MOP Adjustments

#1

MOP Adjustments

I have always felt that my '8, for whatever reason, consumed way less oil than it should for the kind of driving I engage in. After three different motors (each with a different OMP) and a string of PCM recalibrations, the oil consumption continued to dwindle to the point where, as it stands, my motor consumes no oil at all.

Now, I pre-mix fairly heavily (8 oz pr 14 gal of fuel, about 220:1), so I have been banking heavily on the insurance this provides. However, I was looking to discover a means to get the OMP to deliver more oil than it has been on its own.

I took apart one of the spare OMPs that I have laying around.

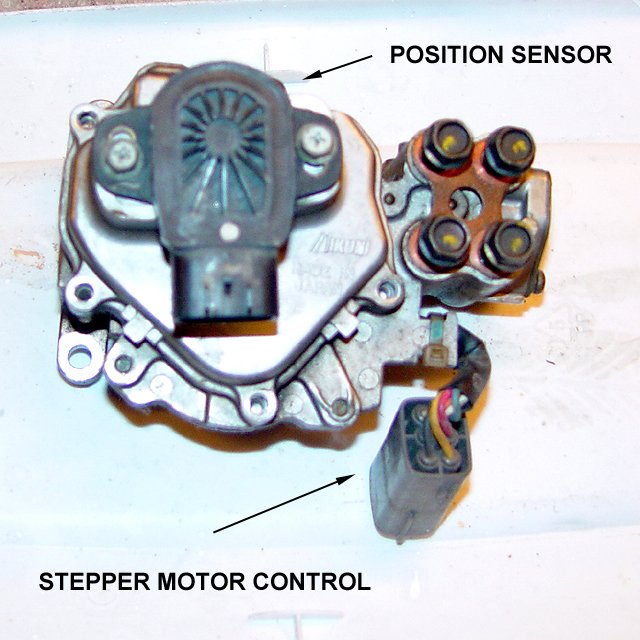

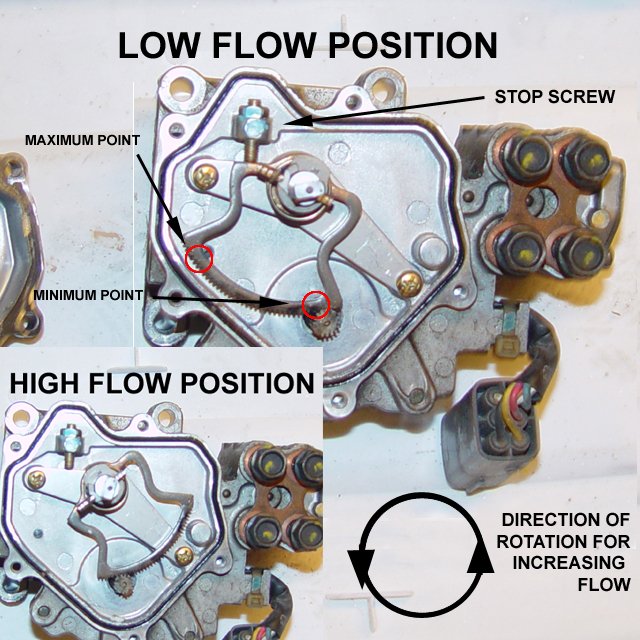

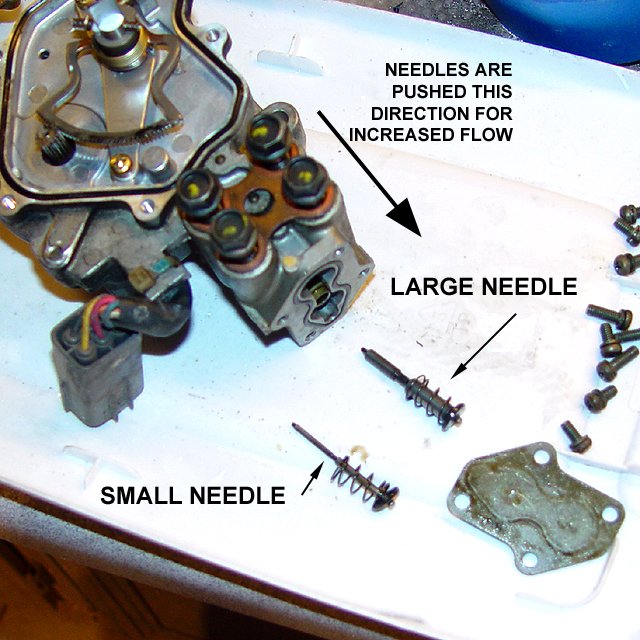

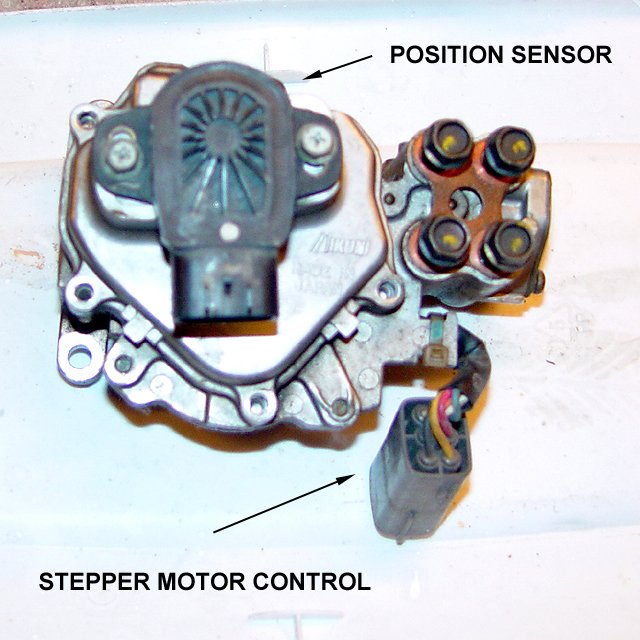

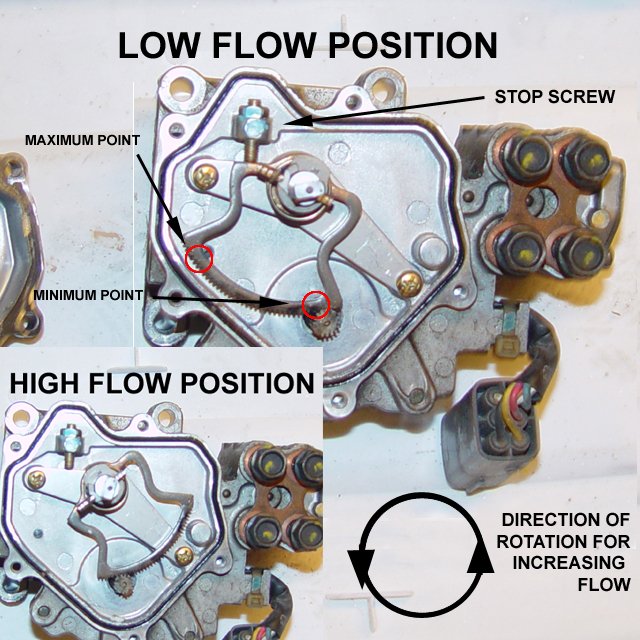

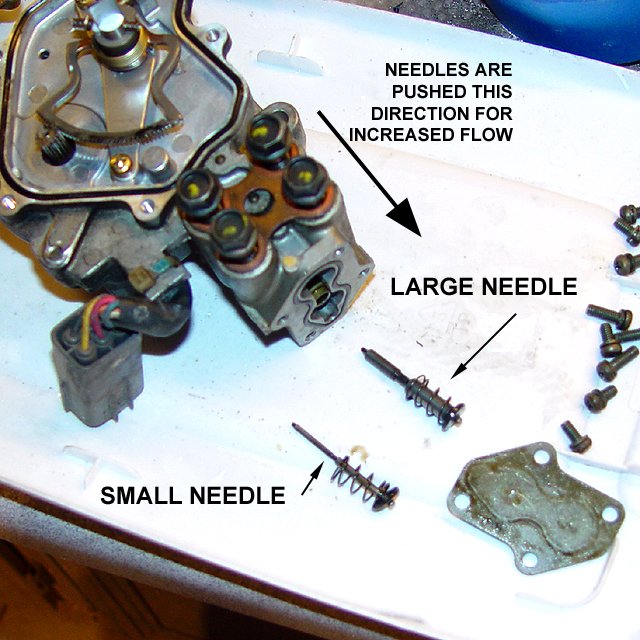

The OMP has a stepper motor that drives a geared cam that is regulated by a position sensor (interestingly enough, it is a throttle position sensor from the KL series of motors used in the MX6/MX-3/626/929/Millennia). When the PCM commands the valve open, it rotates in a counter-clockwise direction in a series of steps that are regulated in a servo motor fashion from minimum to maximum. This rotation turns and internal cam which, in turn, pushes open a set of spring loaded needles which have a "step" machined into them to allow a small amount of oil to get by (under pressure from the engine oil pump) and out to the metering nozzles.

Racing Beat provides a service where they enlarge the notch on one of the metering needles so that, when the needle is in its maximum "out" position, the amount of oil it delivers is greater. The two drawback I see with this are 1) They charge and exorbitant price for this service ($275) and 2) it only affects oil delivery when the OMP is at maximum.

What I am going to experiment with is adjustment of the position sensor.

There is a lot of travel remaining in the "increase" direction (counter-clockwise). It seems to me that by just tweaking the position sensor a hair in that direction, one could increase the flow of the pump somewhat.

Any suggestions are welcome.

Now, I pre-mix fairly heavily (8 oz pr 14 gal of fuel, about 220:1), so I have been banking heavily on the insurance this provides. However, I was looking to discover a means to get the OMP to deliver more oil than it has been on its own.

I took apart one of the spare OMPs that I have laying around.

The OMP has a stepper motor that drives a geared cam that is regulated by a position sensor (interestingly enough, it is a throttle position sensor from the KL series of motors used in the MX6/MX-3/626/929/Millennia). When the PCM commands the valve open, it rotates in a counter-clockwise direction in a series of steps that are regulated in a servo motor fashion from minimum to maximum. This rotation turns and internal cam which, in turn, pushes open a set of spring loaded needles which have a "step" machined into them to allow a small amount of oil to get by (under pressure from the engine oil pump) and out to the metering nozzles.

Racing Beat provides a service where they enlarge the notch on one of the metering needles so that, when the needle is in its maximum "out" position, the amount of oil it delivers is greater. The two drawback I see with this are 1) They charge and exorbitant price for this service ($275) and 2) it only affects oil delivery when the OMP is at maximum.

What I am going to experiment with is adjustment of the position sensor.

There is a lot of travel remaining in the "increase" direction (counter-clockwise). It seems to me that by just tweaking the position sensor a hair in that direction, one could increase the flow of the pump somewhat.

Any suggestions are welcome.

#2

Registered User

Join Date: Mar 2005

Location: south FL

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

I would start with the position sensor first like you suggested.

Like the KL Tb's is there a voltage reading that can be adjusted?

Would different spring rates affect the oil flow, more or less , sooner rather

than later.

And of course the more difficult one would be to have access to a lathe and

machine the pins a couple of thousandths. that is if you knew where on the pin

to machine.

You could put the pins in a dremel and use some sand paper. not as accurate but could also get it done.

Andy P. 93 GS 1.8T

Like the KL Tb's is there a voltage reading that can be adjusted?

Would different spring rates affect the oil flow, more or less , sooner rather

than later.

And of course the more difficult one would be to have access to a lathe and

machine the pins a couple of thousandths. that is if you knew where on the pin

to machine.

You could put the pins in a dremel and use some sand paper. not as accurate but could also get it done.

Andy P. 93 GS 1.8T

#3

From what I read the new flash increases the flow through the OMP.

If that doesn't solve the problem, then how about having RB reprogram it for you?

The set srew adjustment will just affect the oil flow at idle.

The sensor position is just like points right?

Changing that will only effect how fast it reacts, not increase the flow, Right?

Move points closer or farther out. Changes timing not flow.

Look at the needles. They are like motorcyle carbs. We have adjustments to increase flow.

You can create a notch in the needles.

Then you can lower or raise the height. Effectively chaging the flow throughout the whole range.

I think we need to look at the mechanical side and modify the needles.

You can put a notch in it to move the washer on the end to compress the spring more.

This is what I am thinking. Remove that washer on the end and use C clips like on motorcycle carbs. Make two more notches and you have something to play with.

Another way to cheat is to take the needles and regrind them. Make the taper differant. By reducing the thickness and taper you will flow more oil.

What do you think?

If that doesn't solve the problem, then how about having RB reprogram it for you?

The set srew adjustment will just affect the oil flow at idle.

The sensor position is just like points right?

Changing that will only effect how fast it reacts, not increase the flow, Right?

Move points closer or farther out. Changes timing not flow.

Look at the needles. They are like motorcyle carbs. We have adjustments to increase flow.

You can create a notch in the needles.

Then you can lower or raise the height. Effectively chaging the flow throughout the whole range.

I think we need to look at the mechanical side and modify the needles.

You can put a notch in it to move the washer on the end to compress the spring more.

This is what I am thinking. Remove that washer on the end and use C clips like on motorcycle carbs. Make two more notches and you have something to play with.

Another way to cheat is to take the needles and regrind them. Make the taper differant. By reducing the thickness and taper you will flow more oil.

What do you think?

Last edited by Razz1; 06-22-2007 at 10:36 PM.

#4

The position sensor tells the PCM at what position the volume cam is pointed.

Turning the sensor counter-clockwise will tell the PCM that closed is a actually little more open. It will also tell the PCM open is wider than it thinks.

The overall effect is that the range of the cam will be moved up scale. More oil will happen everywhere.

In theory, anyway.

I'm getting under there to adjust my wastegate tonight, so I'll take some scope measurements and twist it open a bit and see what happens.

Turning the sensor counter-clockwise will tell the PCM that closed is a actually little more open. It will also tell the PCM open is wider than it thinks.

The overall effect is that the range of the cam will be moved up scale. More oil will happen everywhere.

In theory, anyway.

I'm getting under there to adjust my wastegate tonight, so I'll take some scope measurements and twist it open a bit and see what happens.

#5

Registered

I don't know anything about this particular stepper or what kind of PWM signal it's receiving, but theoretically speaking, you could put a device between the stepper and stepper controller that altered the PWM signal delivered to the motor itself to drive it to whatever position you wanted.

You'd also have to alter the signal sent back to the controller from the position sensor so it doesn't think that it's too far open. You could keep all of this in a pair of lookup tables.

Of course, adding an electrical device to the loop has its own risks and issues.

You'd also have to alter the signal sent back to the controller from the position sensor so it doesn't think that it's too far open. You could keep all of this in a pair of lookup tables.

Of course, adding an electrical device to the loop has its own risks and issues.

#6

Someone here actually hooked up a second OMP that the PCM controls directly so it stays happy.

Then, you could use a stepper driver to alter the signal and drive the original motor however you wish.

That does add way to much complexity, though.

It think just altering the feedback signal will do the trick.

Then, you could use a stepper driver to alter the signal and drive the original motor however you wish.

That does add way to much complexity, though.

It think just altering the feedback signal will do the trick.

#7

Registered

Someone here actually hooked up a second OMP that the PCM controls directly so it stays happy.

Then, you could use a stepper driver to alter the signal and drive the original motor however you wish.

That does add way to much complexity, though.

It think just altering the feedback signal will do the trick.

Then, you could use a stepper driver to alter the signal and drive the original motor however you wish.

That does add way to much complexity, though.

It think just altering the feedback signal will do the trick.

#9

Got Another Rotary

The position sensor tells the PCM at what position the volume cam is pointed.

Turning the sensor counter-clockwise will tell the PCM that closed is a actually little more open. It will also tell the PCM open is wider than it thinks.

The overall effect is that the range of the cam will be moved up scale. More oil will happen everywhere.

In theory, anyway.

I'm getting under there to adjust my wastegate tonight, so I'll take some scope measurements and twist it open a bit and see what happens.

Turning the sensor counter-clockwise will tell the PCM that closed is a actually little more open. It will also tell the PCM open is wider than it thinks.

The overall effect is that the range of the cam will be moved up scale. More oil will happen everywhere.

In theory, anyway.

I'm getting under there to adjust my wastegate tonight, so I'll take some scope measurements and twist it open a bit and see what happens.

I am going to look at the position sensor rotation as well to get the OMP to flow more throughout the range - great research!

Also, you may have discovered why so many people are running different rates - since the position sensor is adjustable, could be that they are set differently for some people.

#14

Registered User

Join Date: Mar 2005

Location: St. Helens, OR

Posts: 221

Likes: 0

Received 0 Likes

on

0 Posts

How is the calibration done for it? The sensor output would be different for each car, I would think it would move to the hard limit, and 'zero' itself from there.

Or is it like an inhouse factory done thing?

Or is it like an inhouse factory done thing?

#15

Got Another Rotary

Thanks again for the info and ideas MM!.

So today, I adjusted my OMP position sensor as MM suggested. Here are my notes:

- It is easy to loosen the two screws from underneath and adjust the sensor. There appears to be about 30 degrees of movement possible in the counter-clockwise direction (more oil flow) and none in the clockwise direction. I used a 7mm socket instead of a screwdriver as it easier to reach with extensions through the fenderwell this way.

- I first moved the sensor as far counter-clockwise as I could for maximum oil flow - about 30 degrees. Unfortunately, this threw a CEL immediately upon starting the car and put the engine in limp mode as I suspect it took it slightly out of the normal adjustable range.

- So, I disconnected the battery to reset the ECU, and then backed the OMP sensor back (clockwise) about 5, maybe 10 degrees. This time when I started the car, all was well with no CELs. I took a short drive, about 5-10 miles, and it seems to be fine.

Now the fun part is to start monitoring the impact to OMP oil injection to see what the difference is - I an currently using about 1 qt/3000 miles (slightly more miles than I previously thought). I hope this increases the OMP flow significantly - I would like to see 1 qt/1500 miles to reduce my premix need, but we'll see.

I will provide usage data as I collect it.

So today, I adjusted my OMP position sensor as MM suggested. Here are my notes:

- It is easy to loosen the two screws from underneath and adjust the sensor. There appears to be about 30 degrees of movement possible in the counter-clockwise direction (more oil flow) and none in the clockwise direction. I used a 7mm socket instead of a screwdriver as it easier to reach with extensions through the fenderwell this way.

- I first moved the sensor as far counter-clockwise as I could for maximum oil flow - about 30 degrees. Unfortunately, this threw a CEL immediately upon starting the car and put the engine in limp mode as I suspect it took it slightly out of the normal adjustable range.

- So, I disconnected the battery to reset the ECU, and then backed the OMP sensor back (clockwise) about 5, maybe 10 degrees. This time when I started the car, all was well with no CELs. I took a short drive, about 5-10 miles, and it seems to be fine.

Now the fun part is to start monitoring the impact to OMP oil injection to see what the difference is - I an currently using about 1 qt/3000 miles (slightly more miles than I previously thought). I hope this increases the OMP flow significantly - I would like to see 1 qt/1500 miles to reduce my premix need, but we'll see.

I will provide usage data as I collect it.

The following users liked this post:

techexpress (11-07-2022)

#16

Cool.

I'm under my car right now, doing a compression test and a de-carbon technique to measure the impact. I'm also fabbing my oil cooler fan brackets since the fans showed up last week.

I'll probably twiddle my position sensor around 10 degrees or so and see what happens.

You might want to pre-mix during the experiment just in case it doesn't go as planned.

I'm under my car right now, doing a compression test and a de-carbon technique to measure the impact. I'm also fabbing my oil cooler fan brackets since the fans showed up last week.

I'll probably twiddle my position sensor around 10 degrees or so and see what happens.

You might want to pre-mix during the experiment just in case it doesn't go as planned.

#17

Got Another Rotary

I agree with your assessment though on the OMP operation and I don't see how this mod could flow less oil (although anything is possible I guess), but we just don't have any way to really know how much more it will flow with the adjustment as the ECU might pick up this change and just compensate for it (hopefully not though).

#18

- I first moved the sensor as far counter-clockwise as I could for maximum oil flow - about 30 degrees. Unfortunately, this threw a CEL immediately upon starting the car and put the engine in limp mode as I suspect it took it slightly out of the normal adjustable range.

- So, I disconnected the battery to reset the ECU, and then backed the OMP sensor back (clockwise) about 5, maybe 10 degrees. This time when I started the car, all was well with no CELs. I took a short drive, about 5-10 miles, and it seems to be fine.

I will provide usage data as I collect it.

- So, I disconnected the battery to reset the ECU, and then backed the OMP sensor back (clockwise) about 5, maybe 10 degrees. This time when I started the car, all was well with no CELs. I took a short drive, about 5-10 miles, and it seems to be fine.

I will provide usage data as I collect it.

#19

Registered User

Join Date: Mar 2005

Location: St. Helens, OR

Posts: 221

Likes: 0

Received 0 Likes

on

0 Posts

Cool.

I'm under my car right now, doing a compression test and a de-carbon technique to measure the impact. I'm also fabbing my oil cooler fan brackets since the fans showed up last week.

I'll probably twiddle my position sensor around 10 degrees or so and see what happens.

You might want to pre-mix during the experiment just in case it doesn't go as planned.

I'm under my car right now, doing a compression test and a de-carbon technique to measure the impact. I'm also fabbing my oil cooler fan brackets since the fans showed up last week.

I'll probably twiddle my position sensor around 10 degrees or so and see what happens.

You might want to pre-mix during the experiment just in case it doesn't go as planned.

#20

Registered

My electrical schematic shows that the sensor is just a switch. If that is the case then what probably happens is this:

At ignition on, the stepping motor backs off until it hits the minimum stop. It then reverses and counts the steps until the sensor switch changes state. At the factory, the sensor was positioned for X number of steps to the switch. Some allowance is provided in the programming to account for movement in this adjustment as a result of wear, vibration, etc as the vehicle ages. However too far a movement and a flag is raised, i.e. CEL.

My guess is that if the PCM does not get the correct number of steps, and if the error is not too great, then it will simply assume there has been a slight movement of the switch, and do exactly what it did before the switch was moved. That is it will provide the stepping motor with the number of pulses it is programed with to meet the lubrication requirements of the engine. The sensor is just a check that things haven't gone too far astray.

At ignition on, the stepping motor backs off until it hits the minimum stop. It then reverses and counts the steps until the sensor switch changes state. At the factory, the sensor was positioned for X number of steps to the switch. Some allowance is provided in the programming to account for movement in this adjustment as a result of wear, vibration, etc as the vehicle ages. However too far a movement and a flag is raised, i.e. CEL.

My guess is that if the PCM does not get the correct number of steps, and if the error is not too great, then it will simply assume there has been a slight movement of the switch, and do exactly what it did before the switch was moved. That is it will provide the stepping motor with the number of pulses it is programed with to meet the lubrication requirements of the engine. The sensor is just a check that things haven't gone too far astray.

Last edited by Delmeister; 07-03-2007 at 07:32 AM.

The following 2 users liked this post by Delmeister:

Stephen Davies (10-16-2022),

zorzinio (12-30-2022)

#21

Got Another Rotary

My electrical schematic shows that the sensor is just a switch. If that is the case then what probably happens is this:

At ignition on, the stepping motor backs off until it hits the minimum stop. It then reverses and counts the steps until the sensor switch changes state. At the factory, the sensor was positioned for X number of steps to the switch. Some allowance is provided in the programming to account for movement in this adjustment as a result of wear, vibration, etc as the vehicle ages. However too far a movement and a flag is raised, i.e. CEL.

My guess is that if the PCM does not get the correct number of steps, and if the error is not too great, then it will simply assume there has been a slight movement of the switch, and do exactly what it did before the switch was moved. That is it will provide the stepping motor with the number of pulses it is programed with to meet the lubrication requirements of the engine. The sensor is just a check that things haven't gone too far astray.

At ignition on, the stepping motor backs off until it hits the minimum stop. It then reverses and counts the steps until the sensor switch changes state. At the factory, the sensor was positioned for X number of steps to the switch. Some allowance is provided in the programming to account for movement in this adjustment as a result of wear, vibration, etc as the vehicle ages. However too far a movement and a flag is raised, i.e. CEL.

My guess is that if the PCM does not get the correct number of steps, and if the error is not too great, then it will simply assume there has been a slight movement of the switch, and do exactly what it did before the switch was moved. That is it will provide the stepping motor with the number of pulses it is programed with to meet the lubrication requirements of the engine. The sensor is just a check that things haven't gone too far astray.

While this is possible, I am hoping it is not and that the ECU will adjust the base rate setting based on the adjusted position sensor - we'll see.

#22

could it be that your driving results in more blow-by and fuel dilution and making it appear as the oil level never goes down?

in some turbo rx-7's the oil level actually goes up!

in some turbo rx-7's the oil level actually goes up!

#24

the enemy in the mirror

Join Date: Oct 2006

Location: billerica, ma

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

if you were to separate the 'saw arm' from the gear it meshes with, couldn't you turn the gear slightly (and then put the saw arm back in the same position) to pre-load the amount? then it would always be at a higher setting than it used to be (across the range). I'm assuming that simply adjusting the stop screw is not giving enough extra flow (or it can't be moved). The only danger here would be if it tried to move beyond the full flow point and the omp has a bad failure mode in this case (doesn't stop at max & something bad happens).

$.02

this is interesting to follow~

$.02

this is interesting to follow~

#25

Registered

iTrader: (3)

makes sense, would have to be very careful about how much to turn the set screw---IF it is adjustable--which I kinda think it is not. Moving the sensor as stated may be something of interest!! I have one of those cars that doesnt use oil unless i am on the track.

olddragger

olddragger