Building Custom Turbo for the RX-8

#77

I know you didn't use weld-els, sorry for my confusing wording.

So you welded layer 2 directly to layer 1? Or you 'built' layer 2 piece by piece around layer one, so that they don't come in contact?

Just try to visualize the method...in the final result do layer 1 and layer 2 touch each other? Or are they separated?

So you welded layer 2 directly to layer 1? Or you 'built' layer 2 piece by piece around layer one, so that they don't come in contact?

Just try to visualize the method...in the final result do layer 1 and layer 2 touch each other? Or are they separated?

#79

0 Psi for comfirmation of no leaks then 3 PSI for testing and verification of drivability.

After everything shakes out, 7 PSI or so depending on fueling.

Once I am happy with the system as a whole, I will add two additional injectors to the intake runners just after where it joins the plastic to the aluminum (controlled by the E-Manage) and then run 9 or more, once again depending on tuning.

This all follows how I did it on my other cars and it seems to work.

I am mechanically limited by my wastegate actuator to 7 PSI, so I will need a Profec E-01 controller to go past that.

After everything shakes out, 7 PSI or so depending on fueling.

Once I am happy with the system as a whole, I will add two additional injectors to the intake runners just after where it joins the plastic to the aluminum (controlled by the E-Manage) and then run 9 or more, once again depending on tuning.

This all follows how I did it on my other cars and it seems to work.

I am mechanically limited by my wastegate actuator to 7 PSI, so I will need a Profec E-01 controller to go past that.

Last edited by MazdaManiac; 05-06-2005 at 11:55 PM.

#80

Originally Posted by MazdaManiac

I takes me about a full minute to cut through a weld el with an 11,000 RPM angle grinder with a carbon steel cut-off wheel.

I've gotta call BS on the under a minute with a hacksaw.

It takes me more than a minute to get through an 18ga piece of mild steel 3" tubing.

The problem is the manifold is going to have a very complex shape for weld els.

The double wall design will function for strength and insulation.

I've got a pretty good handle on what I am doing. :p

I've gotta call BS on the under a minute with a hacksaw.

It takes me more than a minute to get through an 18ga piece of mild steel 3" tubing.

The problem is the manifold is going to have a very complex shape for weld els.

The double wall design will function for strength and insulation.

I've got a pretty good handle on what I am doing. :p

but after doing a full 4cly maniflod by hand I can't remember it being that hard. it was 32mm pipe which is probably smaller than what you tried.

your maniflod is looking good but the cost is looking scary compaired to the greddy kit available in japan which sould cost around $4000 us.

http://www.trust-power.com/06new/260..._turbokit.html

#83

Registered

Join Date: Oct 2001

Location: Boulder County, Colorado

Posts: 7,966

Likes: 0

Received 4 Likes

on

3 Posts

Originally Posted by MazdaManiac

0 Psi for comfirmation of no leaks then 3 PSI for testing and verification of drivability.

After everything shakes out, 7 PSI or so depending on fueling.

Once I am happy with the system as a whole, I will add two additional injectors to the intake runners just after where it joins the plastic to the aluminum (controlled by the E-Manage) and then run 9 or more, once again depending on tuning.

This all follows how I did it on my other cars and it seems to work.

I am mechanically limited by my wastegate actuator to 7 PSI, so I will need a Profec E-01 controller to go past that.

I am posting most of the new info as I go in this thread:

https://www.rx8club.com/showthread.php?t=48347

After everything shakes out, 7 PSI or so depending on fueling.

Once I am happy with the system as a whole, I will add two additional injectors to the intake runners just after where it joins the plastic to the aluminum (controlled by the E-Manage) and then run 9 or more, once again depending on tuning.

This all follows how I did it on my other cars and it seems to work.

I am mechanically limited by my wastegate actuator to 7 PSI, so I will need a Profec E-01 controller to go past that.

I am posting most of the new info as I go in this thread:

https://www.rx8club.com/showthread.php?t=48347

If you don't mind, I'm going to merge this thread and the Turbo Santa thread together. I see no reason to have to update the same project in two places... do you?

#84

Originally Posted by MazdaManiac

Scary? It is basically the same design, but mine has a bigger main flow and much uglier welds!

The Greddy kit is about $1500 more than doing it myself.

The Greddy kit is about $1500 more than doing it myself.

#85

Originally Posted by Charles R. Hill

Question for you, Jeff: Have you tried blocking the EGR valve and/or their associated ports that are built into the factory exhaust manifold? If so, did you experience detonation or other adverse effects? In designing my header, it would be much easier if I didn't need to include the crossover porting on the header flange like the factory and the RE Amemiya and FEED headers have. Thanks.

Charles

Charles

I have mine still attached, but I had to make some weird bends for the tube because it was in the way of my compressor. I may take it out and block the port, but the crossover tube is still intact.

#86

RX-7 Guru

Lookin' good, Jeff!

Few things -

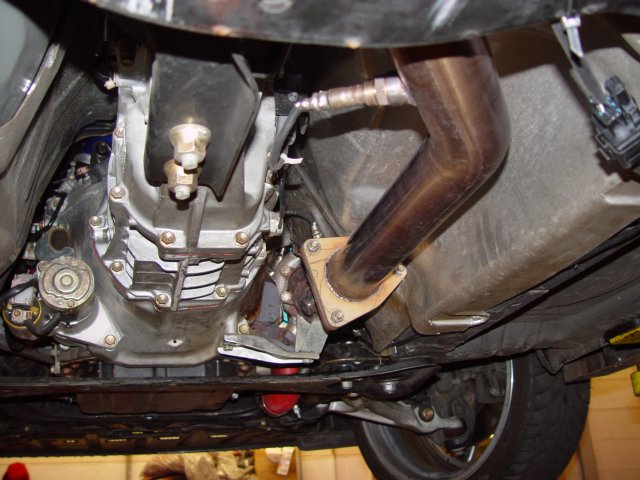

Do you have the center section of the turbo clocked at 25 deg. to make an easier oil drain path? You do know that you can spin the center section independant of the turbine/compressor housings to get a more vertical drain. I've found that good oil feed and removal is ESSENTIAL to turbo life and keeping oil from backing up and making the car smoke. I can understand if you have to angle it to keep the drain from hitting the manifold or the like.

Might be worth investing in an oil temp gauge. An oil cooled turbo will add a lot more heat load to the oil cooling system - rotaries BIG TIME use oil as one of the primary means of cooling the motor. Might be worth looking into a water cooled center section down the road.

I believe Greddy has available the aluminum oil pan that goes with their RX-8 turbo kit separately, and it already has the oil return plumbed into the pan. It also has more capacity as well. But, that might move the budget up even further .

.

Keep up the good work, and keep us posted!

Dale

Few things -

Do you have the center section of the turbo clocked at 25 deg. to make an easier oil drain path? You do know that you can spin the center section independant of the turbine/compressor housings to get a more vertical drain. I've found that good oil feed and removal is ESSENTIAL to turbo life and keeping oil from backing up and making the car smoke. I can understand if you have to angle it to keep the drain from hitting the manifold or the like.

Might be worth investing in an oil temp gauge. An oil cooled turbo will add a lot more heat load to the oil cooling system - rotaries BIG TIME use oil as one of the primary means of cooling the motor. Might be worth looking into a water cooled center section down the road.

I believe Greddy has available the aluminum oil pan that goes with their RX-8 turbo kit separately, and it already has the oil return plumbed into the pan. It also has more capacity as well. But, that might move the budget up even further

.

.Keep up the good work, and keep us posted!

Dale

#87

If you are deleting the air pump, you can probably delete the pipe, but don't quote me on that because I don't know how those ports are hooked up inside the rotor housings.

I'd say just go ahead and add it. The other manufacturers are doing it and you would still have to fab a blanking plate to block off the ports anyway - just as well make the plate a tube and put the three ports on it.

I'd say just go ahead and add it. The other manufacturers are doing it and you would still have to fab a blanking plate to block off the ports anyway - just as well make the plate a tube and put the three ports on it.

#88

Originally Posted by dcfc3s

Do you have the center section of the turbo clocked at 25 deg. to make an easier oil drain path? You do know that you can spin the center section independant of the turbine/compressor housings to get a more vertical drain. I've found that good oil feed and removal is ESSENTIAL to turbo life and keeping oil from backing up and making the car smoke. I can understand if you have to angle it to keep the drain from hitting the manifold or the like.

Originally Posted by dcfc3s

Might be worth investing in an oil temp gauge. An oil cooled turbo will add a lot more heat load to the oil cooling system - rotaries BIG TIME use oil as one of the primary means of cooling the motor. Might be worth looking into a water cooled center section down the road.

Originally Posted by dcfc3s

I believe Greddy has available the aluminum oil pan that goes with their RX-8 turbo kit separately, and it already has the oil return plumbed into the pan. It also has more capacity as well. But, that might move the budget up even further .

#91

mostly harmless

Join Date: Jun 2002

Location: Greater Vancouver Area, BC

Posts: 3,440

Likes: 0

Received 0 Likes

on

0 Posts

forget the polishing garbage. looks even better than the manifold! i really like all the little things (using as little hose for bends as possible, the enourmous spout into the sump  ).

).

the only thing left to do is get the night stills of you firing dual 3 foot flames

).

).the only thing left to do is get the night stills of you firing dual 3 foot flames

#93

Go Texas Longhorns!

A RX8 friend an I were kicking this question around yesterday, what issues are you going to have with installing a turbo/super and the multistage intake system? Is that a problem? Can that system handle the forced air? or are you going to bypass all that and run straight into the throttle body?