Quantitative Coolant Flow Simulation

#77

Team... I like you.

I honestly do not believe that what's being seen here is the S2 impeller taking cues from the Mazmart impeller. Look at it this way, both the Mazmart and S2 impellers were an attempt at improving flaws of the S1 impeller. The Mazmart impeller did this by creating smoother transitions and longer distances/times to accelerate the fluid to a given speed. The S2 impeller did this by creating smoother transitions, removing as much of the central shaft from the flow as possible (adding flow efficiency), and jerking (accelerating the fluid's rate of acceleration) as it reaches the outside of the impeller by making the outside tips more like those of a straight vaned impeller than the inside tips.

They both fullfill the purpose that they were designed for. The Mazmart impeller's goal was to drastically reduce cavitation, something that it did quite successfully even with it's apparent flaws. The S2 impeller's goal was likely to reduce cavitation while not making a drastic difference in flow (which it may or may not have done, we can't tell until it gets tested).

They both fullfill the purpose that they were designed for. The Mazmart impeller's goal was to drastically reduce cavitation, something that it did quite successfully even with it's apparent flaws. The S2 impeller's goal was likely to reduce cavitation while not making a drastic difference in flow (which it may or may not have done, we can't tell until it gets tested).

#80

Moder8

iTrader: (1)

After the track...

No, the remedy pump did not make me taller, grow more hair or add inches. : (

If you go back a few posts, the problem I am trying to solve is high RPM temp spikes, that, based on this data, look an awful lot like cavitation. I was aborting runs in 85 degree weather while watching the temp go from the 190s to 210+ rather rapidly. I would abort at over 210. I had this problem at Roebling and Sebring. This data is from a track weekend at Roebling.

We had a cold day day, a warm morning, and a warmer afternoon. In Florida language, warm afternoon, after 38 freaking degrees camping the night before, is about 70, with full sun and hotter track temps. Not real scientific, but, hey, it was my day off..

Towing the trailer up to Savannah, from Orlando, I saw 185 the entire way. The polar vortex had not hit, so it was still warm. This is not real difference from before, the thermostat is governing everything. But, the flow was sufficient to keep things cool with the remedy, pulling a trailer (700 or so pounds, maybe more) at 70 mph.

First day, freaking cold, track temps in the high 180s. This is looking good. Rode with daughter (does not shift, runs 8500 all the way up the hill, around 9, and down the straight, never saw 190. This is promising too. We are also driving the car back to back. But, it is cold out.

Second day, polar vortex is gone, short sleeve shirt weather. I got it up to 190 running the **** out of it. I am not even sure the thermostat is all the way open here. If it were, I would have expected more temp fluctuations. I do have thermostat test notes someplace, just not sure where. Someone chime if you have them for an OEM thermostat. And, it stayed there pretty much 190 all the way around the track. If it had been 10 degrees warmer, I would not expect 10 degree higher water temps. This is really good news, and points strongly to cavitation being the issue. And indicates a Remedy as something to defeat cavitation, while still providing flow.

I consider this problem solved. If I get back someplace really hot, and get more data, I will update this post. But, we ran the **** out of the car, it ran for 4+ hours a day, and never got hot. When I opened the hood after runs, it was not hot.

Now, option 2 is to underdrive the factory pump. From the data, you still have flow, but it will still cavitate unless you really change the speed something like 25%. And, the pulleys are not cheap either. The only benefit is to underdrive the AC a tad and reduce cycling, but I live in Florida. I need lots of AC. That may be an option for more northern folks.

Further tests will likely have to wait. I think I burned through my Rivals. They lasted a year (8 event weekends, all but one at Roebling). Also had a really neat failure on my sons car, resulting in him getting the tire budget and me standing down to preserve spousal relations.

Green

No, the remedy pump did not make me taller, grow more hair or add inches. : (

If you go back a few posts, the problem I am trying to solve is high RPM temp spikes, that, based on this data, look an awful lot like cavitation. I was aborting runs in 85 degree weather while watching the temp go from the 190s to 210+ rather rapidly. I would abort at over 210. I had this problem at Roebling and Sebring. This data is from a track weekend at Roebling.

We had a cold day day, a warm morning, and a warmer afternoon. In Florida language, warm afternoon, after 38 freaking degrees camping the night before, is about 70, with full sun and hotter track temps. Not real scientific, but, hey, it was my day off..

Towing the trailer up to Savannah, from Orlando, I saw 185 the entire way. The polar vortex had not hit, so it was still warm. This is not real difference from before, the thermostat is governing everything. But, the flow was sufficient to keep things cool with the remedy, pulling a trailer (700 or so pounds, maybe more) at 70 mph.

First day, freaking cold, track temps in the high 180s. This is looking good. Rode with daughter (does not shift, runs 8500 all the way up the hill, around 9, and down the straight, never saw 190. This is promising too. We are also driving the car back to back. But, it is cold out.

Second day, polar vortex is gone, short sleeve shirt weather. I got it up to 190 running the **** out of it. I am not even sure the thermostat is all the way open here. If it were, I would have expected more temp fluctuations. I do have thermostat test notes someplace, just not sure where. Someone chime if you have them for an OEM thermostat. And, it stayed there pretty much 190 all the way around the track. If it had been 10 degrees warmer, I would not expect 10 degree higher water temps. This is really good news, and points strongly to cavitation being the issue. And indicates a Remedy as something to defeat cavitation, while still providing flow.

I consider this problem solved. If I get back someplace really hot, and get more data, I will update this post. But, we ran the **** out of the car, it ran for 4+ hours a day, and never got hot. When I opened the hood after runs, it was not hot.

Now, option 2 is to underdrive the factory pump. From the data, you still have flow, but it will still cavitate unless you really change the speed something like 25%. And, the pulleys are not cheap either. The only benefit is to underdrive the AC a tad and reduce cycling, but I live in Florida. I need lots of AC. That may be an option for more northern folks.

Further tests will likely have to wait. I think I burned through my Rivals. They lasted a year (8 event weekends, all but one at Roebling). Also had a really neat failure on my sons car, resulting in him getting the tire budget and me standing down to preserve spousal relations.

Green

The following users liked this post:

DocWalt (03-18-2021)

#81

threadsurrection!

just wondering how much the stock and remedy flow at idle/lowish rpm...

there a a couple new electric pump kits for RX-7's with max flow at 40 Gal/m I just want to compare

also, any updates? more simulations?

just wondering how much the stock and remedy flow at idle/lowish rpm...

there a a couple new electric pump kits for RX-7's with max flow at 40 Gal/m I just want to compare

also, any updates? more simulations?

#83

Evening fellow rotary enthusiasts!

As a recap, this data has been gathered in an effort to model, simulate, and compare the differences in flow between the stock Rx8 water pump and the Remedy Water pump sold by Mazmart! The software used to model the flow through the housing and the impeller was Autodesk Inventor Professional 2015. The computational fluid dynamics package used to simulate the transient flow was Autodesk Simulation CFD 2015.

Each simulation was done under a specific pair of boundary conditions being: 88kPa static pressure (the pressure allowed by a functioning radiator cap), and a temperature of 84.44 degrees Celsius (the target coolant temperature of the stock thermostat). The fluid flow was made of a simulated material that is (in all measurable properties distilled water in order to create a standard. Cavitation is less likely in the majority of coolants due to their higher viscosities.

Cavitation data is not directly available from the simulation, however the amount of cavitation is represented by the combined rate and magnitude of the oscillations in rotating power. This is due to vapor bubble regions forming (water molecules being ripped apart from one another, using a significant amount of power), and the same bubble regions imploding (rapidly decreasing the volume in front of the proceeding blade, sucking it forward with great force).

Here is a brief analysis of some of the results, there is more data available but this is all that is in a presentable/understandable format right now. Oddly, I'm not allowed to upload Excel documents on this forum, so if you really want the summary data then shoot me a pm and I can email it to you.

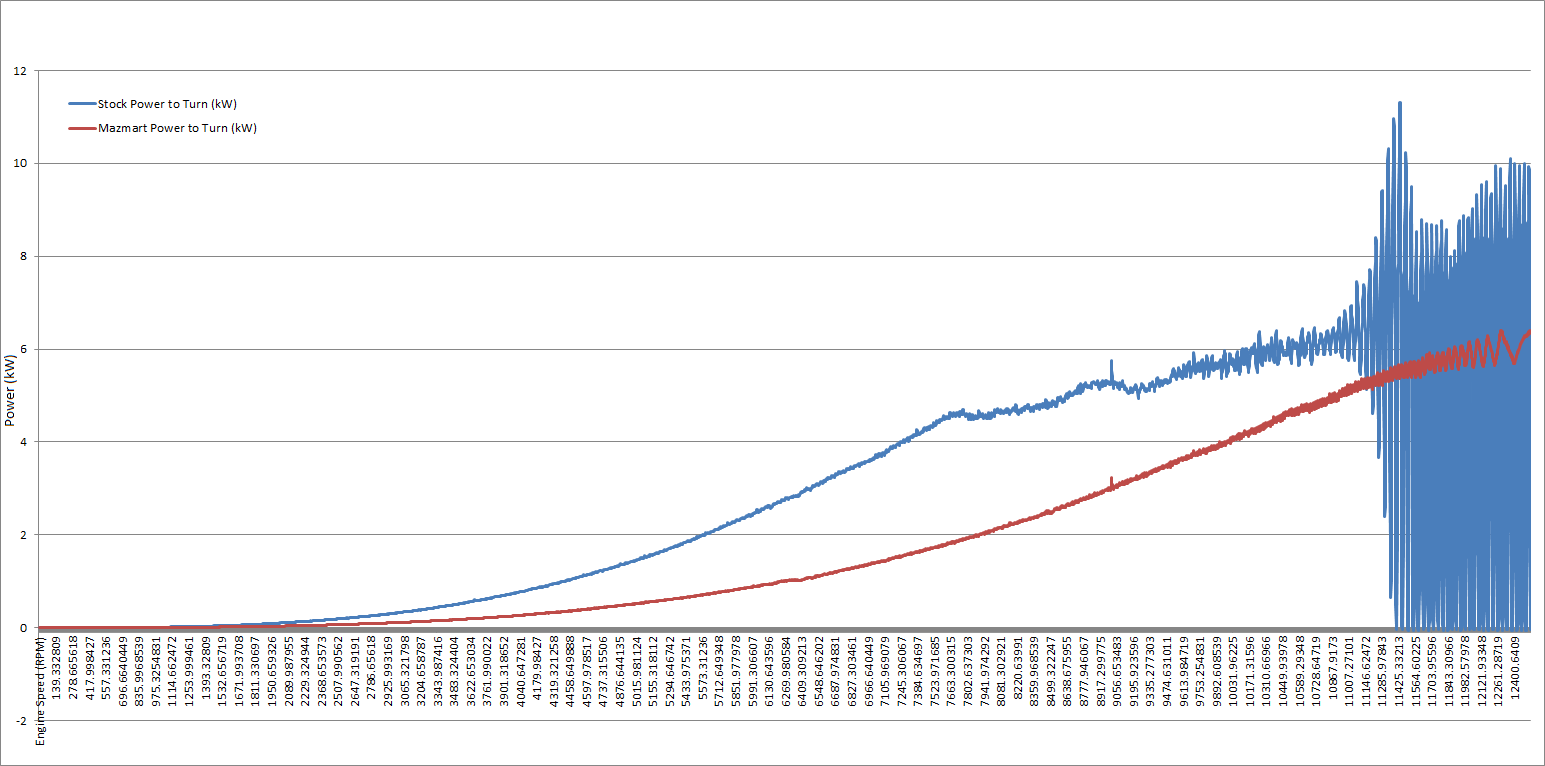

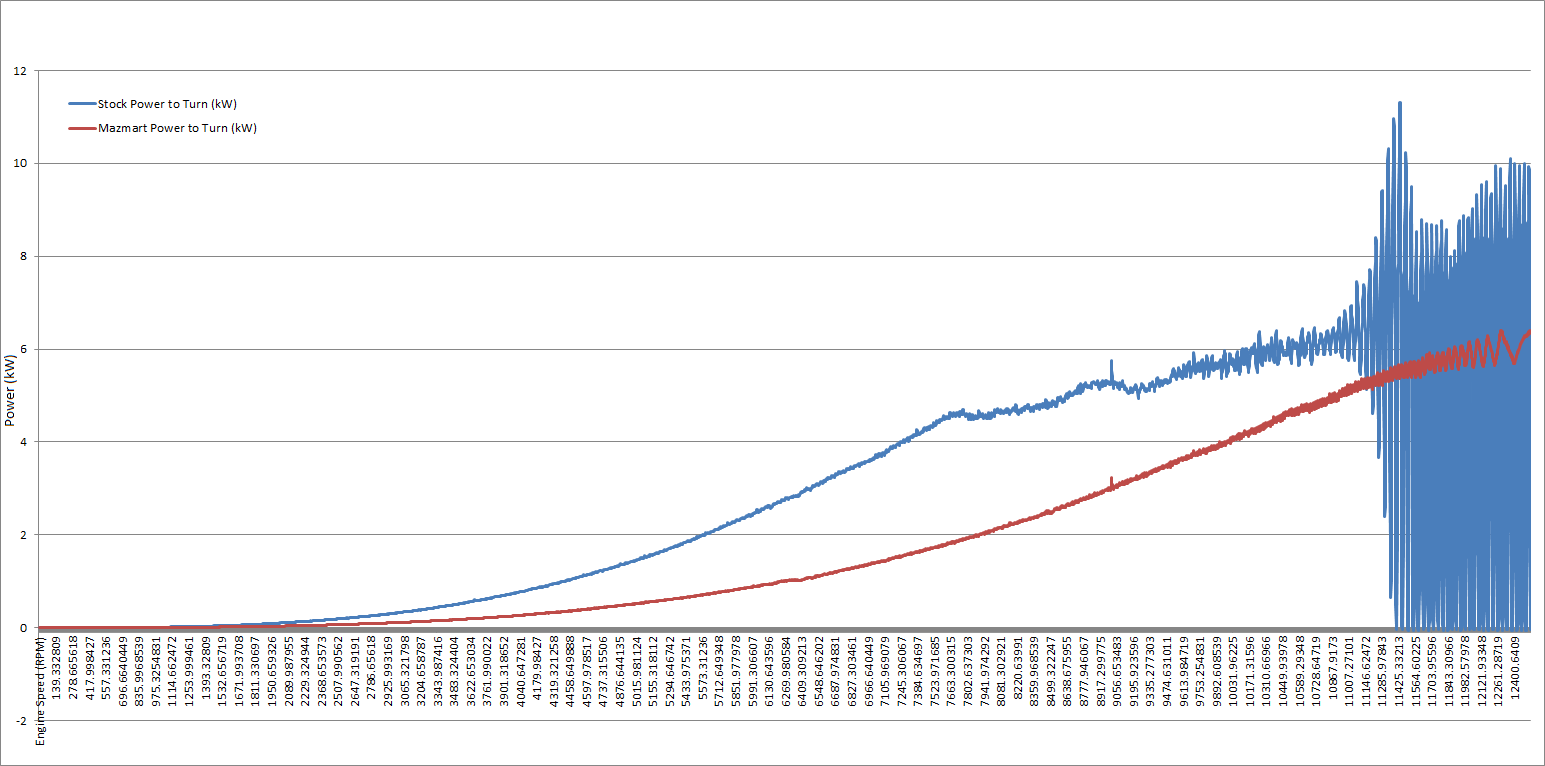

First up is Power vs Engine RPM!

As you can see from the graph of the stock impeller (blue), there are two main points where cavitation begins, that is at 7735 RPM and 9300 RPM. From 7700 RPM to 9300 RPM there is a serious drop in the transmission of power from the impeller to the flow, suggesting a primary cavitation. A secondary, much more violent cavitation occurs at 9300 RPM and freaking skyrockets from there. Note that the average power would be linearly increasing after 9300 RPM

The graph of the Mazmart impeller shows a significantly lower power usage, and a much more controlled cavitation event.

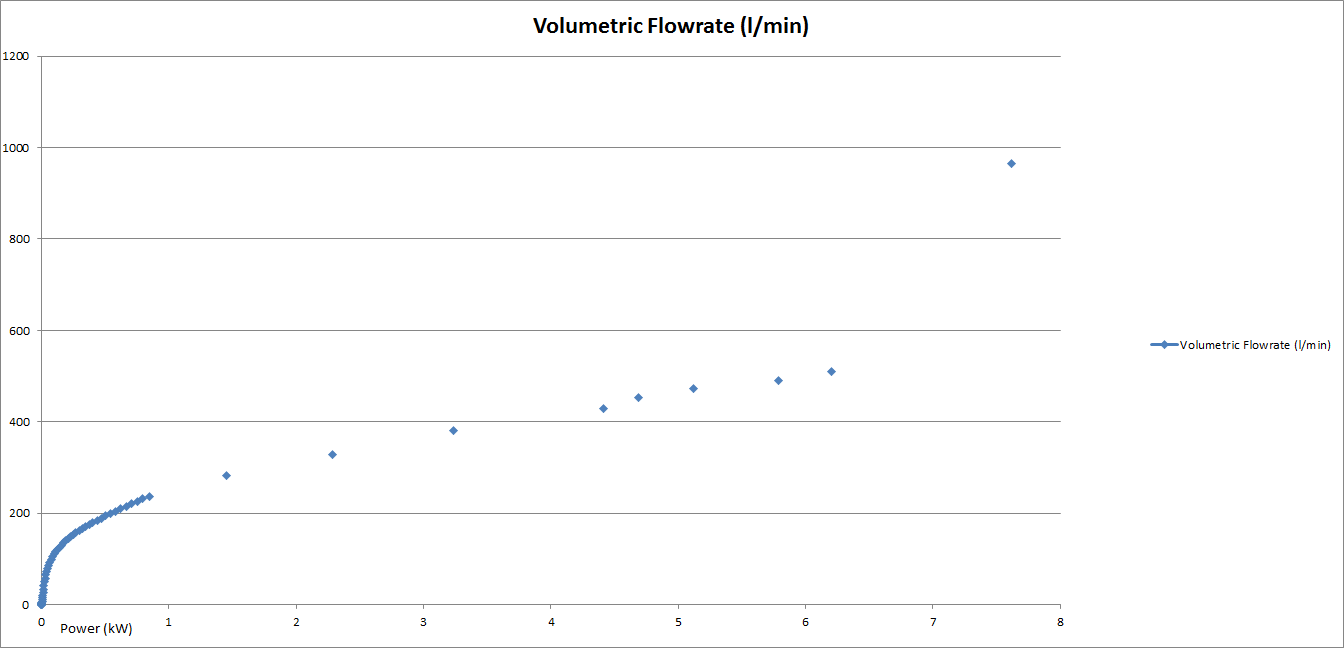

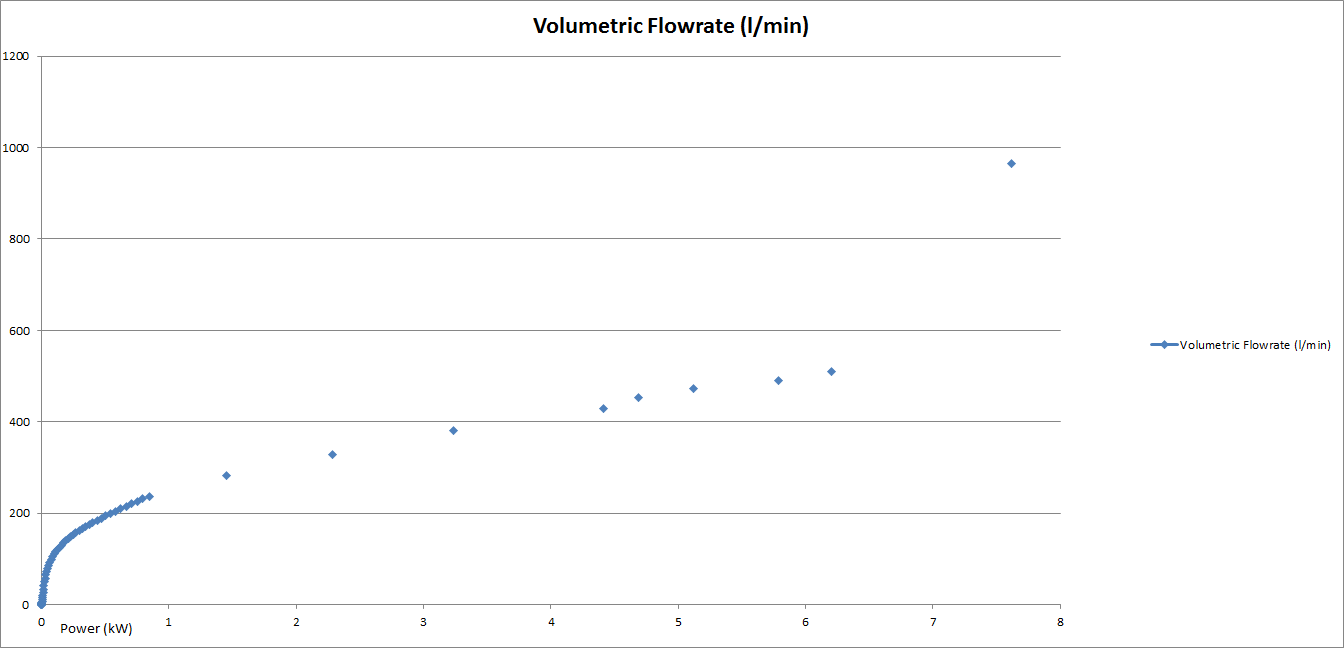

Next is Flowrate vs Engine RPM (the one everyone cares about)

The data for this portion was tricky, and excel refused to interpolate or make a best fit curve, but this is it. The outlying point at 11700 Engine RPM is some sort of significant change in the vapor bubble region, but should be ignored when analyzing flow.

At 9300 RPM (stock redline), the Stock Impeller is capable of flowing 490 l/min (130 G/min).

At 9300 RPM, the Mazmart Impeller is capable of flowing 345 l/min (91 G/min).

These last two should really be transposed, but excel was giving me issues so I just let it be.

Stock Flow Rate vs Power

Mazmart Flow Rate vs Power

As we've already seen, the Mazmart impeller has a much more consistent power usage, along with significantly less power consumption. For both impellers as flow increases power usage increases exponentially (as expected).

Animation of the cavitation volume fraction of the Stock Pump

Mazda RX-8 Stock Water Pump Simulation - YouTube

Mazmart Pump

Mazda RX-8 Mazmart Impeller Pump Simulation - YouTube

The stock redline of 9300 Engine RPM occurs around step 225/300 (shown in the bottom left corner). Each step in the animation is ~150 RPM increase at the impeller or a ~125 RPM increase at the ES.

Now for some provocative facts and notes.

These two simulations were run as accurately as possible, however they are aimed at the max capabilities of the pump itself. It would be very nearly impossible to determine the exact flow rate through the entire coolant system (well, it's possible, but it would take months of simulations). Fortunately coolant systems are designed to flow as much as reasonably possible, which means that the flow data is likely within a +15% margin of error.

The Mazmart impeller flows less than the stock impeller under all conditions. However the efficiency of the stock impeller is less beyond 11000 RPM.

The Stock impeller cavitates more than the mazmart impeller from 7300 RPM onwards.

The curves along the blades on the mazmart impeller are quote simply eccentric circles, offset 60 degrees, the same diameter as the impeller (suggesting that someone with literally no impeller design knowledge made it).

The full disk type lower disk of the mazmart impeller is designed in such a way that the pressure differential on either side will decrease bearing life (not significantly, just a note on poor design choices)

The smoothed edges and gentle of the mazmart impeller are a major contributing factor to it's great cavitation performance at higher RPMs.

Above 11000 RPM, the cavitation of the stock pump would likely cause visible damage to the water pump housing/bearings over time.

As a recap, this data has been gathered in an effort to model, simulate, and compare the differences in flow between the stock Rx8 water pump and the Remedy Water pump sold by Mazmart! The software used to model the flow through the housing and the impeller was Autodesk Inventor Professional 2015. The computational fluid dynamics package used to simulate the transient flow was Autodesk Simulation CFD 2015.

Each simulation was done under a specific pair of boundary conditions being: 88kPa static pressure (the pressure allowed by a functioning radiator cap), and a temperature of 84.44 degrees Celsius (the target coolant temperature of the stock thermostat). The fluid flow was made of a simulated material that is (in all measurable properties distilled water in order to create a standard. Cavitation is less likely in the majority of coolants due to their higher viscosities.

Cavitation data is not directly available from the simulation, however the amount of cavitation is represented by the combined rate and magnitude of the oscillations in rotating power. This is due to vapor bubble regions forming (water molecules being ripped apart from one another, using a significant amount of power), and the same bubble regions imploding (rapidly decreasing the volume in front of the proceeding blade, sucking it forward with great force).

Here is a brief analysis of some of the results, there is more data available but this is all that is in a presentable/understandable format right now. Oddly, I'm not allowed to upload Excel documents on this forum, so if you really want the summary data then shoot me a pm and I can email it to you.

First up is Power vs Engine RPM!

As you can see from the graph of the stock impeller (blue), there are two main points where cavitation begins, that is at 7735 RPM and 9300 RPM. From 7700 RPM to 9300 RPM there is a serious drop in the transmission of power from the impeller to the flow, suggesting a primary cavitation. A secondary, much more violent cavitation occurs at 9300 RPM and freaking skyrockets from there. Note that the average power would be linearly increasing after 9300 RPM

The graph of the Mazmart impeller shows a significantly lower power usage, and a much more controlled cavitation event.

Next is Flowrate vs Engine RPM (the one everyone cares about)

The data for this portion was tricky, and excel refused to interpolate or make a best fit curve, but this is it. The outlying point at 11700 Engine RPM is some sort of significant change in the vapor bubble region, but should be ignored when analyzing flow.

At 9300 RPM (stock redline), the Stock Impeller is capable of flowing 490 l/min (130 G/min).

At 9300 RPM, the Mazmart Impeller is capable of flowing 345 l/min (91 G/min).

These last two should really be transposed, but excel was giving me issues so I just let it be.

Stock Flow Rate vs Power

Mazmart Flow Rate vs Power

As we've already seen, the Mazmart impeller has a much more consistent power usage, along with significantly less power consumption. For both impellers as flow increases power usage increases exponentially (as expected).

Animation of the cavitation volume fraction of the Stock Pump

Mazda RX-8 Stock Water Pump Simulation - YouTube

Mazmart Pump

Mazda RX-8 Mazmart Impeller Pump Simulation - YouTube

The stock redline of 9300 Engine RPM occurs around step 225/300 (shown in the bottom left corner). Each step in the animation is ~150 RPM increase at the impeller or a ~125 RPM increase at the ES.

Now for some provocative facts and notes.

These two simulations were run as accurately as possible, however they are aimed at the max capabilities of the pump itself. It would be very nearly impossible to determine the exact flow rate through the entire coolant system (well, it's possible, but it would take months of simulations). Fortunately coolant systems are designed to flow as much as reasonably possible, which means that the flow data is likely within a +15% margin of error.

The Mazmart impeller flows less than the stock impeller under all conditions. However the efficiency of the stock impeller is less beyond 11000 RPM.

The Stock impeller cavitates more than the mazmart impeller from 7300 RPM onwards.

The curves along the blades on the mazmart impeller are quote simply eccentric circles, offset 60 degrees, the same diameter as the impeller (suggesting that someone with literally no impeller design knowledge made it).

The full disk type lower disk of the mazmart impeller is designed in such a way that the pressure differential on either side will decrease bearing life (not significantly, just a note on poor design choices)

The smoothed edges and gentle of the mazmart impeller are a major contributing factor to it's great cavitation performance at higher RPMs.

Above 11000 RPM, the cavitation of the stock pump would likely cause visible damage to the water pump housing/bearings over time.

Thanks!

Thread

Thread Starter

Forum

Replies

Last Post