Possible New Upgrade for Greddy Turbo?

#102

Registered

iTrader: (3)

the 04 and 05's I believe used to have a small restrictor in the heater core line. Many took this thing out thinking it had to do with the marbles in a can sound some heard. The turbo may end up in a sense replacing the restrictor and therefore making the heater better?

The return heater hose does go back to the cold side on the thermostat housing.

The return heater hose does go back to the cold side on the thermostat housing.

#104

Good info about the cooling system and where to get the feed for the turbo.

Jeff, Did you get my email about the Manifold Flange? I sent it to you at jeff@mazdamaniac.com

Now I'm exploring my options with a totally different setup, talking to my fabricator now.

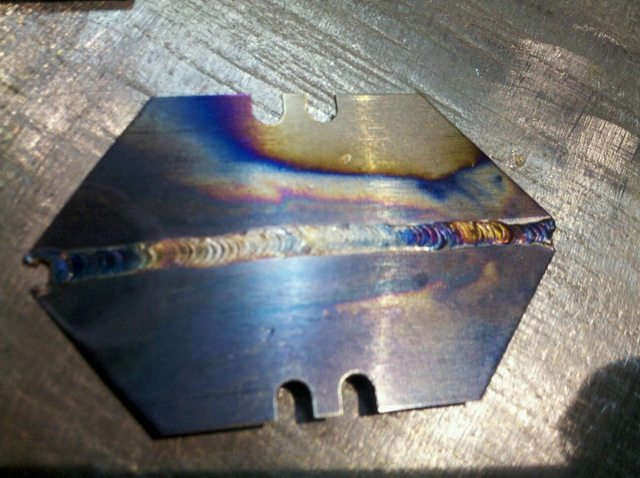

Here's an example of his work:

Yes that's two razor blades tig welded together.

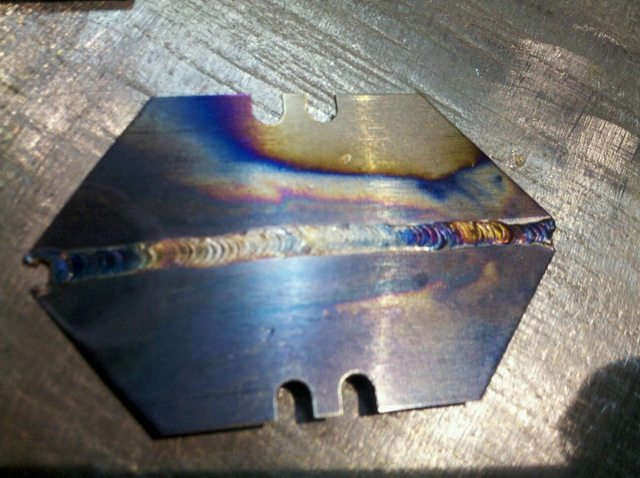

Here's another pic:

Jeff, Did you get my email about the Manifold Flange? I sent it to you at jeff@mazdamaniac.com

Now I'm exploring my options with a totally different setup, talking to my fabricator now.

Here's an example of his work:

Yes that's two razor blades tig welded together.

Here's another pic:

Last edited by kma5783; 02-13-2012 at 02:47 PM.

#113

No respecter of malarkey

iTrader: (25)

Then stop saying stupid things, actually read the white-papers you post, get out the TIG and actually build something, test it and see what happens and - taking a tip from some of your proteges - stop trying to reinvent the wheel from the perspective that it is a device that causes the earth to move under the cart.

The paper is generic at best and they can't take into account all variations of engines and plumbing setups with regard to how effectively they may thermal siphon or not. Yes, I never built a damn thing in my life or proved out any theories. Nearly all the parts for my car magically appeared under my pillow nightly and those same elves keep my car running so well all on their own. Credibility has always been your strong suit.

Speaking of which, you can't even give LuxLuc the luxury of an email let alone deliver a turbo kit to him over three years later yet you are arrogant enough to challenge my resources and capabilities as compared to your own. It must really break your heart to be running around the track while the guy you personally stiffed over for so many years just sits on his hands and wonders wtf is going on with his full payment sent way back then.

You are not the lead designer for an F1 team. You are a broken down nobody in Phoenix trying to pass himself off as somebody on a dying breed car forum full of people who don't know any better because it's your only option. What a joke.

.

Last edited by TeamRX8; 02-13-2012 at 05:50 PM.

#116

Opinions on the following:

According to this article(http://www.davidenglish.com/swift/Te...ld_design.html), using a Mild Steel Flange with Stainless Steel runners would be a better option.

Edit: I haven't read this book personally(yet) but supposedly Corky Bell agrees with the above in his book "Maximum Boost"

Mild Steel

Due to its low degree to thermal expansion, Mild steel is an excellent choice for flanges. Stainless steel, although stronger and more corrosion resistant, is known to expand under heat and rip off the bolts or studs holding the exhaust system together. However, its resilience to high temperatures and corrosion are hardly those of higher-grade steels, and is generally a poor choice for the runners of a manifold.

Stainless Steel

Stainless steel offers excellent corrosion and high temperature properties, and while not appropriate for flanges is a great choice for runners. 321 stainless steel’s coefficient of thermal conductivity is nearly 1/14th that of mild steel’s, significantly reducing heat loss.

Due to its low degree to thermal expansion, Mild steel is an excellent choice for flanges. Stainless steel, although stronger and more corrosion resistant, is known to expand under heat and rip off the bolts or studs holding the exhaust system together. However, its resilience to high temperatures and corrosion are hardly those of higher-grade steels, and is generally a poor choice for the runners of a manifold.

Stainless Steel

Stainless steel offers excellent corrosion and high temperature properties, and while not appropriate for flanges is a great choice for runners. 321 stainless steel’s coefficient of thermal conductivity is nearly 1/14th that of mild steel’s, significantly reducing heat loss.

Edit: I haven't read this book personally(yet) but supposedly Corky Bell agrees with the above in his book "Maximum Boost"

Last edited by kma5783; 02-13-2012 at 06:29 PM.

#118

Huh? Are referring to your post about using the Racing Beat Mild Steel Flange? I know you said you've had no problems with it, but I'm curious to know which is more optimal and to understand why, which is why I'm taking the time to do the research on it.

From what I've read Mild steel is less susceptible to thermal expansion than stainless steel making it a better choice for an exhaust manifold flange.

From what I've read Mild steel is less susceptible to thermal expansion than stainless steel making it a better choice for an exhaust manifold flange.

#120

Yeah,(no insult was intended) your smart your doing research, and have a great welder, so your setup should be great!!

I was on a budget so the mild steel flange had its benifits already stated, and about half the cost.

I was on a budget so the mild steel flange had its benifits already stated, and about half the cost.

#121

I'm assuming using the 1/2" thick stainless flange you would be less likely to have this issue, but I've read that Stainless will expand more to the point of snapping off studs and bolts, definitely not and issue I would want to have. Do you use the factory torque specs when tightening down your manifold? As I would think this would have an effect on the possibility of the studs snapping. Also are you using the factory studs or maybe something with a higher tensile strength?

Pretty good post on the Pros and Cons of Mild Steel and Stainless Steel:

http://mbworld.org/forums/w211-amg/4...ess-steel.html

Yeah if I move forward with the custom build it should be nice, but I have an Esmeril and Greddy kit sitting in my house right now that would need to go first lol.

#123

Also, here's some other good info I've come across about thermal expansion.

So if we take this info and apply it to a manifold flange 1/2" thick with a change in temperature of 1600 degrees(approx. temp of renesis exhaust)

Mild Steel

.0000063 x 0.5" x 1600 = .00504

Stainless Steel

.0000094 x 0.5" x 1600 = .00752

.00752 - .00504 = .00248" difference in expansion of stainless and mild steel in our application

I really think this claim of snapping exhaust manifold studs due solely to thermal expansion of stainless steel is completely over exaggerated.

COTE = Coefficient of Thermal Expansion

For mild steel the COTE is: 6.3 X 10-6

For stainless steel, the COTE is: 9.4 X 10-6

So, to calculate the change in length we use the following formula:

=(COTE)(Length of component)(change in temperature)

Looking at an exhaust system that is 84 inches long, and whose temperature will change 600 degrees F, on average,

For mild steel, change in length=.3157 inch.

For stainless steel, change in length =.473 inch

As you can see, the difference over a 7-foot long exhaust system is negligible (it amounts to .0019 inch per inch).

For mild steel the COTE is: 6.3 X 10-6

For stainless steel, the COTE is: 9.4 X 10-6

So, to calculate the change in length we use the following formula:

=(COTE)(Length of component)(change in temperature)

Looking at an exhaust system that is 84 inches long, and whose temperature will change 600 degrees F, on average,

For mild steel, change in length=.3157 inch.

For stainless steel, change in length =.473 inch

As you can see, the difference over a 7-foot long exhaust system is negligible (it amounts to .0019 inch per inch).

Mild Steel

.0000063 x 0.5" x 1600 = .00504

Stainless Steel

.0000094 x 0.5" x 1600 = .00752

.00752 - .00504 = .00248" difference in expansion of stainless and mild steel in our application

I really think this claim of snapping exhaust manifold studs due solely to thermal expansion of stainless steel is completely over exaggerated.

#124

No respecter of malarkey

iTrader: (25)

Welcome to the real world ... where the studs get just as hot and grow/stretch too

a low mount fully supports the turbo weight @ 1800 degF

16 Ga only use T321 = $$$ and hard to find tight radius fittings

Sch 10 minimum for T304

I would personally recommend T304 Sch 40 as the runs will be short and the total weight is not that much for the amount of built-like-a-brick-sh1th0use durability, you want to keep velocity high, and tight radius turns are readily available for pipe which you will need to avoid a fubar Greddy style manifold. 1.5" Sch 40 T304 = 1.9" OD x 1.62" ID x 1.5R or 2.25"R

a low mount fully supports the turbo weight @ 1800 degF

16 Ga only use T321 = $$$ and hard to find tight radius fittings

Sch 10 minimum for T304

I would personally recommend T304 Sch 40 as the runs will be short and the total weight is not that much for the amount of built-like-a-brick-sh1th0use durability, you want to keep velocity high, and tight radius turns are readily available for pipe which you will need to avoid a fubar Greddy style manifold. 1.5" Sch 40 T304 = 1.9" OD x 1.62" ID x 1.5R or 2.25"R

#125

No respecter of malarkey

iTrader: (25)

if your power goal is reasonable you could also consider using 1.25" Sch pipe. It will help you get around in the limited space better, as will a TiAl turbine housing which is really small and much easier to pipe for. You can essentially have better than upgrade Greddy turbo type performance out of something equivalent to the new GTX 2867R, which at PR=2 flows out to around 44#/min at the far outer reach - which unless you are road racing you will never stay out there for long stretches any way. With a decent high velocity manifold you will have on demand zip instantly available at your toe tips ...

.

.

Last edited by TeamRX8; 02-24-2012 at 05:21 PM.