PPort MSP

#76

Boostin'

Thread Starter

Pretty crazy how well Renesis flows compared to older rotaries, it seems that zero overlap helps with supposedly restrictive exhaust ports Or is it in the top-end?

Or is it in the top-end?

Did the fuel flow correlated with measured power? I'm pretty sure it did, otherwise you wouldn't post it with such confidence

Or is it in the top-end?

Or is it in the top-end?Did the fuel flow correlated with measured power? I'm pretty sure it did, otherwise you wouldn't post it with such confidence

#77

Release the twins.

I thought the only purpose of the third ring was to prevent exhaust contamination into the intake? I don't see a necessary reason to spend all the money to have rotors machined because of a lil more dilution. I have about 10k miles on a 6port renesis with 8.5:1 rotors and a Borg Warner s363 with out any problems.

So just curious as why you machined for them. Maybe I missed something.

So just curious as why you machined for them. Maybe I missed something.

#78

Are you on Rcc?

Not trying to stir up a lot here but there has always seemed to be quite a bit of mis-information on this site.

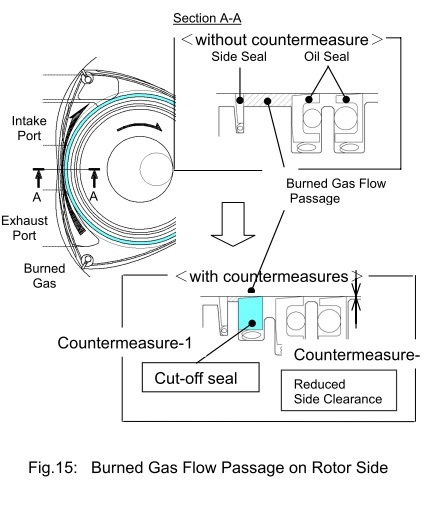

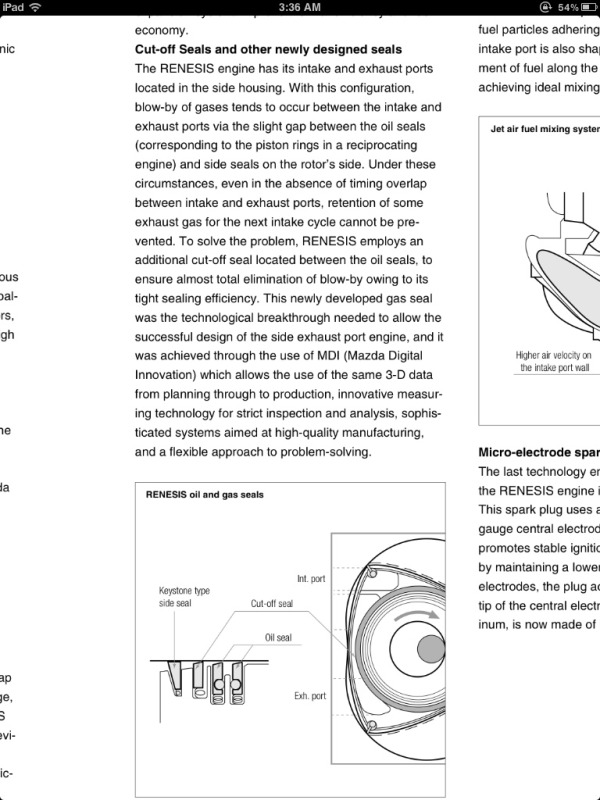

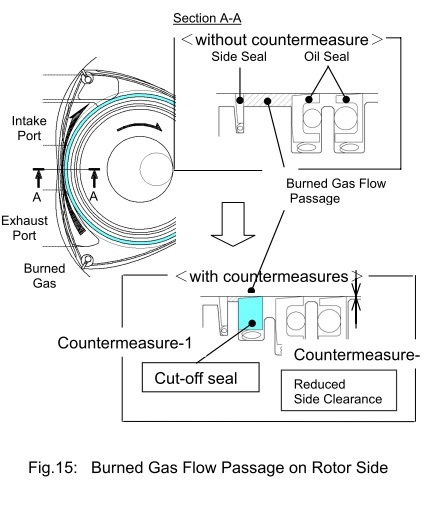

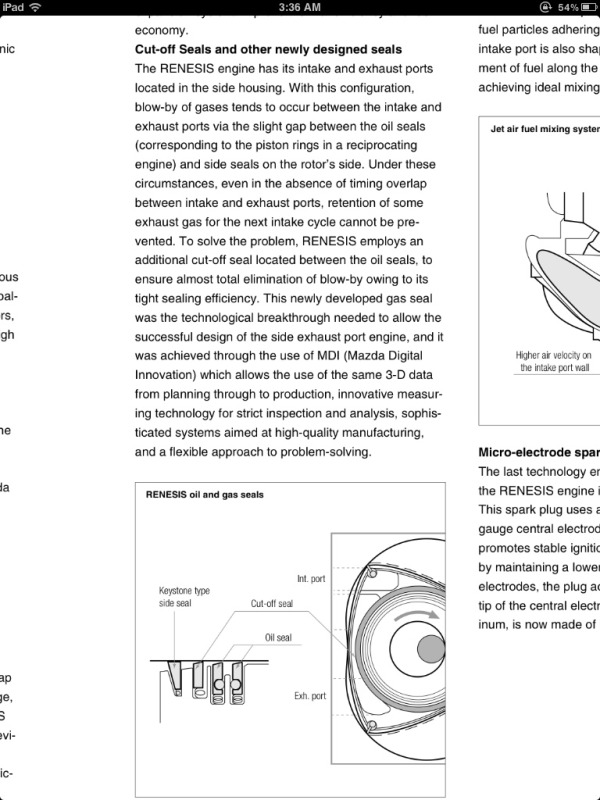

No where in these papers does it mention that the cutoff seal was deployed to help keep heat off the control rings. It's merely a way of keeping egr down In order to provide better emissions and leaner idle afrs.

Now not saying that it prob does help but until someone has proof or has a sae paper stating that I'm going to trust what I've done and what I've seen. And that happens to be that the cutoff does dick for a performance minded motor. If this wasn't the case you would've seen wear on the older rotaries from the same problem..... Outta all of our race engine(1000rwhp mind you) we have never seen a issue of such.

Not trying to stir up a lot here but there has always seemed to be quite a bit of mis-information on this site.

No where in these papers does it mention that the cutoff seal was deployed to help keep heat off the control rings. It's merely a way of keeping egr down In order to provide better emissions and leaner idle afrs.

Now not saying that it prob does help but until someone has proof or has a sae paper stating that I'm going to trust what I've done and what I've seen. And that happens to be that the cutoff does dick for a performance minded motor. If this wasn't the case you would've seen wear on the older rotaries from the same problem..... Outta all of our race engine(1000rwhp mind you) we have never seen a issue of such.

Last edited by rxspeed7; 04-04-2012 at 02:42 AM.

#79

Release the twins.

HOWEVER, you are right.

it's about idle mix and emissions. with older 13b's you had exhaust/intake over lap from the factory.

Second and Third Generation Turbo 13B

IO 32° ATDC

IC 50° ABDC

EO 71° BBDC

EC 48° ATDC

for 16° I and E are both open. AND THEN people ported them too have huge amounts of overlap.

we're adding peri exhaust, and therefor overlap.

it would be interesting to see the amount of over lap that is produce'd be using rx7 rotors in a Renesis without the gas control rings, or the effect on power/drivability, and then have the exact same rotors machined to make the over lap back down to O°. then re-dyno.

EDIT: after eye balling the above diagram... i would say the amount of overlap by time(degrees) is quite high, anytime the export is exposed to the side of the rotor while the intake is OPEN. BUT the amount of clearance between the housing and rotor(less then 1 mm, I hypothesize) is very small, so it's open to EGR for a lot of time, but by a very small area. dyno's before and after would tell you what that overlap means. but that's not for THIS thread.

Last edited by lastphaseofthis; 04-04-2012 at 05:06 PM.

#80

Thanks for the info.

#82

Release the twins.

lets order some parts of the rotor from compression chamber to the shaft. Cmon, OD you can say them with me!

The bathtub--HOTTT+++

The apex seals/side seals HOTT++

the area between the side seals and "cut off" seal HOT

the "cut off" seal hot

Oil control rings medium, just doing their job

gear, cool enough when kept properly lubed

Bearings, ditto.

so now i ask you, what the **** are you thinking? the "cut off" seal does none of what you posted. go back and re read the paper :D... goof.

Last edited by lastphaseofthis; 04-05-2012 at 11:57 AM.

#84

Registered

iTrader: (3)

conduction--thats what I was thinking. The oil scrapper could interfereswith the oil cooling because the scrapper ring doesnt get as cool as the metal it replaced would? Just a thought...dont get your blood pressure up dude, my thoughts are not worth it. The proxiemity of the side seals to the combustion chamber etc is the real problem with them--i know.

The oil scrapper has been reported as causing increased wear on the irons in relation to the rx7 rotors. That has been observed.

emissions stuff---blah.

again sorry for the highjack--no more of this from me.

The oil scrapper has been reported as causing increased wear on the irons in relation to the rx7 rotors. That has been observed.

emissions stuff---blah.

again sorry for the highjack--no more of this from me.

#93

Registered

I like the idea of the pp exhaust  .. Now did Goppy do a thermal expansion on that pp exhaust slug?

.. Now did Goppy do a thermal expansion on that pp exhaust slug?

If not, hope you did heat those up to least 1800F degrees and check it with a straight edge?

If aluminum slugs ? you will get mad expansion unless its lower siting on the housing and not flush with the chrome on the face/housing.

Hope it helps Eliot..

Thanks

Chip U

.. Now did Goppy do a thermal expansion on that pp exhaust slug?

.. Now did Goppy do a thermal expansion on that pp exhaust slug? If not, hope you did heat those up to least 1800F degrees and check it with a straight edge?

If aluminum slugs ? you will get mad expansion unless its lower siting on the housing and not flush with the chrome on the face/housing.

Hope it helps Eliot..

Thanks

Chip U

#94

Gold Wheels FTW

iTrader: (1)

I like the idea of the pp exhaust  .. Now did Goppy do a thermal expansion on that pp exhaust slug?

.. Now did Goppy do a thermal expansion on that pp exhaust slug?

If not, hope you did heat those up to least 1800F degrees and check it with a straight edge?

If aluminum slugs ? you will get mad expansion unless its lower siting on the housing and not flush with the chrome on the face/housing.

Hope it helps Eliot..

Thanks

Chip U

.. Now did Goppy do a thermal expansion on that pp exhaust slug?

.. Now did Goppy do a thermal expansion on that pp exhaust slug? If not, hope you did heat those up to least 1800F degrees and check it with a straight edge?

If aluminum slugs ? you will get mad expansion unless its lower siting on the housing and not flush with the chrome on the face/housing.

Hope it helps Eliot..

Thanks

Chip U

Hypereutectic Aluminum expands at similar rates to iron/steel. It's essentially what all modern aluminum pistons are made from.

#95

Registered

i'm just brain farting over here...

...

...

#96

FULLY SEMI AUTOMATIC

iTrader: (9)

I like the idea of the pp exhaust  .. Now did Goppy do a thermal expansion on that pp exhaust slug?

.. Now did Goppy do a thermal expansion on that pp exhaust slug?

If not, hope you did heat those up to least 1800F degrees and check it with a straight edge?

If aluminum slugs ? you will get mad expansion unless its lower siting on the housing and not flush with the chrome on the face/housing.

Hope it helps Eliot..

Thanks

Chip U

.. Now did Goppy do a thermal expansion on that pp exhaust slug?

.. Now did Goppy do a thermal expansion on that pp exhaust slug? If not, hope you did heat those up to least 1800F degrees and check it with a straight edge?

If aluminum slugs ? you will get mad expansion unless its lower siting on the housing and not flush with the chrome on the face/housing.

Hope it helps Eliot..

Thanks

Chip U

#100

Boostin'

Thread Starter

We assembled the engine, and cut the flange. A coolant compression test yielded a leak. We are waiting for some time to tear the engine apart, and fix it. Will probably make a jig from now on to bench test..