Lower Compression Rotors for the REnesis

#1

Administrator

Thread Starter

Lower Compression Rotors for the REnesis

Denny decided to delete his thread . he had apparently had enough but we didnt get to anything meaningful and certainly never got to my point. SO here we go.

caveat before we got to far- for the folks who tried to explain things to me you still never got my point so Ill make it clear.

What's your goal OD?

also before we go further lets get this straight with a nice quote from some folks who make motorcycles go 200mph at Bonneville its been said lots here(Kane ahem) before but still it seems to be lost at times

this matters as well

now read this article http://www.musclemustangfastfords.co...o_results.html and tell me what your take away is.

ill be back later im taking my boys to see Santa.

caveat before we got to far- for the folks who tried to explain things to me you still never got my point so Ill make it clear.

What's your goal OD?

also before we go further lets get this straight with a nice quote from some folks who make motorcycles go 200mph at Bonneville its been said lots here(Kane ahem) before but still it seems to be lost at times

Keep in mind that it is airflow that we are concerned about and that RB Racing Turbochargers are designed to move large volumes of air at low boost levels. Do not confuse boost with airflow...it is CFM that makes the torque and power, not pressure alone.

There are a myriad of considerations and experience will beat unproven theorems time after time. A bit of forethought and knowledge never hurt your chances, however.

ill be back later im taking my boys to see Santa.

#9

I divide by zero

Join Date: Aug 2007

Location: Spring Hill, FL

Posts: 1,192

Likes: 0

Received 0 Likes

on

0 Posts

Are we talking for a street car? The thing with low compression is that is hurts your power when not in boost. And while it allows you to run more boost its a trade off since you HAVE to run more boost to make up for the lost compression. So...it gives you different compressor options..and thats about it. Unless you are building a drag car and shooting for HUGE numbers I really dont see the point. I'd rather daily drive a car with Xhp at 11.5:1 than that same power level at 9:1.

Sure low compression gives you margin for error in the tune...sortof. But if you need margin for error in a high HP car you need to have someone else tune and/or you are too close to the edge anyway :P

Sure low compression gives you margin for error in the tune...sortof. But if you need margin for error in a high HP car you need to have someone else tune and/or you are too close to the edge anyway :P

#12

the example with the supercharger doesn't say if they changed the boost with the high compression engine.

Now as I have said before I really am not sure how to go about thinking about this and none of what I say is fact, just speculation, however after thinking for a while I rationalized OD's argument as such...

whereas a high compression low boost engine makes its power over the entire curve by being more efficient over the entire RPM range; a low compression high boost engine is less efficient over the curve but makes up for it by reaching the same working compression at full boost by forcing more air than the LB/HC example. So the HB/LC make more peak power because it flows more air at full boost.

so in short one engine uses high static compression to reach its working compression (tourqe output), whereas the other uses more air to reach the same, the added air is more flow at the same RPM, therefore more HP; basically the static compression is lowered so more air can be forced in the engine at the same working compression (read working temperatures). But for the same amount of flow on both engines, the high compression engine will out produce the low in all conditions, granted you can raise the octane of your fuel to that point.

Now I am sure someone more knowlegeable will tell me why I am wrong!

Now as I have said before I really am not sure how to go about thinking about this and none of what I say is fact, just speculation, however after thinking for a while I rationalized OD's argument as such...

whereas a high compression low boost engine makes its power over the entire curve by being more efficient over the entire RPM range; a low compression high boost engine is less efficient over the curve but makes up for it by reaching the same working compression at full boost by forcing more air than the LB/HC example. So the HB/LC make more peak power because it flows more air at full boost.

so in short one engine uses high static compression to reach its working compression (tourqe output), whereas the other uses more air to reach the same, the added air is more flow at the same RPM, therefore more HP; basically the static compression is lowered so more air can be forced in the engine at the same working compression (read working temperatures). But for the same amount of flow on both engines, the high compression engine will out produce the low in all conditions, granted you can raise the octane of your fuel to that point.

Now I am sure someone more knowlegeable will tell me why I am wrong!

Last edited by WingleBeast; 12-19-2010 at 07:03 PM.

#13

Registered

iTrader: (3)

hope your little guys enjoyed Santa Zoom. I remember those days.

I enjoyed the article and this one statement kinda stood out for me

"Attempting to combine a high static compression ratio and elevated boost levels is a dangerous affair on pump gas." That says part of what I am thinking also.

Now my goal in power is about 300hp to the wheels.

would it be best for the engine to do this with the 10:1 cr we have and around 10 lbs of boost making the final comp ratio of around 16.8?

Or a 9:1 cr engine with boost of approx 12 and a final comp ration of approx 16.3?

Now I am thinking that since I do not run wide open all the time a lower compression ratio engine that runs cooler during normal daily driving would be less stress on the seals and bearings, would be less prone to detonation due to gas octane issues and would have a wider range of tolerance.

Now I do road track--and the rpm range I use should be in the power band that I am used too even with a slightly lower compression engine. I do realize that during normal driving the power level would change some--but hey that is OK with me.

I dont see a downside to this , but then again only one person is doing this that I know of.

He has told me his is doing well.

I do plan on continued use of my w/m system--not tune with it, only use it to reduce charge temps.

I enjoyed the article and this one statement kinda stood out for me

"Attempting to combine a high static compression ratio and elevated boost levels is a dangerous affair on pump gas." That says part of what I am thinking also.

Now my goal in power is about 300hp to the wheels.

would it be best for the engine to do this with the 10:1 cr we have and around 10 lbs of boost making the final comp ratio of around 16.8?

Or a 9:1 cr engine with boost of approx 12 and a final comp ration of approx 16.3?

Now I am thinking that since I do not run wide open all the time a lower compression ratio engine that runs cooler during normal daily driving would be less stress on the seals and bearings, would be less prone to detonation due to gas octane issues and would have a wider range of tolerance.

Now I do road track--and the rpm range I use should be in the power band that I am used too even with a slightly lower compression engine. I do realize that during normal driving the power level would change some--but hey that is OK with me.

I dont see a downside to this , but then again only one person is doing this that I know of.

He has told me his is doing well.

I do plan on continued use of my w/m system--not tune with it, only use it to reduce charge temps.

Last edited by olddragger; 12-19-2010 at 07:30 PM.

#16

There's a reason why, if you examine engines that have turbo and nonturbo versions from the factory, the turbo version inevitably has lower compression. It adds reliability and the loss of response from lower compression rotors can be effectively mitigated by turbo selection and manifold design. All the literature from Mazda points to this.

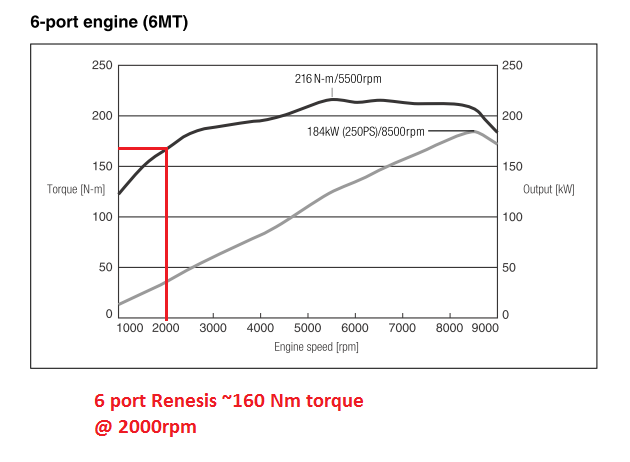

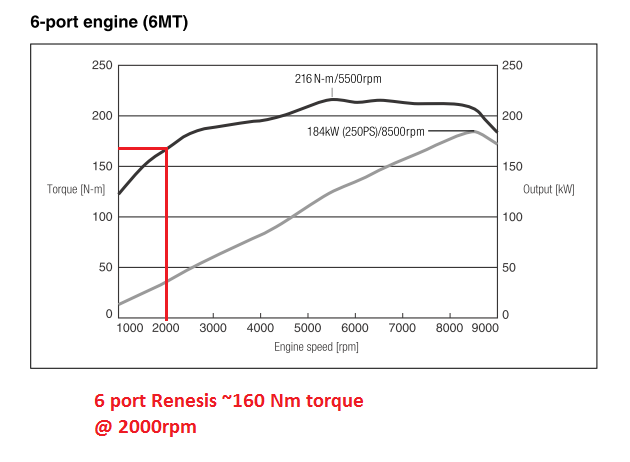

Let's compare torque curves from different rotary engines according to dyno tests from Mazda engineers. First, look at the torque curve of the 6 port JDM Renesis:

160 newton meters @ 2000rpm with 10:1 compression

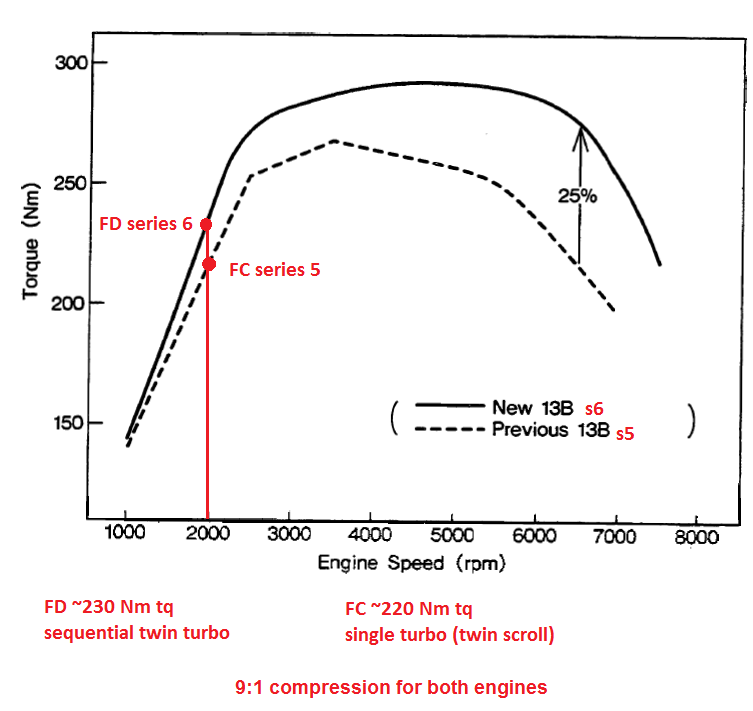

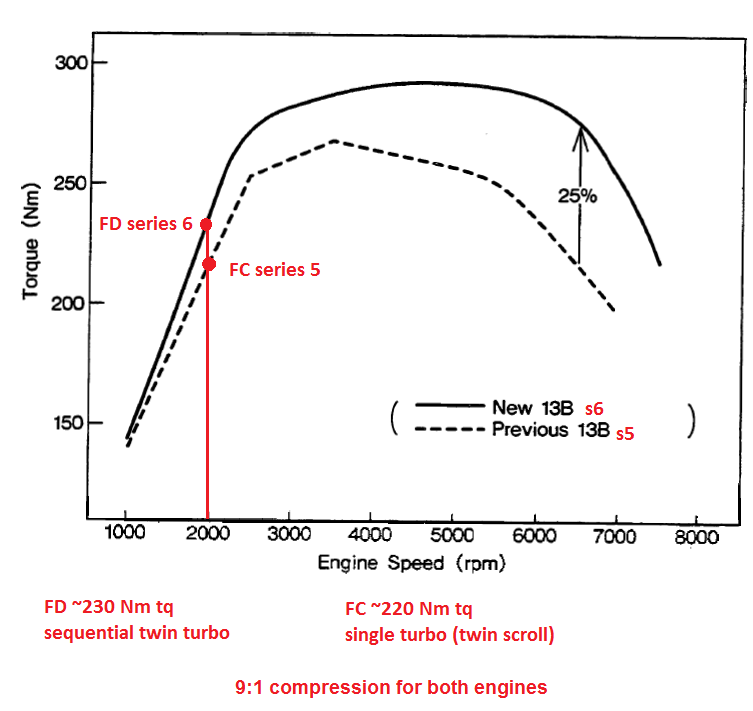

now look at the torque curves from Mazda's turbo engines with 9:1 compression. Here's the series 6 (92-95) FD and the series 5 FC (89-91).

You can see that at 2000rpm the FC engine, which is nominally rated at way less peak power than the Renesis, makes 60 more Nm torque at 2000rpm. The FD makes 70 more torque at 2000rpm. Now look at the 20B:

It's basically a V8-like torque curve, with 9:1 compression. Mazda achieved that by using a narrow-runner exhaust manifold (20B also has 3 exhaust manifold runners like a Renesis). Just because high compression is better on paper doesn't mean it is the practical solution.

There are a bunch of manufacturer dyno plots I can show from piston engines that show the same thing: if engineered properly, low compression means better knock resistance but it does not mean there will be no low end torque. Now gasoline direct injection piston engines are another category as they can run higher compression safely due to the cooling effects of the direct injection.

Let's compare torque curves from different rotary engines according to dyno tests from Mazda engineers. First, look at the torque curve of the 6 port JDM Renesis:

160 newton meters @ 2000rpm with 10:1 compression

now look at the torque curves from Mazda's turbo engines with 9:1 compression. Here's the series 6 (92-95) FD and the series 5 FC (89-91).

You can see that at 2000rpm the FC engine, which is nominally rated at way less peak power than the Renesis, makes 60 more Nm torque at 2000rpm. The FD makes 70 more torque at 2000rpm. Now look at the 20B:

It's basically a V8-like torque curve, with 9:1 compression. Mazda achieved that by using a narrow-runner exhaust manifold (20B also has 3 exhaust manifold runners like a Renesis). Just because high compression is better on paper doesn't mean it is the practical solution.

There are a bunch of manufacturer dyno plots I can show from piston engines that show the same thing: if engineered properly, low compression means better knock resistance but it does not mean there will be no low end torque. Now gasoline direct injection piston engines are another category as they can run higher compression safely due to the cooling effects of the direct injection.

#17

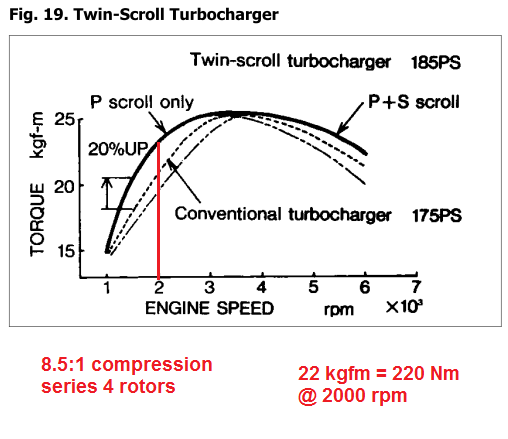

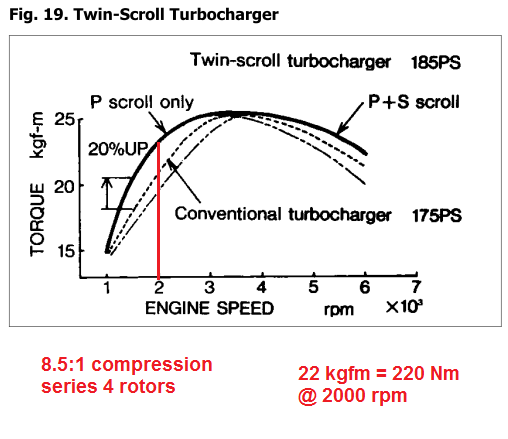

Even with 8.5:1 rotors Mazda still managed about 220 Nm torque at 2000rpm on the series 4 turbo engines, which had a variable A/R system on the turbine housing. This engine only ran around 6psi boost and had no factory electronic boost controller like the later engines. It also ran on 87 octane.

Mazda switched to 9:1 compression on later engines because they had better rotor manufacturing techniques and smarter knock control systems. There are so many more factors involved than compression ratio.

Mazda switched to 9:1 compression on later engines because they had better rotor manufacturing techniques and smarter knock control systems. There are so many more factors involved than compression ratio.

#18

The Stink w.o The Sause

iTrader: (5)

the example with the supercharger doesn't say if they changed the boost with the high compression engine.

Now as I have said before I really am not sure how to go about thinking about this and none of what I say is fact, just speculation, however after thinking for a while I rationalized OD's argument as such...

whereas a high compression low boost engine makes its power over the entire curve by being more efficient over the entire RPM range; a low compression high boost engine is less efficient over the curve but makes up for it by reaching the same working compression at full boost by forcing more air than the LB/HC example. So the HB/LC make more peak power because it flows more air at full boost.

so in short one engine uses high static compression to reach its working compression (tourqe output), whereas the other uses more air to reach the same, the added air is more flow at the same RPM, therefore more HP; basically the static compression is lowered so more air can be forced in the engine at the same working compression (read working temperatures). But for the same amount of flow on both engines, the high compression engine will out produce the low in all conditions, granted you can raise the octane of your fuel to that point.

Now I am sure someone more knowlegeable will tell me why I am wrong!

Now as I have said before I really am not sure how to go about thinking about this and none of what I say is fact, just speculation, however after thinking for a while I rationalized OD's argument as such...

whereas a high compression low boost engine makes its power over the entire curve by being more efficient over the entire RPM range; a low compression high boost engine is less efficient over the curve but makes up for it by reaching the same working compression at full boost by forcing more air than the LB/HC example. So the HB/LC make more peak power because it flows more air at full boost.

so in short one engine uses high static compression to reach its working compression (tourqe output), whereas the other uses more air to reach the same, the added air is more flow at the same RPM, therefore more HP; basically the static compression is lowered so more air can be forced in the engine at the same working compression (read working temperatures). But for the same amount of flow on both engines, the high compression engine will out produce the low in all conditions, granted you can raise the octane of your fuel to that point.

Now I am sure someone more knowlegeable will tell me why I am wrong!

#20

Administrator

Thread Starter

Ok good. Now - arggh and Inspired actually touched on this , Ray and Kane too in your other thread- what fuel do you have available normally? what are you most often going to fill your tank with?

I dont see a downside to this , but then again only one person is doing this that I know of.

#22

Banned

iTrader: (3)

W/M (in concentrations where the alcohol is not contributing fuel value) is a detonation suppressant. Introducing it into a scenario where detonation is not immanent simply reduces power by quenching combustion. This, in turn, raises EGT which is detrimental to the overall health of the motor.

If you do not run sufficiently high enough boost pressures or ignition timing where the suppressant action of the W/M is negating the high flame front speed caused by excessive MEP, all you are doing is losing power and damaging components.

There are several supercharger users here that are employing W/M as a charge cooler which is not only ill-advised but also a fair indicator that the forced-induction device is not operating at or near a useful efficiency range for the application.

There are many superior charge-cooling schemes that do not reduce net power while removing detonation-inducing heat from the intake air.

Last edited by MazdaManiac; 12-20-2010 at 01:57 AM.

#23

Registered

iTrader: (3)

I run pump gas--high test which in the south east is 93 octane plus 10% ethanol. I try to find pure gas when I can--it does make a difference.

I pre mix at 1/2 oz per gallon for the street and 1 oz per gallon for track. Pre mix does affect octane by a small degree.

I do disagree with MM post on w/m injection an no intercooler out there can get charge temps below ambient.

I may be mistaken but I think MM advocates the use of a richer fuel mix as a detonation suppressant?

I pre mix at 1/2 oz per gallon for the street and 1 oz per gallon for track. Pre mix does affect octane by a small degree.

I do disagree with MM post on w/m injection an no intercooler out there can get charge temps below ambient.

I may be mistaken but I think MM advocates the use of a richer fuel mix as a detonation suppressant?

#24

Illudium Q-36 Space Moderator

iTrader: (1)

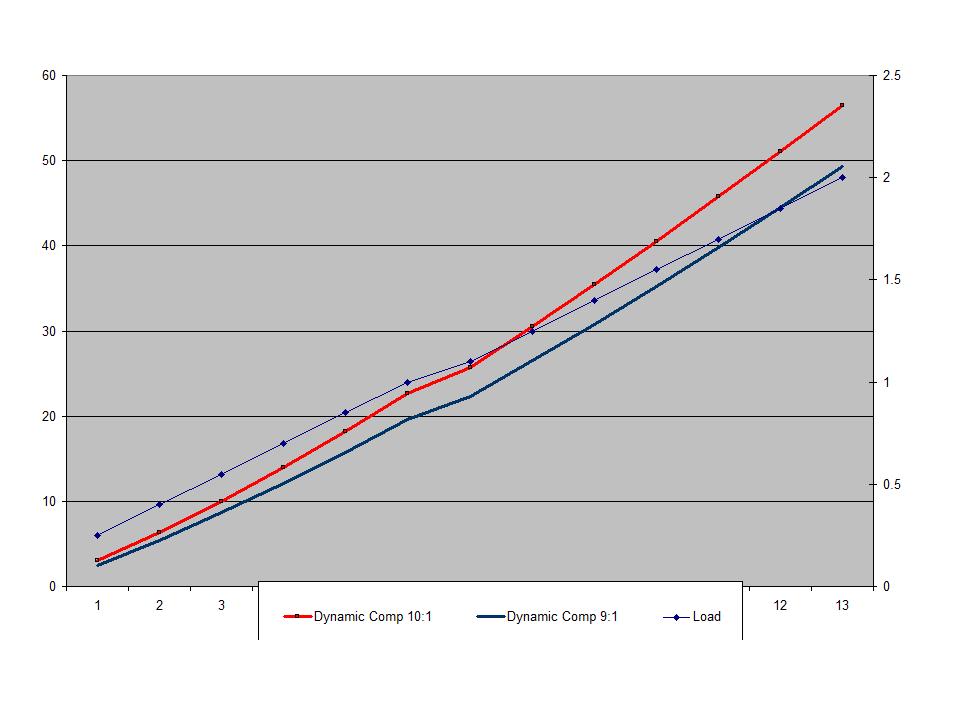

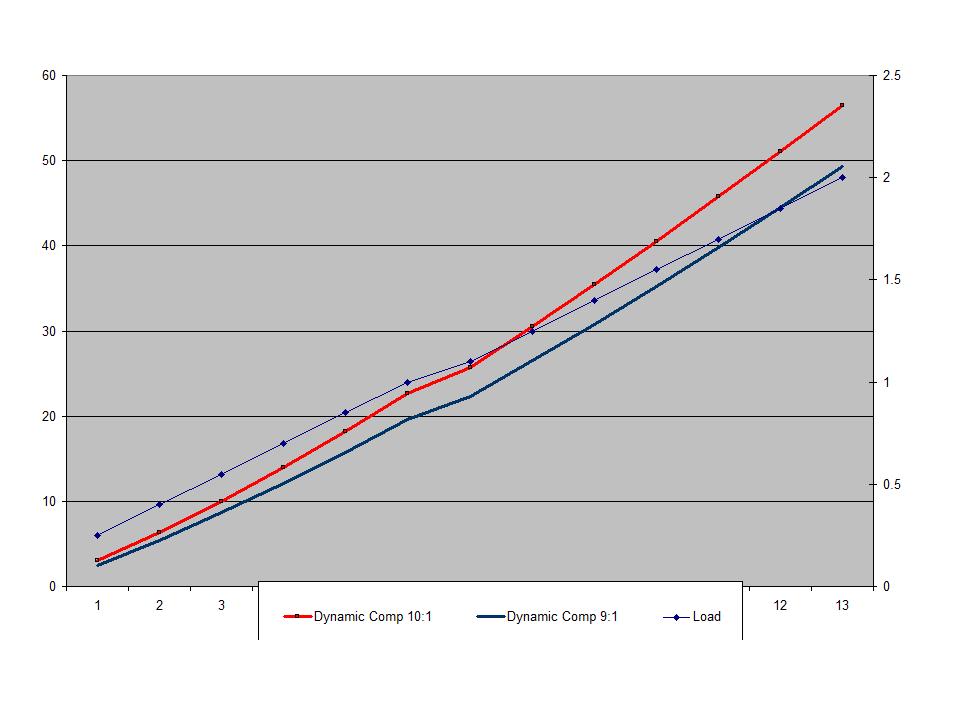

Since I had this math going anyway...

What I was trying to say earlier about efficiency of compressors.

When your compressor (turbo or blower), is more efficient than your engine, it makes sense to use it MORE, IE lower compression. Otherwise, it is counter productive.

Notice the difference in thermal output based on load of a 9:1 and a 10:1 engine, the power output is fairly constant in the 10:! engines favor (duh), but it begins to lose the edge as load increases. The difference in latent heating is in an ideal world, when you factor in efficiency of the engine is gets way steeper - so as load increases, the dynamic compression and latent heat production in the 10:1 compression engine goes up much faster than the 9:1 - and hence at loads in excess of 2 or so, the efficiency of a good compressor can actually overcome the power difference between the two engines. All of this only works in the area where the compressor is operating more efficiently than the engine. Also, a positive displacement compressor is fairly thermally inefficient.....and guess what kind of compressor an engine is?

So, you need to A) have an efficient compressor and B) increase the load by quite a bit to overcome the heat disadvantages of the 10:1 engine. And then, you can only enjoy the advantage when the compressor is producing that high engine load.

What I was trying to say earlier about efficiency of compressors.

When your compressor (turbo or blower), is more efficient than your engine, it makes sense to use it MORE, IE lower compression. Otherwise, it is counter productive.

Notice the difference in thermal output based on load of a 9:1 and a 10:1 engine, the power output is fairly constant in the 10:! engines favor (duh), but it begins to lose the edge as load increases. The difference in latent heating is in an ideal world, when you factor in efficiency of the engine is gets way steeper - so as load increases, the dynamic compression and latent heat production in the 10:1 compression engine goes up much faster than the 9:1 - and hence at loads in excess of 2 or so, the efficiency of a good compressor can actually overcome the power difference between the two engines. All of this only works in the area where the compressor is operating more efficiently than the engine. Also, a positive displacement compressor is fairly thermally inefficient.....and guess what kind of compressor an engine is?

So, you need to A) have an efficient compressor and B) increase the load by quite a bit to overcome the heat disadvantages of the 10:1 engine. And then, you can only enjoy the advantage when the compressor is producing that high engine load.