AxialFlow Brake Master Cylinder Brace

#54

zoom-zoom

iTrader: (1)

I didn't see these on the AxialFlow web site. Are they available yet?

#55

M6? You are thinking of the studs that hold the strut bar. They are M8p1.25.

The three strut bosses are really, really tough. If you break them, you have other problems to contend with!

Rich hasn't offered it for sale quite yet, but I think it is forthcoming.

Just a quick review:

It is nicely machined, takes very little effort to install and it works. The pedal is like rock now, instead of paper (or maybe scissors).

The three strut bosses are really, really tough. If you break them, you have other problems to contend with!

Rich hasn't offered it for sale quite yet, but I think it is forthcoming.

Just a quick review:

It is nicely machined, takes very little effort to install and it works. The pedal is like rock now, instead of paper (or maybe scissors).

#56

Registered

iTrader: (5)

Yes you're a pretty boy.

You have the production nuts with the domed head.

What's that they say, if it don't go chrome it.

I was just waiting for some feedback before marketing them.

There are a bunch machined and at the anodizer now.

I will run the nuts Friday. Take some more pictures and put it up on the website.

What do ya bet Jeff would like his red to match his hoses?

Suffer with it bare buddy.

You have the production nuts with the domed head.

What's that they say, if it don't go chrome it.

I was just waiting for some feedback before marketing them.

There are a bunch machined and at the anodizer now.

I will run the nuts Friday. Take some more pictures and put it up on the website.

What do ya bet Jeff would like his red to match his hoses?

Suffer with it bare buddy.

#58

Power!!

I received mine today and just installed it sans strut tower brace to check fitment. It's a very nicely machined piece Richard. I will be cutting my strut tower brace and installing it as soon as I get the right tools and go to China for a week.

The only problem I had is my 22mm open end wrench didn't quite fit over the nut heads so it was a bit tough to tighten down. That and I don't have a 22mm socket. so I guess I'll pick one up.

so I guess I'll pick one up.

You'll need a 22mm socket for the brace mounting nuts, 17mm open end wrench to tighten the master cylinder support spacer, 12mm socket to remove the strut tower brace, 14mm socket to take off the shock mount nuts.

I need to get a hole saw that's made to cut metal. My wood set is too aggressive and won't bite on the strut tower brace. A drill press would definitely be nice and clean.

I haven't been able to drive it yet tonight but one observation is that the master cylinder definitely sags at rest. When tightening down the spacer nut it definitely pushed the master cylinder back and up. Geez this thing can't even hold it's own weight...

I have some pictures though...

pieces that come with the kit

strut tower after removing brace

the mounting nuts fit on the shock bolts nicely.

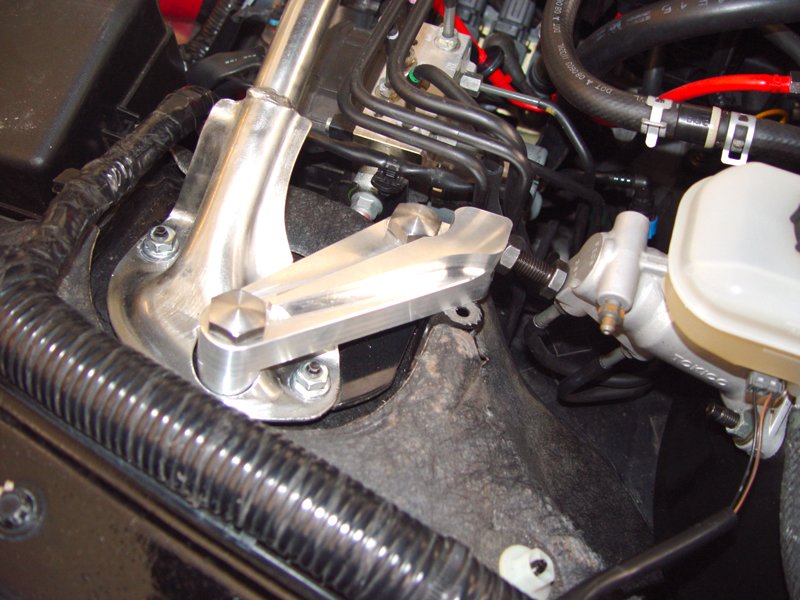

checking the positioning and fitment. Looks very good.

brake master cylinder spacer. I guess you call this the "business end"

installed

contact point with the brake master cylinder

The only problem I had is my 22mm open end wrench didn't quite fit over the nut heads so it was a bit tough to tighten down. That and I don't have a 22mm socket.

so I guess I'll pick one up.

so I guess I'll pick one up.You'll need a 22mm socket for the brace mounting nuts, 17mm open end wrench to tighten the master cylinder support spacer, 12mm socket to remove the strut tower brace, 14mm socket to take off the shock mount nuts.

I need to get a hole saw that's made to cut metal. My wood set is too aggressive and won't bite on the strut tower brace. A drill press would definitely be nice and clean.

I haven't been able to drive it yet tonight but one observation is that the master cylinder definitely sags at rest. When tightening down the spacer nut it definitely pushed the master cylinder back and up. Geez this thing can't even hold it's own weight...

I have some pictures though...

pieces that come with the kit

strut tower after removing brace

the mounting nuts fit on the shock bolts nicely.

checking the positioning and fitment. Looks very good.

brake master cylinder spacer. I guess you call this the "business end"

installed

contact point with the brake master cylinder

#59

Registered

iTrader: (5)

It's not really 22 mm try 7/8 inch. Sorry about that but try buying 22mm hex stock, not. 7/8 hex bar is the best I can do. It has to be at least that size to cover the counter bore. The bore is the same depth as the nut is long, so the thickness of the hardened steel washer is the clearence to the bottom.

We could have just put nuts at the bottom but holding it from on top makes it much stronger.

Now just because you have your 1/2 breaker bar on a 7/8 socket doesn't mean tighten it down like a lug nut. Remember it is only a 10mm stud. I think I better come up with a torque number for this before mass selling. You just know someone will rip their stud out if not warned.

Also I don't know just yet how much to preload the master cyld. I used 1 flat on the bolt after contact. You could use more but why. Wait I know why, because it might rattle if there is not enough preload. Lets try 2 flats to start with. How much did MM use?

One more thing MM it's 10x 1.25 thread, I know because I taped the first set wrong and had to make 2 more for my car.

We could have just put nuts at the bottom but holding it from on top makes it much stronger.

Now just because you have your 1/2 breaker bar on a 7/8 socket doesn't mean tighten it down like a lug nut. Remember it is only a 10mm stud. I think I better come up with a torque number for this before mass selling. You just know someone will rip their stud out if not warned.

Also I don't know just yet how much to preload the master cyld. I used 1 flat on the bolt after contact. You could use more but why. Wait I know why, because it might rattle if there is not enough preload. Lets try 2 flats to start with. How much did MM use?

One more thing MM it's 10x 1.25 thread, I know because I taped the first set wrong and had to make 2 more for my car.

Last edited by Richard Paul; 02-13-2008 at 01:56 AM.

#60

Power!!

Thanks for the info. Richard. I'll take a look at a 7/8" socket. Good idea on the torque specs. The bolts that were on the studs before were 30 ftlbs.

What do you mean by 1 flat on the bolt? I'm not familiar with your term.

What do you mean by 1 flat on the bolt? I'm not familiar with your term.

#61

Now just because you have your 1/2 breaker bar on a 7/8 socket doesn't mean tighten it down like a lug nut. Remember it is only a 10mm stud. I think I better come up with a torque number for this before mass selling. You just know someone will rip their stud out if not warned.

Yeah, I should have known that as well. There aren't too many 1.5 pitch threads on that car.

#62

Registered

iTrader: (5)

There are 6 flats on a hex head screw. The term comes from adjusting the "barrel valve" on drag race type fuel injection. A left and right hand turnbuckle that connects the fuel valve to the butterflys. This richens or leans the low speed mixture. More tech term would be moves the fuel ramp in relation to the butterflys. Because there really is no slow speed system in drag racing.

"Richen it one flat" might be heard in a drag pit.

Top fuel cars are not allowed electronic injection. They don't make nozzles big enough anyway. TF cars burn a gallon a second. @$50 a gal. That's not bad they use 8 pistons every 4.5 sec too.

MM we're on the same page, 1/4 of 6= 1.5 flats

Last edited by Richard Paul; 02-13-2008 at 10:42 AM.

#63

Power!!

Ah. Thanks for the explanation. I'm going to start speaking in flats now too.

Any thoughts on whether or not there is any adverse affects of pre-loading the master cylinder? I basically adjusted it out until the master cylinder resisted so it is pushed up and back some maybe 1/4" to 1/2" total. I didn't crank it. Just adjusted it until it wouldn't move back easily.

I drove the car this morning and the brake pedal feels fabulous! It's got the travel and modulation consistency I'm looking for. It's nice and tight and I can feel the brakes grab as soon as I touch the pedal and the force ramps up really nicely.

Richard this is a great product!!

Any thoughts on whether or not there is any adverse affects of pre-loading the master cylinder? I basically adjusted it out until the master cylinder resisted so it is pushed up and back some maybe 1/4" to 1/2" total. I didn't crank it. Just adjusted it until it wouldn't move back easily.

I drove the car this morning and the brake pedal feels fabulous! It's got the travel and modulation consistency I'm looking for. It's nice and tight and I can feel the brakes grab as soon as I touch the pedal and the force ramps up really nicely.

Richard this is a great product!!

#67

Power!!

Okay. I'll loosen it up some. I figured if there was some preload on it there would be less flexing of the pieces themselves.

I'm definitely not cranking it down though. Just a little preload on the assembly so all the flexy parts are flexed back a bit.

I'm definitely not cranking it down though. Just a little preload on the assembly so all the flexy parts are flexed back a bit.

#68

I don't buy Kool-Aid

#69

Registered

iTrader: (5)

It'll be up on the site sometime this week.

Meanwhile you can send Paypal $70.00 plus $12.00 for S&H

to: axcharg@socal.rr.com

With your name and address plus your color choice. Blue, Red or Bare.

It'll go out by Priority Mail the next day. Or if it's early enough the same day.

And the faster they move the higher the pressure and the faster sound moves.

Last edited by Richard Paul; 02-16-2008 at 12:40 PM.

#71

Registered

iTrader: (5)

[There is no reason to load the MC back to where it came from, that puts full time stress where it was never ment to be. All we are trying to do is keep it from moving foward. If it wouldn't rattle we would just use contact and no more.

Loading it one flat is .010". A piece of copy paper is .005" so you've pushed it back the thickness of 2 pieces of paper. If you go as MM has 1/4 turn then you've moved it .015" or three peices of paper.

That is all it takes and will not hurt anything while keeping it from moving foward.

Turning the screw is EZ and you forget the power of the ramp. So turning it until you get resistance is dumb, the parts are so flimsy that it can go a long way until you feel something. You're not punishing it for being flimsy just limiting it.

Loading it one flat is .010". A piece of copy paper is .005" so you've pushed it back the thickness of 2 pieces of paper. If you go as MM has 1/4 turn then you've moved it .015" or three peices of paper.

That is all it takes and will not hurt anything while keeping it from moving foward.

Turning the screw is EZ and you forget the power of the ramp. So turning it until you get resistance is dumb, the parts are so flimsy that it can go a long way until you feel something. You're not punishing it for being flimsy just limiting it.

#72

Administrator

iTrader: (7)

Make little sense, your argument does.

- Yoda

#73

road warrior

Join Date: Feb 2006

Location: Oakland and Los Angeles, CA

Posts: 1,861

Likes: 0

Received 3 Likes

on

3 Posts

There's a difference between lawyer speak recommendations and actual engineering recommendations. They might sound close to the same in wording, but the difference is there.

Last edited by LionZoo; 02-17-2008 at 05:19 PM.

#74

Well, the other issue is that pre-loading it will distort its position pretty obviously, so it really is a moot point.

Turn it 'till it touches and lock it down.

That is enough.

I did an autocross day today. Since it was a practice day, I got a lot (15) of runs in and really got to beat the thing up a lot.

The AF brace makes a huge difference to pedal feel at the limit.

Huge.

Turn it 'till it touches and lock it down.

That is enough.

I did an autocross day today. Since it was a practice day, I got a lot (15) of runs in and really got to beat the thing up a lot.

The AF brace makes a huge difference to pedal feel at the limit.

Huge.