Building Custom Turbo for the RX-8

#276

Time to update this thread.

In the Spring of '06, about halfway between Albuquerque and Phoenix, the turbo totally stopped spooling.

Removing the manifold showed that a small amount of metal from the inner liner had come loose and lodged itself in the turbine. It caused no visible damage, but it did stop it from spinning.

The manifold itself was showing some stress cracks from movement of the turbo and contact with the frame of the car. Since I had a GReddy kit available, I switched out the manifold, turbo and downpipe and continued my tuning efforts using the smaller T618Z. The interveneing year is documented elsewhere as I pushed up the boost to double the original number and worked with several engine managment systems.

Last Wednesday, the GReddy turbo began to show signs of failure. Actually, it had shown a sign back in December when it made a really strange noise and stopped making boost. Scott at MazSport was kind enough to supply me with a turbo to replace it with, but when I got back to begin the removal process after a week away, I found that the turbo was working again normally. I just scratched my head and sent Scott's turbo back.

However, by January, I started getting smoke on a hot re-start or after extensive idling, which are both signs of oil blowby in the turbo. Then, last week, I noticed what I thought was the secondary air pump starting and stopping for an instant each time I turned the car off. Upon closer inspection, I realized that it was the turbo spooling down, which is not a noise I should be hearing.

After removing it, I found there was excessive play in the shaft.

I suspect that the turbo - already being held at the end of its efficiency range for long periods of time - was over-spun while at high RPM and mid-throttle. That was the noise I heard in December. After the bearings had cooled back down, it was able to spin again, but with too much clearance which increased over the next month and a half.

I played with all the possibilites - get a replacement GReddy turbo or re-build the current one, get a Garrett GT2871R and work the GReddy manifold to fit, buy a whole different setup or go back to my original setup.

Ultimately, it made the most sense to got back to the start. It was far less expensive and I had everything I needed in my garage.

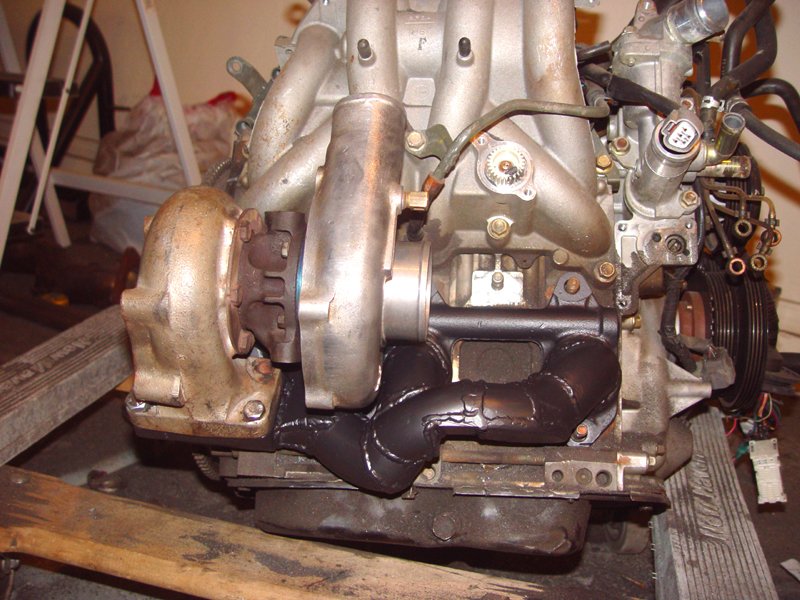

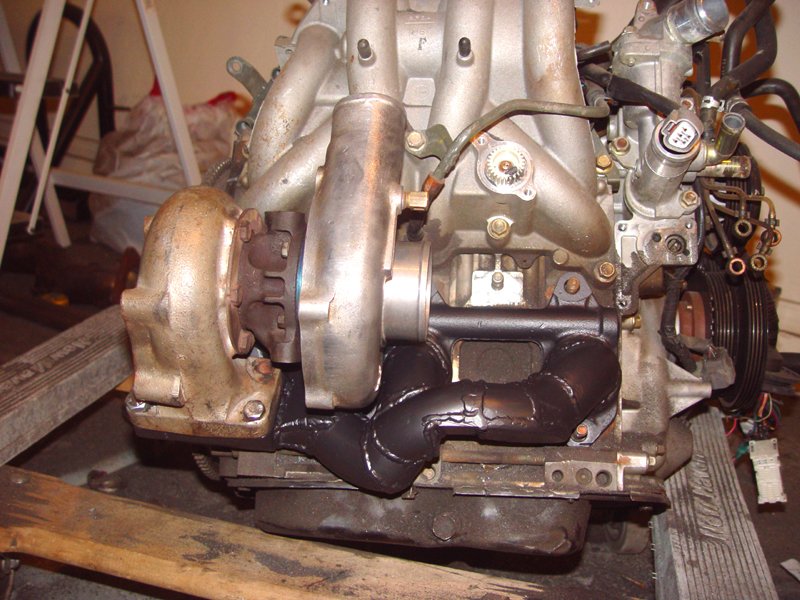

So, a week later, I present to you the new manifold for my T3/T4 hybrid:

This version is 11 GA steel instead of 18 GA and is a "runner" design rather than a log. The legs are wildly shaped to allow for the maximum room for the turbo which is several inches closer to the motor and more horizontal than the last manifold.

Internally, the front and rear legs are stepped down to equal sizes and matched to the ports. The siamese port is about 1/3 larger than the other two primaries and the throat area is as big as I could get it.

This manifold eliminates some of the problems the first one had - it doesn't require gymnastics to get the parts into the car, the bolts are more easily accessed, the "high-stress" areas right at the ports are thicker and deflected to prevent overheating and cracking and the flow is better.

The new placement angle required that I rework the engine mount. The upper bar is "flipped and raised about 1 inch to a allow the inlet of the turbo to pass through, rather than over, the mount. I can still use the OEM rubber isolator to maintain the lower NVH levels.

Having a "spare" engine laying around made it MUCH easier to fabricate the manifold. The previous version required that I test each bend while laying on my back under the car.

In the Spring of '06, about halfway between Albuquerque and Phoenix, the turbo totally stopped spooling.

Removing the manifold showed that a small amount of metal from the inner liner had come loose and lodged itself in the turbine. It caused no visible damage, but it did stop it from spinning.

The manifold itself was showing some stress cracks from movement of the turbo and contact with the frame of the car. Since I had a GReddy kit available, I switched out the manifold, turbo and downpipe and continued my tuning efforts using the smaller T618Z. The interveneing year is documented elsewhere as I pushed up the boost to double the original number and worked with several engine managment systems.

Last Wednesday, the GReddy turbo began to show signs of failure. Actually, it had shown a sign back in December when it made a really strange noise and stopped making boost. Scott at MazSport was kind enough to supply me with a turbo to replace it with, but when I got back to begin the removal process after a week away, I found that the turbo was working again normally. I just scratched my head and sent Scott's turbo back.

However, by January, I started getting smoke on a hot re-start or after extensive idling, which are both signs of oil blowby in the turbo. Then, last week, I noticed what I thought was the secondary air pump starting and stopping for an instant each time I turned the car off. Upon closer inspection, I realized that it was the turbo spooling down, which is not a noise I should be hearing.

After removing it, I found there was excessive play in the shaft.

I suspect that the turbo - already being held at the end of its efficiency range for long periods of time - was over-spun while at high RPM and mid-throttle. That was the noise I heard in December. After the bearings had cooled back down, it was able to spin again, but with too much clearance which increased over the next month and a half.

I played with all the possibilites - get a replacement GReddy turbo or re-build the current one, get a Garrett GT2871R and work the GReddy manifold to fit, buy a whole different setup or go back to my original setup.

Ultimately, it made the most sense to got back to the start. It was far less expensive and I had everything I needed in my garage.

So, a week later, I present to you the new manifold for my T3/T4 hybrid:

This version is 11 GA steel instead of 18 GA and is a "runner" design rather than a log. The legs are wildly shaped to allow for the maximum room for the turbo which is several inches closer to the motor and more horizontal than the last manifold.

Internally, the front and rear legs are stepped down to equal sizes and matched to the ports. The siamese port is about 1/3 larger than the other two primaries and the throat area is as big as I could get it.

This manifold eliminates some of the problems the first one had - it doesn't require gymnastics to get the parts into the car, the bolts are more easily accessed, the "high-stress" areas right at the ports are thicker and deflected to prevent overheating and cracking and the flow is better.

The new placement angle required that I rework the engine mount. The upper bar is "flipped and raised about 1 inch to a allow the inlet of the turbo to pass through, rather than over, the mount. I can still use the OEM rubber isolator to maintain the lower NVH levels.

Having a "spare" engine laying around made it MUCH easier to fabricate the manifold. The previous version required that I test each bend while laying on my back under the car.

#278

Originally Posted by gh0st

nice... so i take it no gt28r?

The main reason to go to that turbo is packaging - it will fit on the GReddy manifold.

Since I can fabricate my own manifold, it was a wash and I get to keep my money.

Originally Posted by Charles R. Hill

Any chance there is an oil delivery/temperature problem that is cooking the center bearings?

However, it doesn't look cooked.

#279

Original Turbo 'd Auto !!

When I rebuilt my gredy turbo it didn't have that much play in the shaft.

It still had some though.

Were you running a restrictor on the oil line to the turbo Jeff?

And when I install mine I'll have you come over to the shop and help.

It still had some though.

Were you running a restrictor on the oil line to the turbo Jeff?

And when I install mine I'll have you come over to the shop and help.

#280

Originally Posted by 09Factor

When I rebuilt my gredy turbo it didn't have that much play in the shaft.

It still had some though.

Were you running a restrictor on the oil line to the turbo Jeff?

And when I install mine I'll have you come over to the shop and help.

It still had some though.

Were you running a restrictor on the oil line to the turbo Jeff?

And when I install mine I'll have you come over to the shop and help.

The amount of play mine has allows the turbine and compressor wheel to touch the housings!

I do have a restrictor. Always.

Let me know when you start the install.

I'm almost done here. I'll probably start it tonight after I make a checklist.

#282

Consiglieri

Join Date: Feb 2004

Location: yourI'mgirl

Posts: 1,275

Likes: 0

Received 0 Likes

on

0 Posts

As far as the oil temp being the problem with the bearings, I doubt it. I've had my extra oil cooler (which, incedentally came off a NASCAR) installed since I've had the turbo installed. I've had the little guy rebuilt once, and its due for another already. There wasn't any sign of oil coke the first time around. The bearings were just worn the F out. So I don't think its the oil temp.

Looking at the closest compressor maps that we have for this turbo, I'm sure that I'm running the turbo past the choke line at the PRs I'm running. Plotting the demand lines shows that the boost should fall off right at 6k - which is exactly what happens. When you run the turbo into that part of the map, the speed increases *dramatically*. Journal bearings don't last long when you're consistently over-spinning the turbo. I believe this is why the GReddy's aren't lasting very long. They are being run past the choke line as people turn-up the boost. They're just too small to flow what the Renesis demands at higher PRs.

Looking at the closest compressor maps that we have for this turbo, I'm sure that I'm running the turbo past the choke line at the PRs I'm running. Plotting the demand lines shows that the boost should fall off right at 6k - which is exactly what happens. When you run the turbo into that part of the map, the speed increases *dramatically*. Journal bearings don't last long when you're consistently over-spinning the turbo. I believe this is why the GReddy's aren't lasting very long. They are being run past the choke line as people turn-up the boost. They're just too small to flow what the Renesis demands at higher PRs.

#283

Consiglieri

Join Date: Feb 2004

Location: yourI'mgirl

Posts: 1,275

Likes: 0

Received 0 Likes

on

0 Posts

I think only the one turbo had bearing issues. I have a home-made pill which is a good bit smaller than Jeff's restrictor. If memory serves me, Jeff's is 0.0625". Mine is 0.045" and the thing still is smoking. GReddy definintely F'd up. They gave us a turbo which chokes in the high RPM even at the PR they intended.

I'm not saying there's no way Jeff's turbo failing (which I think is probably exactly the same mechanism as the other GReddy failures documented here) is oil related. I'm just saying that even with restrictors of varying sizes and oil coolers the turbos are still failing. Reading the maps, we're over spinning them, which is known to cause premature failure of the journal bearings.

I'm not saying there's no way Jeff's turbo failing (which I think is probably exactly the same mechanism as the other GReddy failures documented here) is oil related. I'm just saying that even with restrictors of varying sizes and oil coolers the turbos are still failing. Reading the maps, we're over spinning them, which is known to cause premature failure of the journal bearings.

#285

Big nod to MD - that pretty much sums it up.

The right side of the flow map goes from all to nothing, so to speak, pretty rapidly. When you get to 1 BAR of boost at 32 lbs or so, the stack goes from 72% to choke in about .5 lbs.

The previous turbo "failure" wasn't a failure at all - a price of junk got stuck in the turbine like a stick in a bicycle wheel. The turbo survived that just fine and is back on the car right now.

The GReddy unit was brand new one year ago, so its been about 10k miles or so.

The right side of the flow map goes from all to nothing, so to speak, pretty rapidly. When you get to 1 BAR of boost at 32 lbs or so, the stack goes from 72% to choke in about .5 lbs.

The previous turbo "failure" wasn't a failure at all - a price of junk got stuck in the turbine like a stick in a bicycle wheel. The turbo survived that just fine and is back on the car right now.

The GReddy unit was brand new one year ago, so its been about 10k miles or so.

#286

Originally Posted by Charles R. Hill

I wonder just what that foreign material was?

Apparently, my weld wasn't very good and it broke loose.

It was sitting in the throat of the manifold when I pulled it off.

BTW - You can get a pretty decent sunburn while welding!

I bought a pair of welding goggles so that I'd have an easier time under the car then I did with a full-face helmet.

I ended up wearing them all the time and now I have a band of sunburn across my forehead and the tip of my nose!

I've lived in Phoenix for a year with no sunburn, but I manage to get one in three days of welding!

Last edited by MazdaManiac; 02-16-2007 at 02:59 PM.

#288

RotoRocks Powered

I was re-welding the after-turbo piece on mine last sunday, and burned my face and forearms so much that the skin is is now peeling. :-)

It was read like I spend a day in the sun with no sunblock.

Gotta watch out for that UV

It was read like I spend a day in the sun with no sunblock.

Gotta watch out for that UV

#289

Originally Posted by turbosa22c

why would you want to restict flow to your turbo? to me thats like putting a blockage before the component that needs oil. your starving your turbo

You are starving you mind.

#290

if you ask me. the problem is the return line. if you have aq smoking turbo and you suspect its leaking pass the bearing. and the turbo is relatively new. oil return line is suspect. the greddy position just sucks for a oil return. it drains below the oil level and it has to drain forward, fighting forward motion. oil needs to be drained quickly to prevent it from backing up. my suggestion is to use a return pump and drain it back up, maybe into the oil cap area. i had similar problem once on a rotary conversion on a 911. the manifold that was made hung to low, causing oil to back up.

#291

Consiglieri

Join Date: Feb 2004

Location: yourI'mgirl

Posts: 1,275

Likes: 0

Received 0 Likes

on

0 Posts

Not to be mean, but... Oh wtf. You have no idea what you are talking about. We've been studying this system now for 3 years. The turbo is above the oil line in the pan. Hence, it drains just fine. The journal bearings need surprisingly little oil. Its getting WAY too much with the standard Greddy oil line. Everyone that I know of that builds these systems puts a 0.065 restrictor in the oil line. Its just good practice.

#292

Originally Posted by rotorocks

I was re-welding the after-turbo piece on mine last sunday, and burned my face and forearms so much that the skin is is now peeling. :-)

It was read like I spend a day in the sun with no sunblock.

Gotta watch out for that UV

It was read like I spend a day in the sun with no sunblock.

Gotta watch out for that UV

Your arms? You weld with your arms bare?

I'd be so scarred-up if I did that.

#295

RotoRocks Powered

MM

I welded off the car. No worries about stuff dripping on me :-)

Scavenging oil with a pump is not so bad, as long as the pump is the right size and it is far enough from the turbo for the oil to cool off enough not to damage the pump.

My pump (after quite a bit of experimenting ) seems to be doing an excellent job removing that oil from under the turbo and pumping it up through the oil cap.

) seems to be doing an excellent job removing that oil from under the turbo and pumping it up through the oil cap.

The restrictor is used because too much oil in the turbo bearing creates unnecessary pressure on the seals. they are not designed to keep oil from coming out, but rather to keep pressure outside from getting in.

1/4" oil feed will flows way too much oil from the engine and it builds up faster than it can drain on it's own and that causes problems.

I welded off the car. No worries about stuff dripping on me :-)

Scavenging oil with a pump is not so bad, as long as the pump is the right size and it is far enough from the turbo for the oil to cool off enough not to damage the pump.

My pump (after quite a bit of experimenting

) seems to be doing an excellent job removing that oil from under the turbo and pumping it up through the oil cap.

) seems to be doing an excellent job removing that oil from under the turbo and pumping it up through the oil cap.

Originally Posted by turbosa22c

well you guys do what you want to do. I'll do it my way, you do it your way.

1/4" oil feed will flows way too much oil from the engine and it builds up faster than it can drain on it's own and that causes problems.

#297

Note to self:

Remember to put the circlip back on the wastegate actuator or you will have no boost.

Second note to self:

Remember to tighten the T-bolt clamp at the turbo outlet or you won't have much boost.

Third note to self:

Header wrap rocks, but it only works on the parts that are actually covered. The other parts are hot.

That is all.

Remember to put the circlip back on the wastegate actuator or you will have no boost.

Second note to self:

Remember to tighten the T-bolt clamp at the turbo outlet or you won't have much boost.

Third note to self:

Header wrap rocks, but it only works on the parts that are actually covered. The other parts are hot.

That is all.

#299

Oh yeah. She's all back together. Nothing leaking, though I haven't had the chance to kick the crap out of it yet.

I'll probably do some late-night drag runs out on Pecos tomorrow. I need to verify the tuning before the dyno session the following Saturday.

I've got better flow on both sides of the equation, so I want to take advantage of that before then.

It is certainly nice to not see or smell oil smoke!

I'll probably do some late-night drag runs out on Pecos tomorrow. I need to verify the tuning before the dyno session the following Saturday.

I've got better flow on both sides of the equation, so I want to take advantage of that before then.

It is certainly nice to not see or smell oil smoke!