Stock Greddy turbo compressor flow

#1

Stock Greddy turbo compressor flow

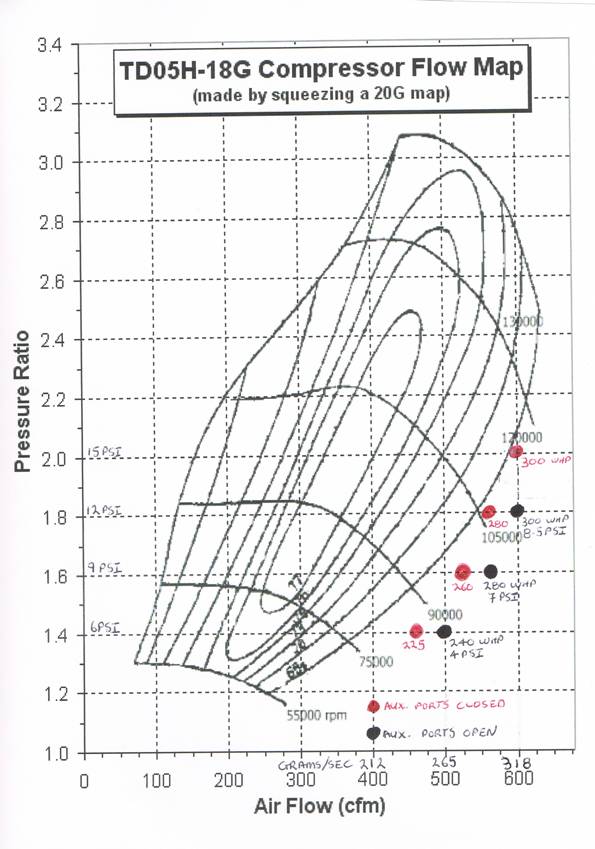

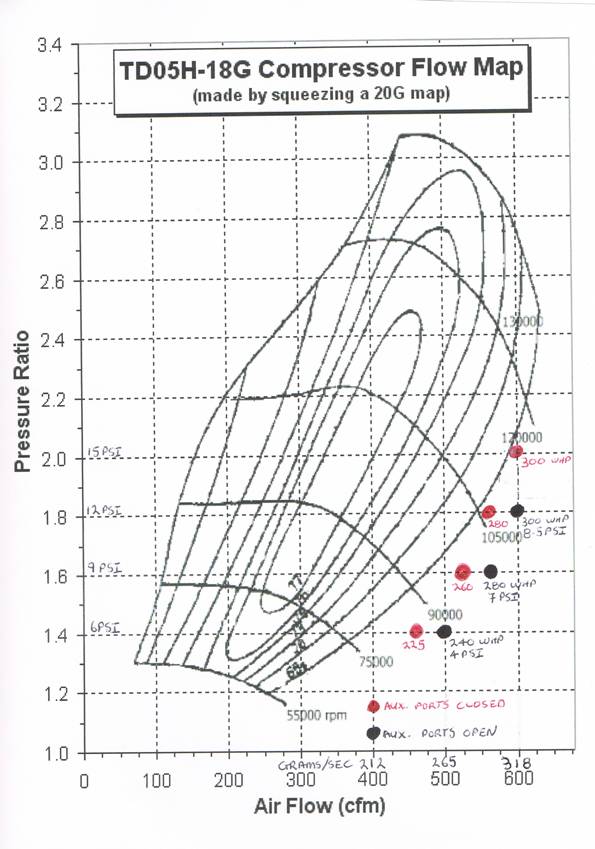

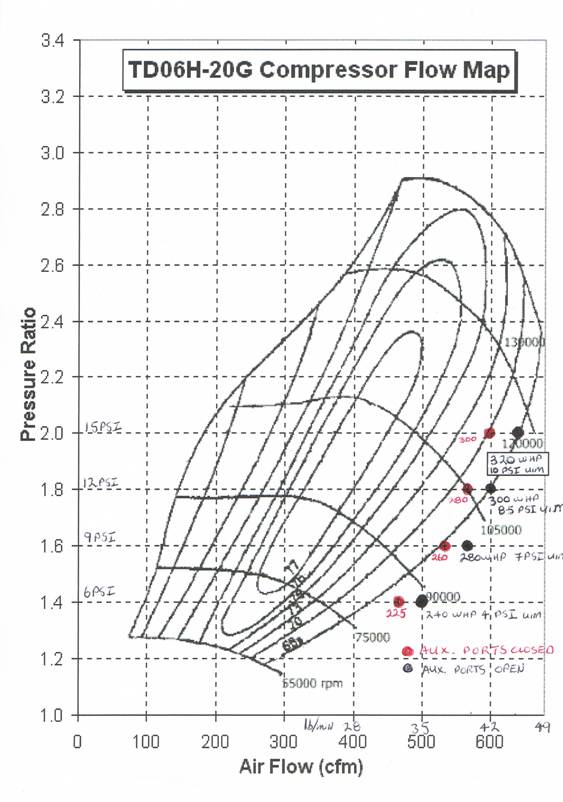

I managed to find this flow chart for the 18G greddy turbo (Compressor Inducer 50.5mm Exducer 68mm) that comes with the Greddy kit for the RX8 . The chart references the TD05H housing which is smaller than the TD06H that comes with the kit but the numbers should be roughly the same.

.

I have attempted to place on the chart what air flow we see in our engines at various WHP (at 7000rpm onwards) with the standard greddy kit pipework in place.

.

This chart illustrates what many of us already knew about the turbo .

EG :

*The compressor is too small for the engine

*Even at low boost the compressor runs way outside its efficiency island therefore making a lot of hot air.

*Running the engine as a 4 port (ie blocking off the aux ports)will improve the efficiency of the compressor at all boost levels.Making the compressor a much better fit for the engine.

.

.

What the chart does illustrate also is that , as you increase the boost the turbo eases closer towards running efficiently but that there is no boost pressure (at high RPM) that you can run that allows the turbo to operate within its design efficiency range.

Flame suit ready .

.

I have attempted to place on the chart what air flow we see in our engines at various WHP (at 7000rpm onwards) with the standard greddy kit pipework in place.

.

This chart illustrates what many of us already knew about the turbo .

EG :

*The compressor is too small for the engine

*Even at low boost the compressor runs way outside its efficiency island therefore making a lot of hot air.

*Running the engine as a 4 port (ie blocking off the aux ports)will improve the efficiency of the compressor at all boost levels.Making the compressor a much better fit for the engine.

.

.

What the chart does illustrate also is that , as you increase the boost the turbo eases closer towards running efficiently but that there is no boost pressure (at high RPM) that you can run that allows the turbo to operate within its design efficiency range.

Flame suit ready .

Last edited by Brettus; 08-31-2014 at 11:23 PM.

#3

Registered

iTrader: (2)

Join Date: Sep 2008

Location: Melbourne, Australia

Posts: 184

Likes: 0

Received 0 Likes

on

0 Posts

you mentioned in one of the other threads that you found the correct 20g compressor flow map online, would be good to post for comparison.

possibly also BNR 57 trim and 60-1 upgrades?

possibly also BNR 57 trim and 60-1 upgrades?

#4

What kind of efficiency numbers lies on the right side of the map is unknown to me

So question is, what consumes less turbine power and creates lower discharge temperatures at same mass flow in this very example - higher PR with higher efficiency number or lower PR with unknown efficiency number?

So question is, what consumes less turbine power and creates lower discharge temperatures at same mass flow in this very example - higher PR with higher efficiency number or lower PR with unknown efficiency number?

#8

/\

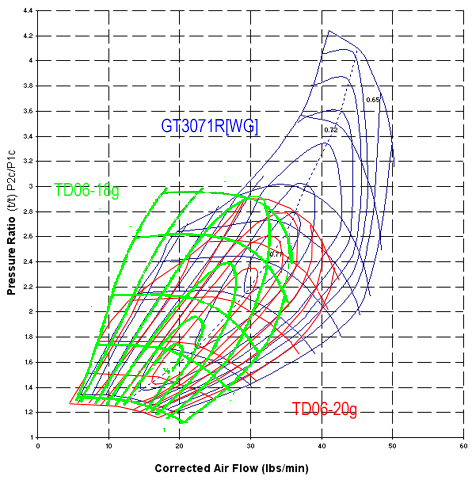

Yes - I have been referencing that comparison chart myself for some time .

However it always bugged me that the chart you posted didn't seem to make any sense whatsoever when comparing it to what happens in reality .

EG : Greddy turbos making 270+WHP regularly and one example making 293whp .

At 36lbs/min which is the limit of flow for the green chart you posted - 250whp should be the absolute maximum whp - yet ...it's not .

After doing some searching around I found 20g and 18g charts that actually make some sense when measured against real life performance .

I believe the chart i posted above is correct and your one ..... not .

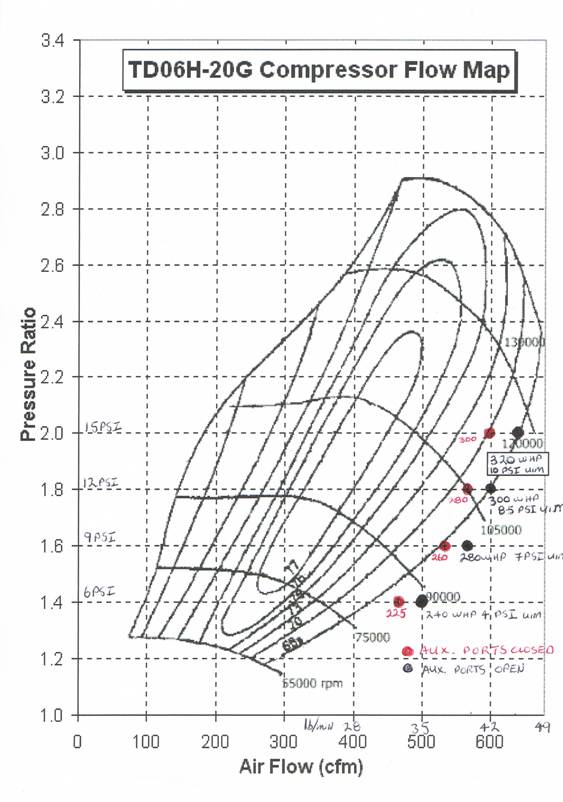

Here is the TD06 20g chart that is plastered all over the net for reference - nothing like your one .

The one i posted is a TD05-18g . The compressor wheel is identical but the TD05 is actually a smaller housing . So if anything it should flow MORE in a TD06 housing . Yet your chart shows it flowing significantly LESS !

Yes - I have been referencing that comparison chart myself for some time .

However it always bugged me that the chart you posted didn't seem to make any sense whatsoever when comparing it to what happens in reality .

EG : Greddy turbos making 270+WHP regularly and one example making 293whp .

At 36lbs/min which is the limit of flow for the green chart you posted - 250whp should be the absolute maximum whp - yet ...it's not .

After doing some searching around I found 20g and 18g charts that actually make some sense when measured against real life performance .

I believe the chart i posted above is correct and your one ..... not .

Here is the TD06 20g chart that is plastered all over the net for reference - nothing like your one .

The one i posted is a TD05-18g . The compressor wheel is identical but the TD05 is actually a smaller housing . So if anything it should flow MORE in a TD06 housing . Yet your chart shows it flowing significantly LESS !

Last edited by Brettus; 11-21-2011 at 10:02 PM.

#10

Tell you what .....

If you can provide any scrap of evidence that your chart is in fact correct for either the 18g or the 20g (and my two charts are not) I challenge you to post it here .

#11

and 5 psi loss at 320 .

If there were other people making that sort of power and measuring this stuff out there ,other than myself, I'm sure they would see the same result with this kit.

A friend has a two gauge set-up . One on the uim and another at the turbo . Pressure drop early in the rpms is almost non existent . Past 6000 one gauge goes down the other goes up . Interesting to watch in real time .

If there were other people making that sort of power and measuring this stuff out there ,other than myself, I'm sure they would see the same result with this kit.

A friend has a two gauge set-up . One on the uim and another at the turbo . Pressure drop early in the rpms is almost non existent . Past 6000 one gauge goes down the other goes up . Interesting to watch in real time .

#13

PSI goes up at the turbo as the resistance to flow increases and the UIM gauge goes down .

It's a happy coincidence that the extra resistance from the restrictive pipework seems to actually be helping us in this scenario . As the PR increases, the efficiency of the turbo is getting significantly better.

It also helps to explain why so very few people have made good power with an upgraded turbo . The resistance to flow must have an effect on the turbine side also , making the actuator ineffective , as pressure behind the turbine/wastegate increases.

It's a happy coincidence that the extra resistance from the restrictive pipework seems to actually be helping us in this scenario . As the PR increases, the efficiency of the turbo is getting significantly better.

It also helps to explain why so very few people have made good power with an upgraded turbo . The resistance to flow must have an effect on the turbine side also , making the actuator ineffective , as pressure behind the turbine/wastegate increases.

Last edited by Brettus; 11-23-2011 at 11:56 AM.

#14

Banned

iTrader: (3)

Do you even say this stuff again in your head before you post it?

Does the idea that total flow is a system make sense to you?

The resistance increases? How? It is a fixed volume (if you forget about the increasing volume from the added flow paths).

The UIM gauge goes down? Why? You just said the "resistance" increases. Why would the pressure drop?

What? So, if the flow decreases (as a result of some sort of increasing resistance, despite an increase in compressor efficiency from a higher Pr) on the cold side it increases on the inlet of the turbine? So, now the cold side is driving the hot side?!? I'm pretty sure that isn't how a turbo works.

Does the idea that total flow is a system make sense to you?

The UIM gauge goes down? Why? You just said the "resistance" increases. Why would the pressure drop?

What? So, if the flow decreases (as a result of some sort of increasing resistance, despite an increase in compressor efficiency from a higher Pr) on the cold side it increases on the inlet of the turbine? So, now the cold side is driving the hot side?!? I'm pretty sure that isn't how a turbo works.

#15

yes

Resistance to flow increases as flow increases - that is pretty fundamental .

It only becomes a fixed volume at about 7000 rpm (in my case). At that point the turbo gauge appears to stabilise somewhat while the uim gauge gradually drops away as rpms climb.

As for why it drops - I think It is because volume flow (from 7000rpm) is static while rpms are climbing . Therefore the engines ability to consume the available air increases . But am not 100% sure , how about you explain that one for us ?

What? So, if the flow decreases (as a result of some sort of increasing resistance, despite an increase in compressor efficiency from a higher Pr) on the cold side it increases on the inlet of the turbine? So, now the cold side is driving the hot side?!? I'm pretty sure that isn't how a turbo works

..

..

You know damn well what I'm trying to say here - and that garbled pile of words is not it !

Last edited by Brettus; 11-24-2011 at 03:46 AM.

#16

Banned

iTrader: (3)

Attempt and succeed are not the same thing. Don't flatter yourself.

I think this is the fundamental misunderstanding you have. (And it has been systemic since the beginning of your attempts to misdirect everyone about flow.)

Resistance does NOT increase as flow increases. It remains the same. It is a fixed value.

If flow increases, then pressure must increase if resistance to flow remains the same (i.e. the path doesn't physically change).

You are trying to invent a fourth variable. There is just volume, pressure and temperature. These are the components of mass flow. (Well, really, density, velocity and area. But, since area is fixed, velocity converts to pressure and you are left with density, which is a function of temperature. This whole relationship between velocity and area is also one of your fundamental misunderstandings, re your previous attempts at obfuscating the discussion about volute.)

If you are seeing a decrease in the manifold pressure, it isn't because the "resistance" is increasing, it is because mass flow is decreasing at a greater rate than the Ve of the motor.

Mass flow decreases because pressure decreases or temperature increases.

That's all there is to it.

The whole system is part of the volute. Changes in area convert velocity into pressure. The compressor efficiency is only part of the total efficiency calculation.

Uh, you are forgetting about time. Remember, RPM is a description of an event over time.

"Total flow" through the engine is fixed, but modulated by velocity, which is where Ve comes from.

Resistance does NOT increase as flow increases. It remains the same. It is a fixed value.

If flow increases, then pressure must increase if resistance to flow remains the same (i.e. the path doesn't physically change).

You are trying to invent a fourth variable. There is just volume, pressure and temperature. These are the components of mass flow. (Well, really, density, velocity and area. But, since area is fixed, velocity converts to pressure and you are left with density, which is a function of temperature. This whole relationship between velocity and area is also one of your fundamental misunderstandings, re your previous attempts at obfuscating the discussion about volute.)

If you are seeing a decrease in the manifold pressure, it isn't because the "resistance" is increasing, it is because mass flow is decreasing at a greater rate than the Ve of the motor.

Mass flow decreases because pressure decreases or temperature increases.

That's all there is to it.

The whole system is part of the volute. Changes in area convert velocity into pressure. The compressor efficiency is only part of the total efficiency calculation.

"Total flow" through the engine is fixed, but modulated by velocity, which is where Ve comes from.

Last edited by MazdaManiac; 11-24-2011 at 10:03 AM.

#18

That pressure vs flow argument was all about you trying to educate the unwashed masses and putting me in my place . You never actually attempted to understand the angle I was coming from .

In fact - I know for certain if you could move outside of your current paradigm , that you would be a better tuner than you already are - at least in the field of diagnoses .

Resistance does NOT increase as flow increases. It remains the same. It is a fixed value.

If flow increases, then pressure must increase if resistance to flow remains the same (i.e. the path doesn't physically change).

You are trying to invent a fourth variable. There is just volume, pressure and temperature. These are the components of mass flow. (Well, really, density, velocity and area. But, since area is fixed, velocity converts to pressure and you are left with density, which is a function of temperature. This whole relationship between velocity and area is also one of your fundamental misunderstandings, re your previous attempts at obfuscating the discussion about volute.)

.

So no - i'm not trying to introduce another variable - it's just semantics .

If you are seeing a decrease in the manifold pressure, it isn't because the "resistance" is increasing, it is because mass flow is decreasing at a greater rate than the Ve of the motor.

Mass flow decreases because pressure decreases or temperature increases.

That's all there is to it.

.

Mass flow decreases because pressure decreases or temperature increases.

That's all there is to it.

.

Secondly : I didn't say the decrease in manifold pressure was because resistance was increasing . Re-read my previous post .

Thirdly : my explanation for why pressure goes down and flow stays the same actually makes some sense - see if you can come up with a better one .

Well that certainly is another way to look at it but it kinda feels like you just came up with that so you could make a counterpoint .

#19

I think i got what MM and Brettus means.

Here's my criterias, forgive me for any ignorance;

- Resistance is mostly given by intercooler, right?

- Flow is not turbulent(laminar in english?).

What Maniac means regarding flow resistance

As long as flow is not turbulent, flow resistance will be a certain factor for all flows, meaning that if you have 5psi drop @200g/s, you will have 10psi@400g/s. Pressure drop = factor * flow. By that resistance is fixed, not increasing. It is flow that is increasing.

What Brettus means

To keep a certain pressure AFTER intercooler, you need to increase pressure from turbo to compensate. At a higher pressure you get a better efficiency.

Or have I got it totally wrong? Trying hard to educate myself regarding turbo, but feel like progress rate is like pulling barbwire out of my ***....

Here's my criterias, forgive me for any ignorance;

- Resistance is mostly given by intercooler, right?

- Flow is not turbulent(laminar in english?).

What Maniac means regarding flow resistance

As long as flow is not turbulent, flow resistance will be a certain factor for all flows, meaning that if you have 5psi drop @200g/s, you will have 10psi@400g/s. Pressure drop = factor * flow. By that resistance is fixed, not increasing. It is flow that is increasing.

What Brettus means

To keep a certain pressure AFTER intercooler, you need to increase pressure from turbo to compensate. At a higher pressure you get a better efficiency.

Or have I got it totally wrong? Trying hard to educate myself regarding turbo, but feel like progress rate is like pulling barbwire out of my ***....

#20

Banned

iTrader: (3)

No, I'm sure that is not what you mean. So, it is NOT "semantics". It is physics.

What you are observing is pressure decreasing because flow is increasing while the temperature remains constant OR pressure decreasing because temperature is decreasing while the flow remains constant.

Obviously, the latter is the least likely - even if the turbo is becoming more efficient, the lower temperature will be offset by the increased flow.

So, pressure is decreasing in the manifold because engine demand is increasing faster then compressor output. Total system flow is decreasing as a function of time (RPM).

The MAF is showing increasing input flow, but this is below demand, so pressure decreases.

In a system where compressor efficiency meets demand, this will not happen.

So - enlighten me.

Where have my "diagnoses" failed me?

So far, all you have done is try to force-fit improperly correlated data points into equally malformed conclusions.

This would be somewhat understandable if the proper correlations and conclusions weren't already extant.

But they are and evidenced in abundance.

Last edited by MazdaManiac; 11-26-2011 at 08:28 AM.

#21

Yet you too are getting confused …

PSI goes up at the turbo as the resistance to flow increases and the UIM gauge goes down .

And it was you who said “pressure is resistance to flow” not me . That statement is not strictly true but I knew what you were getting at and ran with it , so you turning that around on me is kinda ironic.

So, pressure is decreasing in the manifold because engine demand is increasing faster then compressor output. Total system flow is decreasing as a function of time (RPM).

The MAF is showing increasing input flow, but this is below demand, so pressure decreases.

In a system where compressor efficiency meets demand, this will not happen.

.

The MAF is showing increasing input flow, but this is below demand, so pressure decreases.

In a system where compressor efficiency meets demand, this will not happen.

.

I am continually adding to my repertoire.

So - enlighten me.

Where have my "diagnoses" failed me?

So far, all you have done is try to force-fit improperly correlated data points into equally malformed conclusions.

This would be somewhat understandable if the proper correlations and conclusions weren't already extant.

But they are and evidenced in abundance.

How ? By recognizing that pressure is a useful parameter for comparison purposes.

Yet You constantly berate me for insisting that pressure is useful .

#22

Banned

iTrader: (3)

No, but you not understanding this principle is fundamental.

As flow through the system increases, pressure will decrease if temperature remains constant.

So, now you are agreeing with the very premise you were disagreeing with in the previous admonishment?

I haven't had any cars with "**** poor" results that weren't mechanicals.

I don't really offer diagnostic services at dyno events. There isn't the time and I don't think the customer - or those that are waiting - would like to go through the time or expense that such diagnostics would require.

I am quite happy to have people like you that do that for others free of charge.

I simply do not have the luxury of being so charitable.

As flow through the system increases, pressure will decrease if temperature remains constant.

So, now you are agreeing with the very premise you were disagreeing with in the previous admonishment?

I don't really offer diagnostic services at dyno events. There isn't the time and I don't think the customer - or those that are waiting - would like to go through the time or expense that such diagnostics would require.

I am quite happy to have people like you that do that for others free of charge.

I simply do not have the luxury of being so charitable.

#23

At the turbo ( rpm past 7000): we see

pressure increase

flow is staic

Temperature increase

So the increase in pressure (at the turbo) would best be explained by the fact that the compressor moved over its choke line and became less efficient. Correct ?

Originally Posted by Brettus

As for why it drops - I think It is because volume flow (from 7000rpm) is static while rpms are climbing . Therefore the engines ability to consume the available air increases . But am not 100% sure , how about you explain that one for us ?

I haven't had any cars with "**** poor" results that weren't mechanicals.

I don't really offer diagnostic services at dyno events. There isn't the time and I don't think the customer - or those that are waiting - would like to go through the time or expense that such diagnostics would require.

I am quite happy to have people like you that do that for others free of charge.

I simply do not have the luxury of being so charitable.

I don't really offer diagnostic services at dyno events. There isn't the time and I don't think the customer - or those that are waiting - would like to go through the time or expense that such diagnostics would require.

I am quite happy to have people like you that do that for others free of charge.

I simply do not have the luxury of being so charitable.

I still say you miss a key ingredient by dismissing pressure the way you do.

Last edited by Brettus; 11-27-2011 at 01:25 PM.

#24

Pressure drop is squared function of flow. If you really would have 5 psi drop at 200g/s, it could be 20 psi drop at double flow

If it was true, VE% would have to decrease at the same rate as rpms are increasing, therefore, you would observe same flow and same pressure from that point on - obviously, this is not case.

Maybe you meant actual mass flow? ad:

ad:

Of course it increases, because we know that above isn´t true and VE% decrease happens at lower rate than rpm increase, to the point.

So only reason why your manifold pressure drops while flow remains same is because, as Mazdamaniac already pointed out, compressor can´t keep up with engine demand.

Probably yes. But now you can see that observed pressure is in reality consequence of inefficient operation of overspeeding compressor resulting in high discharge temperatures and it doesn´t aid in system efficiency as you assumed.

Without fast reacting temperature sensor in every place where you´re measuring pressure, its meaningless parameter. So why bother?

Maybe you meant actual mass flow?

ad:

ad:Of course it increases, because we know that above isn´t true and VE% decrease happens at lower rate than rpm increase, to the point.

So only reason why your manifold pressure drops while flow remains same is because, as Mazdamaniac already pointed out, compressor can´t keep up with engine demand.

Without fast reacting temperature sensor in every place where you´re measuring pressure, its meaningless parameter. So why bother?

#25

http://en.wikipedia.org/wiki/Reynolds_Number

http://en.wikipedia.org/wiki/Pressure_drop

I had to check with one of the hydraulic eng at my workplace, and he also said that in an ideal system, pressure drop will be linear. When flow is turbulent it goes exponential. Then, of course, you have factors like what kind of material your tubing is made of etc.