THK Endlinks

#1

THK Endlinks

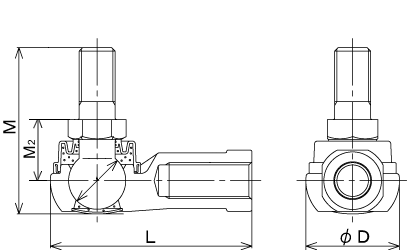

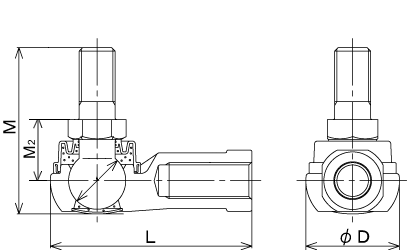

I've been reading about these in search for an upgrade and adjustability in endlink. These are Powergrid endlinks which use a sealed THK resin ball joint (no rattle or maintenance/replacement cycles like a heim joint) which provides 50 degrees of articulation (as opposed to 20 degrees from a standard heim joint).

I've been reading really good reviews at the mini and 350z forums regarding this product.

This pic is from a 350z forum as a comparo shot over stock.

edit: pic added

www.powergridinc.com

http://www.thk.com/

Only drawback is that they're $155 a pair. Not exactly AWR cheap, but the Whiteline adjustables (heim with rubber grommets) could be had for about $100 less for the set of four.

And yes, yes, I know.... our OEM endlinks are not bad at all (I'm sure they're much stronger/stiffer/capable than they look), but I'm looking to guage if there's any discernable change in the stock swaybar set's feedback by changing out the rubber bushings to poly and the endlinks to an aftermarket link.

I've been reading really good reviews at the mini and 350z forums regarding this product.

This pic is from a 350z forum as a comparo shot over stock.

edit: pic added

www.powergridinc.com

http://www.thk.com/

Only drawback is that they're $155 a pair. Not exactly AWR cheap, but the Whiteline adjustables (heim with rubber grommets) could be had for about $100 less for the set of four.

And yes, yes, I know.... our OEM endlinks are not bad at all (I'm sure they're much stronger/stiffer/capable than they look), but I'm looking to guage if there's any discernable change in the stock swaybar set's feedback by changing out the rubber bushings to poly and the endlinks to an aftermarket link.

Last edited by SouthFL; 03-10-2008 at 05:12 PM.

#3

No respecter of malarkey

iTrader: (25)

it depends on the quality of the heim joints, good ones that last cost 3x - 4x more than cheap ones that will be clunking in no time

those look like cheap industrial joints to me as opposed to a quality heim joint with a stud staked into it, they generally tend not to have a very high strength rating which equates to fast wear

you can buy those particular parts and assemble them yourself from any number of suppliers/manufacturers

those look like cheap industrial joints to me as opposed to a quality heim joint with a stud staked into it, they generally tend not to have a very high strength rating which equates to fast wear

you can buy those particular parts and assemble them yourself from any number of suppliers/manufacturers

#4

I agree, the look seems not so reassuring.

Yet, the ball link itself may indeed be of high quality.

A comment like this one from the 350z site is very impressive (though, the guy is now a reseller, so it is biased):

Grassroots Motorsports had a write-up about the links as well (then again, Powergrid is an advertiser in the mag).

http://grassrootsmotorsports.com/new...s/1997-bmw-m3/

Yet, the ball link itself may indeed be of high quality.

A comment like this one from the 350z site is very impressive (though, the guy is now a reseller, so it is biased):

I can guarantee you one thing...you will not find a better endlink than the Powergrid. After buying every other aftermarket endlink and trying each out on my own car (as we were preparing to release our own solid endlink), we came across the Powergrid. The components they use are absolutely the best on the market, are completely sealed against dirt and moisture, need no maintenance. I was so impressed with them, we stopped the development/testing on our own in house units and became Powergrids 350Z distributor.

They have 50 degrees of articulation, are adjustable (for those track junkies who really want to play with swaybar preload/cornerbalancing)

They have 50 degrees of articulation, are adjustable (for those track junkies who really want to play with swaybar preload/cornerbalancing)

Grassroots Motorsports had a write-up about the links as well (then again, Powergrid is an advertiser in the mag).

http://grassrootsmotorsports.com/new...s/1997-bmw-m3/

Last edited by SouthFL; 03-10-2008 at 09:36 PM.

#5

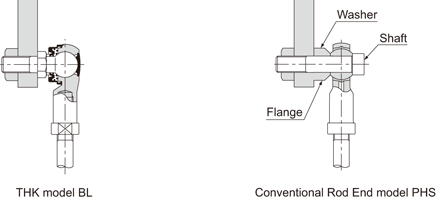

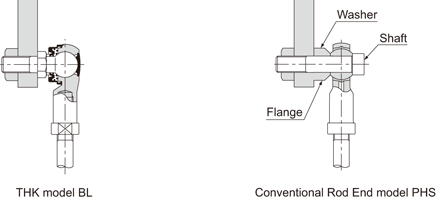

Another diagram:

[Comparison of THK Link Ball and the Conventional Rod End]

● Sine it has a shaft, model BL can easily be installed (especially useful for rod assembly).

● Because of the improved shape of the boot lip, the spherical area is protected from muddy water even in a muddy atmosphere.

● Since it contains grease, it can be used without further lubrication. (with the boot attached)

● Unlike the conventional type, which has a clearance between the shaft and the inner circumference of the inner ring and cannot be fixed completely, model BL has minimum distortion and high rigidity since the shank is integrated with the ball.

[Comparison of THK Link Ball and the Conventional Rod End]

● Sine it has a shaft, model BL can easily be installed (especially useful for rod assembly).

● Because of the improved shape of the boot lip, the spherical area is protected from muddy water even in a muddy atmosphere.

● Since it contains grease, it can be used without further lubrication. (with the boot attached)

● Unlike the conventional type, which has a clearance between the shaft and the inner circumference of the inner ring and cannot be fixed completely, model BL has minimum distortion and high rigidity since the shank is integrated with the ball.

#7

Here's another assembled pic:

Along with the text from z1auto.com

For those running lowered cars, wide wheels and tires, stiffer swaybars, coilovers, having the ability to adjust the endlink is invaluable. It allows you to safely and carefully adjust the handling characteristics of the car in a quick and easy fashion. These links allow for up to 50 degrees of articulation, meaning that their ability to deal with stiff sways, stiff springs, and various load chores are seamless. These links use a genuine THK ball link end joing. Each THK Ball Link is composed of a high-precision ball bearing, a die-cast holder, and a shank connected to the ball by a special welding method. Through a unique production process, the mirror surface of the ball bearing is copied onto the inner mounting surface for perfect contact between them, achieving outstanding wear resistance, exceedingly smooth motion, and high strength.

Unlike the other, more common heim joint style units, these are fully sealed, never require greasing, and are completely water tight and dust tight. In addition, you never have to worry about these links developing noise issues down the road due to the design of their ball joint ends. The dual lock nuts on either end of the link means that the length of the link will not change over time, which can happen on other style endlinks which only use 1 lock nut. In addition, the other style links on the market are not sealed units, so dust, grime, sand, and moisture is ever present, and leads to increased NVH (noise, vibration and harshness) and

limited articulation.

Unlike the other, more common heim joint style units, these are fully sealed, never require greasing, and are completely water tight and dust tight. In addition, you never have to worry about these links developing noise issues down the road due to the design of their ball joint ends. The dual lock nuts on either end of the link means that the length of the link will not change over time, which can happen on other style endlinks which only use 1 lock nut. In addition, the other style links on the market are not sealed units, so dust, grime, sand, and moisture is ever present, and leads to increased NVH (noise, vibration and harshness) and

limited articulation.

#8

No respecter of malarkey

iTrader: (25)

just because it doesn't make noise doesn't mean it's not allowing uncontrolled movement under load, it just has some internal springs to keep it from rattling

if you want a quality endlink set get some Aurora PRM-T/PRM-T heims with the staked stud option and there are options for boots too. These alone will cost you $50+ each x 4 per axle, plus the cost of other needed hardware; the threaded jacking bolt, jam nuts, washers, and stud nuts

if you want a quality endlink set get some Aurora PRM-T/PRM-T heims with the staked stud option and there are options for boots too. These alone will cost you $50+ each x 4 per axle, plus the cost of other needed hardware; the threaded jacking bolt, jam nuts, washers, and stud nuts

#12

Well I might be just a tad biased because I work for THK but I am being honest when I tell you there isn't a better link on the market. I am not here to spam for THK though just wanted give some advise if you do choose to use THK links get the resin lined ones.

I am responsible for the testing of the links and when we test the resin ones we do it without grease and they last more life cycles then anything available on the market. Of course they are sold with grease in them. The grease by the way is a certain type of Shell alvania which reacts to temperature changes accordingly.

Also because the bearing is cast in the link instead of press fit they are truly round. As far as strength goes the minimum allowable tolerance for tensile testing is 2800 KNF and for stud ball push off (or break) is 3500 knf. The weld is so strong that when we do the break test we actually break inside the ball leaving it concave.

Again not trying to sell links for one thing we only sell to OEM's not sure how Power Grid and companies like them are getting the links. If you can figgure it out you could build your own much much cheaper.

Oh yeah there are no internal springs to reduce noise in the metal type (Non-Resin) We very tightly control the axial and radial clearences which in turn helps control noise and load. In the resin links clearance is very minimal and due to no metal to metal contact no noise. The cut away above is of a metal link I will get some more drawings posted if anyone is interested of resin links so you can clearly see the advantage.

I am responsible for the testing of the links and when we test the resin ones we do it without grease and they last more life cycles then anything available on the market. Of course they are sold with grease in them. The grease by the way is a certain type of Shell alvania which reacts to temperature changes accordingly.

Also because the bearing is cast in the link instead of press fit they are truly round. As far as strength goes the minimum allowable tolerance for tensile testing is 2800 KNF and for stud ball push off (or break) is 3500 knf. The weld is so strong that when we do the break test we actually break inside the ball leaving it concave.

Again not trying to sell links for one thing we only sell to OEM's not sure how Power Grid and companies like them are getting the links. If you can figgure it out you could build your own much much cheaper.

Oh yeah there are no internal springs to reduce noise in the metal type (Non-Resin) We very tightly control the axial and radial clearences which in turn helps control noise and load. In the resin links clearance is very minimal and due to no metal to metal contact no noise. The cut away above is of a metal link I will get some more drawings posted if anyone is interested of resin links so you can clearly see the advantage.

Last edited by durtydawg; 02-27-2009 at 07:02 PM.

#14

Sorry, Like I said I am not a salesman I just work at THk, you would have to purchase links through Power grid or someone like that. Again if you could find where they are getting the link ends you could make your own. the rod the are using to connect the ends should be an M12 and just standard m12 jam nuts of course the rod would have to be left hand thread on one end and right hand on the other. The same with links one left and one right.

You might try contacting sales at THK.com it is located in Chicago. Again I work at the Manufacturing Facility in Hebron Ohio and as far as I know we only sell to OEMs there. I am sure you will find if you built your own you could build them allot cheaper.

You might try contacting sales at THK.com it is located in Chicago. Again I work at the Manufacturing Facility in Hebron Ohio and as far as I know we only sell to OEMs there. I am sure you will find if you built your own you could build them allot cheaper.

#15

Registered

iTrader: (1)

I know this is a year old thread, but has anyone tried these? The appeal for me is that they appear to be somewhat sealed.

My set of year-old AWR endlinks has gotten VERY noisy and I'd pay a lot for an alternative that has normal nuts on the end (unlike the annoying double-hex-nut setup like the OEM's) and is sealed such that they wont get crap in them and degrade into a very loud set of clunking links.

My set of year-old AWR endlinks has gotten VERY noisy and I'd pay a lot for an alternative that has normal nuts on the end (unlike the annoying double-hex-nut setup like the OEM's) and is sealed such that they wont get crap in them and degrade into a very loud set of clunking links.

#16

No respecter of malarkey

iTrader: (25)

They're sealed, but they're not rated for high loads, the issue in general is that quality Teflon lined heim joints cost $$$ and people in general are cheap ... especially RX-8 people ...

I discounted making a set back in 2005

Just replace the ends on your AWRs, pm me for a recommendation.

Btw, almost every heim manufacturer can supplied staked studs in their joints

.

I discounted making a set back in 2005

Just replace the ends on your AWRs, pm me for a recommendation.

Btw, almost every heim manufacturer can supplied staked studs in their joints

.

Last edited by TeamRX8; 07-09-2010 at 08:54 PM.

Thread

Thread Starter

Forum

Replies

Last Post

{FS/WTT} 04 Black Rx-8 TRACK AUTOX TIMEATTACK

Billy Marcial

RX-8's For Sale/Wanted

5

03-01-2018 06:50 AM

92tsiawd

Series I Wheels, Tires, Brakes & Suspension

6

06-25-2006 05:10 PM

carbonRX8

Series I Wheels, Tires, Brakes & Suspension

21

08-30-2005 09:28 PM

brillo

Series I Wheels, Tires, Brakes & Suspension

6

09-27-2004 08:15 PM