16X Engine – Possible Technology Applications

#28

Registered

Not sure why you would limit the 16x to gasoline if your goal is fuel economy. Mazda's already put out a hydrogen model rx8 and I can't believe that they aren't considering alternate fuel source applications for the 16x if they're looking at a 2011 model timeline.

If they can push out an engine that can run on gas or hydrogen with decent power and as great of a ride and look of the current 8 then they've got something unique on the market. That'll sell a lot more of them then a good FI 16x that allows the 8 to just fit in the current niche. It's also the current emphasis at Ford which has to be looking at leveraging the technology unique to Mazda in the auto world. The infrastructure may or may not be in place in time for the car but if it's capable of handling multiple fuel sources it can make it to the market before the infrastructure is set.

Just my $.02.

If they can push out an engine that can run on gas or hydrogen with decent power and as great of a ride and look of the current 8 then they've got something unique on the market. That'll sell a lot more of them then a good FI 16x that allows the 8 to just fit in the current niche. It's also the current emphasis at Ford which has to be looking at leveraging the technology unique to Mazda in the auto world. The infrastructure may or may not be in place in time for the car but if it's capable of handling multiple fuel sources it can make it to the market before the infrastructure is set.

Just my $.02.

1. It's made from Propane.

2. It makes MORE power than gasoline.

3. It is not a new fuel, it has been used for many years.

4. It's Nitro-freaking-Methane!

#29

Registered

The thermal efficiency of the N/A rotary has been shown to be roughly in the 26-28% range. Back in 1992, NASA did a study on improving the BSFC for the rotary engine. They managed to achieve a thermal efficiency of 37% (BSFC .375 lb/hp hr) with the use of a turbocharger, meaning that the potential is there for BSFC improvements.

BTW, where did you get your 26-28% thermal efficiency number?

#30

Registered

#31

Registered

Join Date: Oct 2008

Location: Montreal,QC

Posts: 2,256

Likes: 0

Received 0 Likes

on

0 Posts

It would be crazy if Mazda could develop a system that could shut off one rotor for cruising and when you really need the "power" it would activate both rotors. You know, kind of how like those hemi engines can use 4 cylinders for cruising to save gas and stuff.

But Im guessing it would be a lonnnng way before that ever happens.

But Im guessing it would be a lonnnng way before that ever happens.

#32

there's an old thread in the forum that discusses that but goes into a more intrincate and viable technique of skipping combustion events alternating between faces of both rotors to help keep the torque fluctuations to a minimum.

just shutting down one rotor is not that beneficial as it creates torque imbalance, friction drag and pumping losses from the non-working rotor.

just shutting down one rotor is not that beneficial as it creates torque imbalance, friction drag and pumping losses from the non-working rotor.

#33

Registered

Join Date: Oct 2008

Location: Montreal,QC

Posts: 2,256

Likes: 0

Received 0 Likes

on

0 Posts

there's an old thread in the forum that discusses that but goes into a more intrincate and viable technique of skipping combustion events alternating between faces of both rotors to help keep the torque fluctuations to a minimum.

just shutting down one rotor is not that beneficial as it creates torque imbalance, friction drag and pumping losses from the non-working rotor.

just shutting down one rotor is not that beneficial as it creates torque imbalance, friction drag and pumping losses from the non-working rotor.

#34

Momentum Keeps Me Going

[embed]<object width="340" height="285"><param name="movie" value="http://www.youtube.com/v/Gr8nOeHOkNY&hl=en&fs=1&color1=0x5d1719&color2=0xcd 311b&border=1"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/Gr8nOeHOkNY&hl=en&fs=1&color1=0x5d1719&color2=0xcd 311b&border=1" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="340" height="285"></embed></object>[/embed]

[embed]<object width="340" height="285"><param name="movie" value="http://www.youtube.com/v/6BCgl2uumlI&hl=en&fs=1&color1=0x5d1719&color2=0xcd 311b&border=1"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/6BCgl2uumlI&hl=en&fs=1&color1=0x5d1719&color2=0xcd 311b&border=1" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="340" height="285"></embed></object>[/embed]

Last edited by Spin9k; 03-18-2009 at 05:22 PM.

#35

Registered

Join Date: Jan 2005

Location: Palmdale, CA

Posts: 210

Likes: 0

Received 0 Likes

on

0 Posts

Yeah there really isn't anything that can be physically shut down on a rotary, but what about skipping combustion cycles? Each rotor has three faces, so what if it skips 1/3 of the combustions when the engine is cruising? Or maybe 1/6? That might be able to provide a 10-20% increase in highway fuel economy, unless I'm missing something (which I admit is very possible  .

.

.

.

#36

Registered

Yeah there really isn't anything that can be physically shut down on a rotary, but what about skipping combustion cycles? Each rotor has three faces, so what if it skips 1/3 of the combustions when the engine is cruising? Or maybe 1/6? That might be able to provide a 10-20% increase in highway fuel economy, unless I'm missing something (which I admit is very possible  .

.

.

.Last edited by robrecht; 03-21-2009 at 06:25 AM.

#38

Super Moderator

I know this is an Oldish Thread...

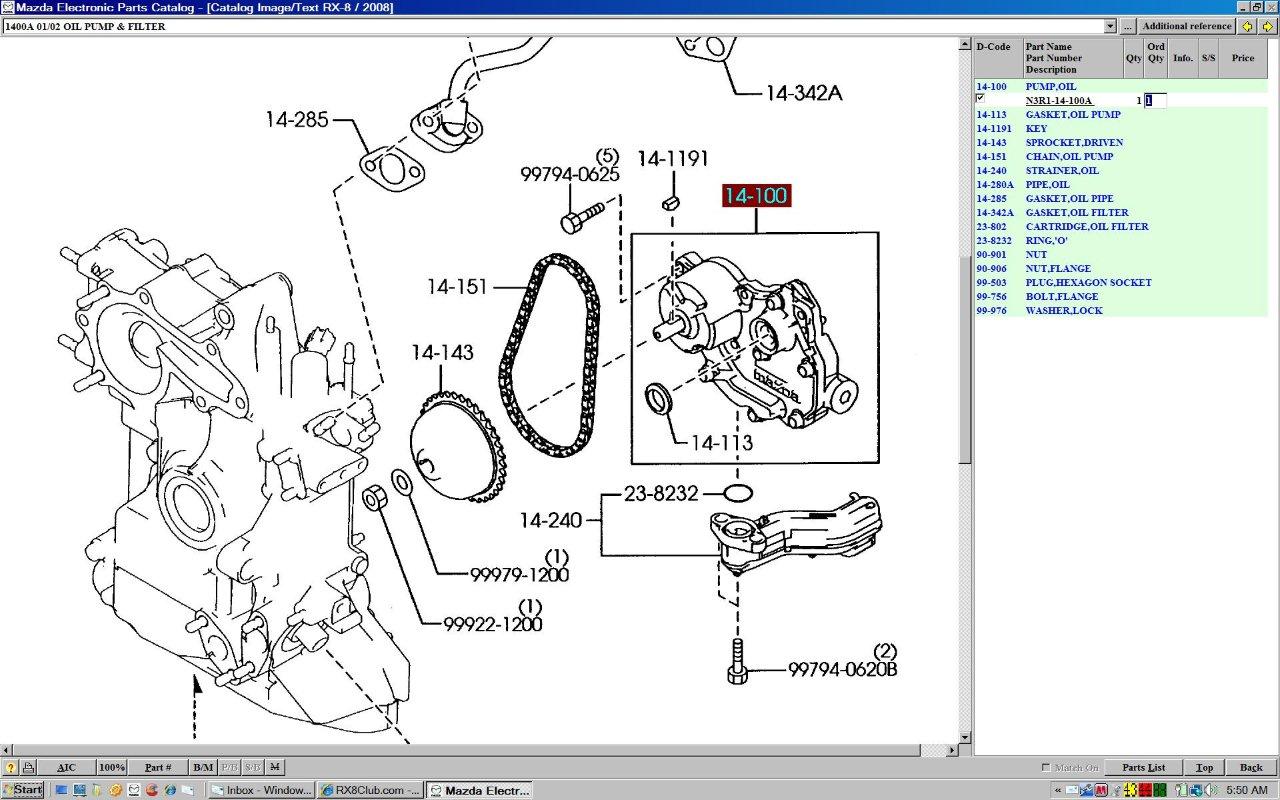

Many of the features shown on the new 16X have been incorporated in the latest Series II (09) RX-8 13B RENESIS.

The new EMOP (Electric Metering Oil Pumps (2))

The additional Leading (middle) Oil Injector for each rotor housing lubricating the centre of Apex Seals.

The new location and larger Oil Filter.

The new High Pressure Oil Pump, there is no longer the separate Oil Pressure Regulator with Plunger and Spring fitted to the bottom of iron housing.

Many of the features shown on the new 16X have been incorporated in the latest Series II (09) RX-8 13B RENESIS.

The new EMOP (Electric Metering Oil Pumps (2))

The additional Leading (middle) Oil Injector for each rotor housing lubricating the centre of Apex Seals.

The new location and larger Oil Filter.

The new High Pressure Oil Pump, there is no longer the separate Oil Pressure Regulator with Plunger and Spring fitted to the bottom of iron housing.

#39

Ayrton Senna Forever

I know this is an Oldish Thread...

Many of the features shown on the new 16X have been incorporated in the latest Series II (09) RX-8 13B RENESIS.

The new EMOP (Electric Metering Oil Pumps (2))

The additional Leading (middle) Oil Injector for each rotor housing lubricating the centre of Apex Seals.

The new location and larger Oil Filter.

The new High Pressure Oil Pump, there is no longer the separate Oil Pressure Regulator with Plunger and Spring fitted to the bottom of iron housing.

Many of the features shown on the new 16X have been incorporated in the latest Series II (09) RX-8 13B RENESIS.

The new EMOP (Electric Metering Oil Pumps (2))

The additional Leading (middle) Oil Injector for each rotor housing lubricating the centre of Apex Seals.

The new location and larger Oil Filter.

The new High Pressure Oil Pump, there is no longer the separate Oil Pressure Regulator with Plunger and Spring fitted to the bottom of iron housing.

It would be very strange, and cool!!!

According to the european web tech page of the RENESIS II.:

Oil discharge pressure (reference value)

-212°F, 1,500 rpm, 40.6 PSI

-212 F, 3,000 rpm, 72.5 PSI

Relief valve opening pressure (reference value) 156.6 PSI

#42

Super Moderator

Does it mean that the oil pressure would reach 156,6 PSI in the engine?

It would be very strange, and cool!!!

According to the european web tech page of the RENESIS II.:

Oil discharge pressure (reference value)

-212°F, 1,500 rpm, 40.6 PSI

-212 F, 3,000 rpm, 72.5 PSI

Relief valve opening pressure (reference value) 156.6 PSI

It would be very strange, and cool!!!

According to the european web tech page of the RENESIS II.:

Oil discharge pressure (reference value)

-212°F, 1,500 rpm, 40.6 PSI

-212 F, 3,000 rpm, 72.5 PSI

Relief valve opening pressure (reference value) 156.6 PSI

I can not find any oil pressure relief valve as a separate unit.

We know there is a new Oil Pump assy set up, I am assuming it is incorporated in the somewhat Large body.

#43

Ayrton Senna Forever

Maybe in the REN II. they left away this bypass valve. Is it possible 156,6 PSi oil pressure in an engine?

#45

Super Moderator

As I said the S2 RENESIS no longer has this separate Valve...well I can not find one...all I can find is an oil pressure SWITCH located on one of the EMOP's which obviously monitors (makes sure) there is oil pressure/oil available for the two EMOP's use.

#46

Super Moderator

Keep in mine the Series II RENESIS is Identical (from what I can configure) to the new 16X in technologies...two EMOP's and the extra Oil Injector for each rotor housing...

Other differences are in the new 16X...

1. Larger cc Capacity....Larger "Diameter" Rotors and Internal Dimensions not a wide as the 13B (Rotors and their Housings).

2. DI (Direct Injection)

3. Aluminum Side Housings (with Iron facing inserts of about 2mm...making engine lighter).

That is about all I can see and think of..

Other differences are in the new 16X...

1. Larger cc Capacity....Larger "Diameter" Rotors and Internal Dimensions not a wide as the 13B (Rotors and their Housings).

2. DI (Direct Injection)

3. Aluminum Side Housings (with Iron facing inserts of about 2mm...making engine lighter).

That is about all I can see and think of..

#47

Certified Mazda Tech

the new motors have higher pressures due to a new oil pump IIRC, id have to go thru the tech docs again.

As for running 156 psi oil pressure, i doubt it, the spec is in the FSM ill double check it later, time for bed.

kevin.

As for running 156 psi oil pressure, i doubt it, the spec is in the FSM ill double check it later, time for bed.

kevin.

#48

Ayrton Senna Forever

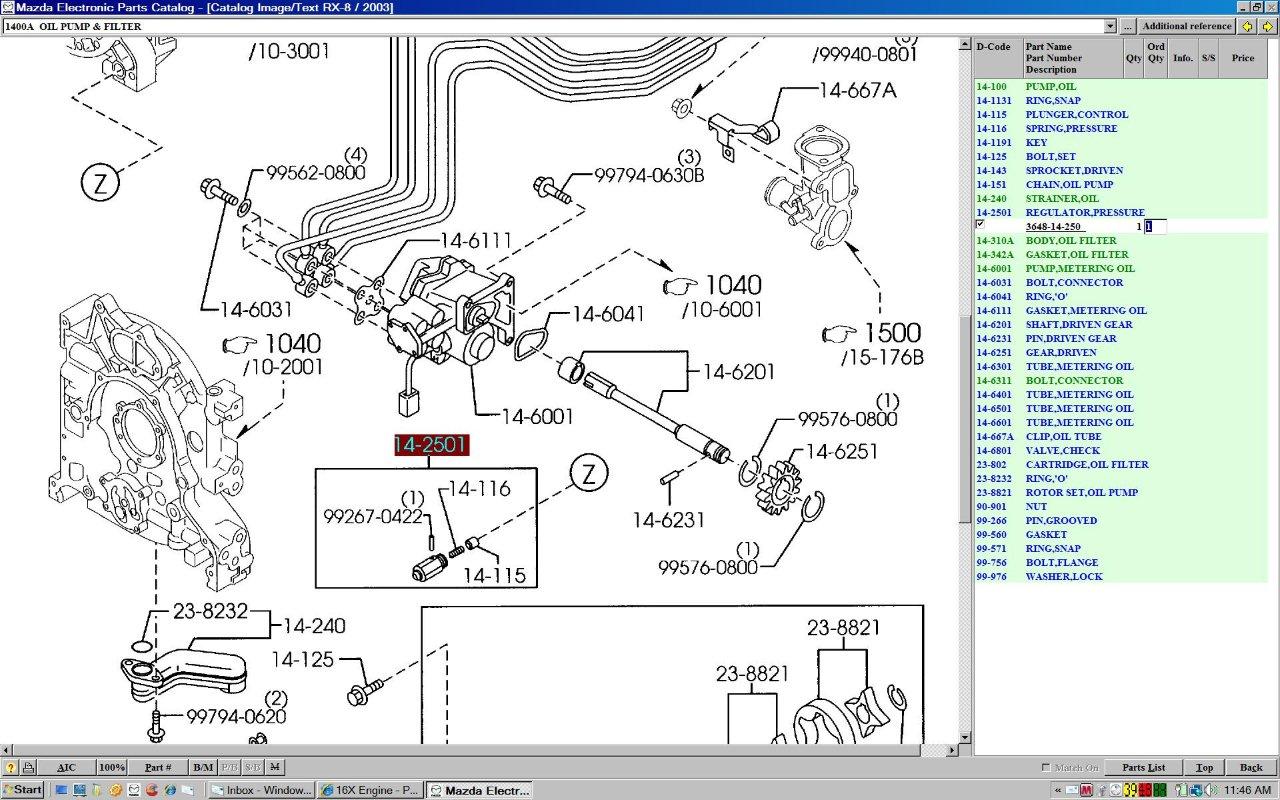

This is the Oil Pressure Regulator (3648-14-250) Shown here on the 2003 S1 RENESIS which screws into the bottom internal Rear Iron Housing like ALL other previous Rotaries..

As I said the S2 RENESIS no longer has this separate Valve...well I can not find one...all I can find is an oil pressure SWITCH located on one of the EMOP's which obviously monitors (makes sure) there is oil pressure/oil available for the two EMOP's use.

As I said the S2 RENESIS no longer has this separate Valve...well I can not find one...all I can find is an oil pressure SWITCH located on one of the EMOP's which obviously monitors (makes sure) there is oil pressure/oil available for the two EMOP's use.

Now in the S2 Renesis the reference min. oil pressure is 72 PSi at 3000rpm. It much higher than the S1's same data. So they would not use the 78-92 PSI regulator in this high temp and rpm rotary engine. This regulator valve (bypass) would open too early, at very low rpms if they use it in the new S2 engine.

According to this, if our informations are true there is only the 156,6 PSI regulator valve in the S2 engine, no other pressure maximiser valve. This allowed high maximum pressure means absolute protection for the engine (cooling, bearing), but sounds strange.

#49

Super Moderator

aryton012

Well, here is some trivia for you the 3648-14-250 was last used in the FC before that 1976 RX-4 13B..that is the parts model code 3648 for 76 RX-4.

The internal plunger and spring (0221-14-115 and 0221-14-116) are the exact same parts used in ALL oil pumps in Mazda's since 1967-08, Mazda 1500,1600,626,929..Rotary.

With a spring change (0324-14-116) for their smaller engines Mazda 2,3.

We know the S1 as had a lot of Rotor Bearing issues (Chomped out), I have always thought it was the oil grade..still do., So Mazda have increased oil pressure flows to improve cooling and bearing life as you said.

I have some concern about the oil control rings and o rings, whether they will stand up OK as they has been NO Internal parts changes in the S2 when compared to S1 (Rotors,seals etc).

Well, here is some trivia for you the 3648-14-250 was last used in the FC before that 1976 RX-4 13B..that is the parts model code 3648 for 76 RX-4.

The internal plunger and spring (0221-14-115 and 0221-14-116) are the exact same parts used in ALL oil pumps in Mazda's since 1967-08, Mazda 1500,1600,626,929..Rotary.

With a spring change (0324-14-116) for their smaller engines Mazda 2,3.

We know the S1 as had a lot of Rotor Bearing issues (Chomped out), I have always thought it was the oil grade..still do., So Mazda have increased oil pressure flows to improve cooling and bearing life as you said.

I have some concern about the oil control rings and o rings, whether they will stand up OK as they has been NO Internal parts changes in the S2 when compared to S1 (Rotors,seals etc).

#50

Ayrton Senna Forever

aryton012

Well, here is some trivia for you the 3648-14-250 was last used in the FC before that 1976 RX-4 13B..that is the parts model code 3648 for 76 RX-4.

The internal plunger and spring (0221-14-115 and 0221-14-116) are the exact same parts used in ALL oil pumps in Mazda's since 1967-08, Mazda 1500,1600,626,929..Rotary.

With a spring change (0324-14-116) for their smaller engines Mazda 2,3.

Well, here is some trivia for you the 3648-14-250 was last used in the FC before that 1976 RX-4 13B..that is the parts model code 3648 for 76 RX-4.

The internal plunger and spring (0221-14-115 and 0221-14-116) are the exact same parts used in ALL oil pumps in Mazda's since 1967-08, Mazda 1500,1600,626,929..Rotary.

With a spring change (0324-14-116) for their smaller engines Mazda 2,3.

**** fiber optics, lets go bio optics!

**** fiber optics, lets go bio optics!