cfm = 208 mph = 0.27 mach

500 cfm = 261 mph = 0.34 mach

585 cfm max = 304 mph = 0.40 mach

2.25" piping

3.9740625 sq in = 1.98703125 x 2

300 cfm = 123 mph = 0.16 mach

400 cfm = 164 mph = 0.21 mach

500 cfm = 205 mph = 0.26 mach

600 cfm = 247 mph = 0.32 mach

700 cfm = 288 mph = 0.37 mach

740 cfm max = 304 mph = 0.40 mach

2.5" piping

4.90625 sq in = 2.453125 x 2

300 cfm = 100 mph = 0.13 mach

400 cfm = 133 mph = 0.17 mach

500 cfm = 166 mph = 0.21 mach

600 cfm = 200 mph = 0.26 mach

700 cfm = 233 mph = 0.30 mach

800 cfm = 266 mph = 0.34 mach

900 cfm = 300 mph = 0.39 mach

913 cfm max = 304 mph = 0.40 mach

2.75" piping

5.9365625 sq in = 2.96828125 x 2

300 cfm = 82 mph = 0.10 mach

400 cfm = 110 mph = 0.14 mach

500 cfm = 137 mph = 0.17 mach

600 cfm = 165 mph = 0.21 mach

700 cfm = 192 mph = 0.25 mach

800 cfm = 220 mph = 0.28 mach

900 cfm = 248 mph = 0.32 mach

1000 cfm = 275 mph = 0.36 mach

1100 cfm max = 303 mph = 0.40 mach

Last edited by kickerfox; 05-06-2013 at 01:18 PM.

#699

Registered

iTrader: (3)

Yup. 2" is still my plan, although I've been a bit detoured in my build. Funny how charge piping size is more related to engine displacement than anything else. The actual lbm/hr or SCFM doesn't matter that much, it's the actual volumetric flow of the engine that matters.

If you double the pressure (at the same CFM) the resistance in the charge pipe goes up very slightly. Ain't physics grand.

If you double the pressure (at the same CFM) the resistance in the charge pipe goes up very slightly. Ain't physics grand.

#700

in my experience the IC pipe routing is important too, if you have straight pipe runs, they can be pretty small, but if you have some bends, or a lot of bends, bigger is better.

its easy to test, you put a boost gauge on both sides of IC/said pipe and see the pressure drop.

i'd measure the turbo outlet and then pick the next size up as a start...

its easy to test, you put a boost gauge on both sides of IC/said pipe and see the pressure drop.

i'd measure the turbo outlet and then pick the next size up as a start...