OMP Oil Metering pump output and modification

#52

77 cylinders, 4 rotors...

Yes, a big job, especially running with oil injectors in place to see what goes on. I wonder if the better builders use injection at all when breaking engines in. They may have some tales to tell as well...

#53

77 cylinders, 4 rotors...

Just ran the pump with a drilled large pump in the small location, and got enough miles to determine new consumption, and it IS greater. I get about 900-950 miles per quart now with a fully completed mod#2 under moderate driving, with a mixture of city and highway. I am personally happy with that consumption level, as my old 12a FB was in a similar range under normal driving conditions also. (800-1000 miles per quart, but with crankcase oil injected) Again this is consumption rate with a Sohn and 2 stroke oil injected.

#55

77 cylinders, 4 rotors...

Yes, greater than with stock unmodified pump, (by a factor of 2+) and greater than with my initial undrilled large pump in small side Mod#2. I was getting about 1200 miles/quart before drilling and about 925 miles/quart now. So Bret, thanks much for the insight on the pump!

No crankcase oil for me anymore! I like 2 stroke. I worked on many 2 strokes in a shop years and years ago, and you could ALWAYS tell when the customer ran regular motor oil instead of 2 stroke oil. It just goes against my grain. I had my old 12a pump apart and was going to modify it to take 2 stroke oil, (in the pre-sohn days of the mid 80s) but never got around to it. I just never liked the idea of crankcase oil burning in the chamber. Especially at very lean mixture rates.

No crankcase oil for me anymore! I like 2 stroke. I worked on many 2 strokes in a shop years and years ago, and you could ALWAYS tell when the customer ran regular motor oil instead of 2 stroke oil. It just goes against my grain. I had my old 12a pump apart and was going to modify it to take 2 stroke oil, (in the pre-sohn days of the mid 80s) but never got around to it. I just never liked the idea of crankcase oil burning in the chamber. Especially at very lean mixture rates.

#56

Yes, greater than with stock unmodified pump, (by a factor of 2+) and greater than with my initial undrilled large pump in small side Mod#2. I was getting about 1200 miles/quart before drilling and about 925 miles/quart now. So Bret, thanks much for the insight on the pump!

.

.

#57

Registered

I'm really leaning toward your way of thinking .

With a stock OMP :

*Street cars that spend very little time in higher rpm/load range wear out the housings very quickly .... I've seen heaps of housings in engines from 50000 miles up to 100,000 miles . The housings are always worn out.

* Race car engines last quite a long time and wear on the housings is minimal after many races .

Conclusion : not enough oil at low load rpm on the smaller pump but sufficient oil for high load/rpm once large pump kicks in.

With a stock OMP :

*Street cars that spend very little time in higher rpm/load range wear out the housings very quickly .... I've seen heaps of housings in engines from 50000 miles up to 100,000 miles . The housings are always worn out.

* Race car engines last quite a long time and wear on the housings is minimal after many races .

Conclusion : not enough oil at low load rpm on the smaller pump but sufficient oil for high load/rpm once large pump kicks in.

This thread needs more input. The lack of more community involvement I believe is due to the lack of understanding of what exactly is going on. To remedy this, it would be appropriate for one or both of your guys to write a technical type document outlining what you know about how this pump works, especially the valving. Your mods also need more explanation particularly with respect to 'drilling', as do your experimental results. I believe then that more people will jump in with fresh ideas on ways to improve oil flow to the injectors. Anyway, thanks to both of you for your commitment to this project.

#59

77 cylinders, 4 rotors...

Delmeister,

Yes! Brettus has done a great job researching this pump and posting the details. I was looking for info like this myself, before I bought my first RX8. Your originial OMP posts were read and re-read by me several times. Unfortunately there is still some mystery to it, even after all these years!

In my opinion, the place to look for most longevity improvements in the Renesis involve emissions. Many compromises were made to meet emissions targets, and then maintain the life of the cat over the state mandated periods. If we look at reversing some of those engineering decisions, lifespan will increase exponentially. Again, I believe this was the first OBDII rotary and as such had many extreme measures taken to meet emissions laws, with lifespan the main loser, and peak power and economy second.

Yes! Brettus has done a great job researching this pump and posting the details. I was looking for info like this myself, before I bought my first RX8. Your originial OMP posts were read and re-read by me several times. Unfortunately there is still some mystery to it, even after all these years!

In my opinion, the place to look for most longevity improvements in the Renesis involve emissions. Many compromises were made to meet emissions targets, and then maintain the life of the cat over the state mandated periods. If we look at reversing some of those engineering decisions, lifespan will increase exponentially. Again, I believe this was the first OBDII rotary and as such had many extreme measures taken to meet emissions laws, with lifespan the main loser, and peak power and economy second.

The following users liked this post:

techexpress (11-08-2022)

#60

Thanks guys . Ironically , I'm not even running the omp anymore as it was getting in the way of my turbo intake. However , I do think the mod #2 with a little tweaking of the ECU map could be the way to go for both street and small turbo setups without any need for premix.

#62

Update : A recent discussion on the Purely site has filled in the gaps for me about a few things .

Firstly , here is a quote from Don Walker , a guy who has raced rx8s extensively . We were discussing how much oil pressure there was supplying the OMP ...

He says he made up a blanking plate specifically to measure this pressure .

Secondly re the Sohn Adapter :

Firstly , here is a quote from Don Walker , a guy who has raced rx8s extensively . We were discussing how much oil pressure there was supplying the OMP ...

I did. We saw idle oil pressure (18-20psi hot at idle and about 40psi at higher rpm. Because of the way the oil feed port is designed it does restrict oil pressure, but if you start the engine with the OMP off it will shoot a laser beam of oil across your shop

Secondly re the Sohn Adapter :

What Brett noticed and what you are theorizing is correct. At low to moderate engine speed and load the gravity feed is just barely enough, but as engine RPM and load increase the gravity feed cannot keep up and not enough oil is injected. What has saved the Sohn guys so far is they are almost entirely street cars and still premix as you yourself stated in the oil thread. It is literally the mantra "Sohn adapter and premix". Well, ok but if you are going to do that save yourself the money and potential failure of the Sohn and just premix

Gary that is why I only ever talk about the results on the track of the Sohn vs standard cars. The Sohn car ate engines (on my competitors car he destroyed an engine every weekend, and at Mid-Ohio he killed an engine every single session he was on track) while the standard car never had an issue. Also the amount of oil used was extremely telling. The sohn used half as much oil at best as did the standard car. You cannot and will not ever convince me the Sohn provides anything but a failure point when it is using 1/8th to a 1/4qt of oil vs a 1/2 or more qt of oil in the same session on the same track in nearly identical cars. And that is the real key. Now yes, we were running the cars hard, shifting at 9400 and the engines rarely dropped below 3k on track, but at a track like St Pete, which is a street course you are going all the way down to 2nd and back up to 5th several times per lap, 10 or 12 laps in a session, so believe this is as close as mere mortals can get to a proper stress test.

The following users liked this post:

kevink0000 (12-06-2018)

#63

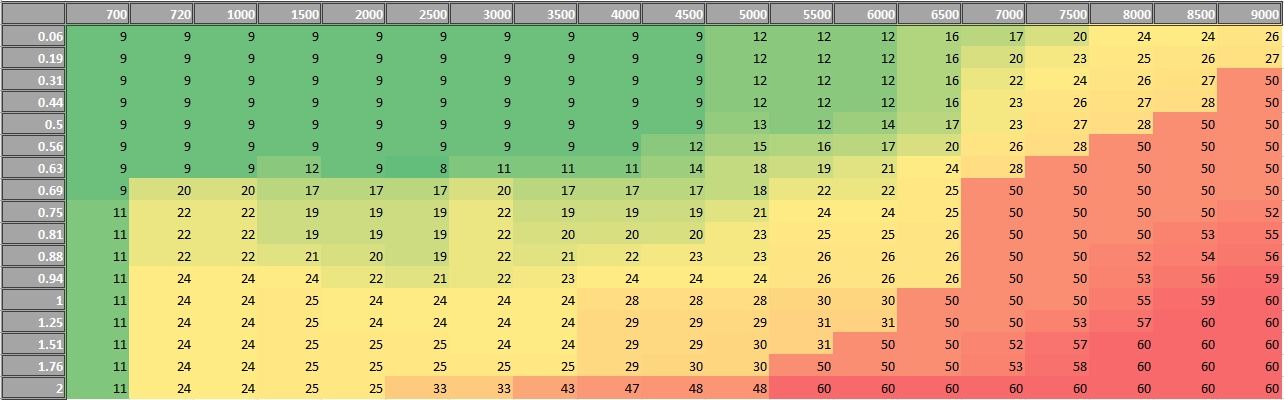

so based on this information, those of us with access to the OMP map can't we just increase it further for low loads and cruising?

I personally have always had the idle and cruise regions higher. now I wonder if I should go more

I personally have always had the idle and cruise regions higher. now I wonder if I should go more

#65

could you make another graph but at 1krpms (idle) and another at 4krpms (cruise)?

also is there much talk about pressure? if there is only about 40psi of pressure and we are boosting say 15psi, doesn't that mean we are getting less oil, due to the effective oil pressure being 25PSI now?

also is there much talk about pressure? if there is only about 40psi of pressure and we are boosting say 15psi, doesn't that mean we are getting less oil, due to the effective oil pressure being 25PSI now?

#67

bassed from your 9k graph there is little to no change from 3-9 on the settings and 21? seems to be when the larger pump begins to flow.

seems like cruising should be 21 at minimum?

seems like cruising should be 21 at minimum?

The following users liked this post:

Brettus (12-04-2018)

#71

77 cylinders, 4 rotors...

Brettus,

Well now we have more to think about with this ^^@#$%^#$% OMP!

So, the info you forwarded is convincing to me, even though it is anecdotal. I think the racer's opinion based on the amount of oil used in race conditions is worthy of note, because output at maximum should not vary much at all, certainly not by a factor of 2 or even 4. That is assuming the injectors themselves are unclogged and functioning properly, which I would assume is something a racer would confirm, especially in light of numerous premature engine failures.

So, assuming the lack of oil seen on the track is from the gravity feed nature of the Sohn, some questions:

Did he get oil pressure from a blockoff block BOTH OMP oil holes in the front cover? From what I can see, the OMP is located in a "stream" of oil, and it has an intake and outlet. One hole on the front cover actually feeds the unit, the other is a drain back into the front cover again. If I remember correctly, the feed hole is the one next to the drive, and the drain hole is the other one farthest from the drive. I could be wrong on this, but my circuit explorations led me to believe this was the most likely layout. Again, I could be wrong! So, there may be 40lbs of max hot oil pressure if "deadheading" both holes, but it would be nice to know if his apparatus had one hole open to the rest of the circuit in the same fashion as the pump, and what pressure the OMP is actually seeing, as a flow through device in the main circuit.

The Sohn tubing itself can easily flow 2lph (your max output calculation at 9k rpm) but the internal diameter of the OMP feed circuits themselves may not. I will use my test stand to see if there is enough leakage through the unit to safely accommodate this amount of oil feed through the pump chambers with just a gravity feed. I suspect this is not the peak output determiner though.

I think out previous conversation about "OMP valve float" may have resurfaced here. If I use your excellent research, I estimate that the big pump in the OMP body strokes at a rate of 14 times a second at max engine rpm. That is mighty fast for that small return spring to keep the pump body on the drive cam in the viscous environment of the OMP internally. It must have "help" in the form of intake head pressure, to bring the pump body back to the cam quickly for the next stoke. This, I feel would be the main obstacle in the OMP giving full output at high rpm with a gravity feed. And why it does OK on the street, or even in some track environments, because it can achieve full output at lower rpm, but begins to float at higher speeds. Just a theory.

I plan to add a small pump to the Sohn intake on my car, maybe 10-15 psi. I will run on the test stand first, just to see how it reacts with the OMP.

I want to keep running it on 2 stroke oil only,(not in the oilpan.) hence the feed pump proposal and I do want to keep the OMP working in conjunction with premix. I am unabashedly in the More Oil Everywhere camp with this engine.

Brettus I know you are premix only, I was wondering whet you thought of Eric Meyer's findings on his race cars regarding side seal spring failure and running the OMP with premix to avoid this. His posts were pretty convincing I thought, and make sense from a practical standpoint. Mazda focused the omp nozzles on the S1 and S2 to the sides for a reason, vs non-Renesis designs.

https://www.rx8club.com/series-i-tec...-210194/page6/

I am open to anybody's input/discussion on this, as I am still trying to fully understand how this thing works.

Well now we have more to think about with this ^^@#$%^#$% OMP!

So, the info you forwarded is convincing to me, even though it is anecdotal. I think the racer's opinion based on the amount of oil used in race conditions is worthy of note, because output at maximum should not vary much at all, certainly not by a factor of 2 or even 4. That is assuming the injectors themselves are unclogged and functioning properly, which I would assume is something a racer would confirm, especially in light of numerous premature engine failures.

So, assuming the lack of oil seen on the track is from the gravity feed nature of the Sohn, some questions:

Did he get oil pressure from a blockoff block BOTH OMP oil holes in the front cover? From what I can see, the OMP is located in a "stream" of oil, and it has an intake and outlet. One hole on the front cover actually feeds the unit, the other is a drain back into the front cover again. If I remember correctly, the feed hole is the one next to the drive, and the drain hole is the other one farthest from the drive. I could be wrong on this, but my circuit explorations led me to believe this was the most likely layout. Again, I could be wrong! So, there may be 40lbs of max hot oil pressure if "deadheading" both holes, but it would be nice to know if his apparatus had one hole open to the rest of the circuit in the same fashion as the pump, and what pressure the OMP is actually seeing, as a flow through device in the main circuit.

The Sohn tubing itself can easily flow 2lph (your max output calculation at 9k rpm) but the internal diameter of the OMP feed circuits themselves may not. I will use my test stand to see if there is enough leakage through the unit to safely accommodate this amount of oil feed through the pump chambers with just a gravity feed. I suspect this is not the peak output determiner though.

I think out previous conversation about "OMP valve float" may have resurfaced here. If I use your excellent research, I estimate that the big pump in the OMP body strokes at a rate of 14 times a second at max engine rpm. That is mighty fast for that small return spring to keep the pump body on the drive cam in the viscous environment of the OMP internally. It must have "help" in the form of intake head pressure, to bring the pump body back to the cam quickly for the next stoke. This, I feel would be the main obstacle in the OMP giving full output at high rpm with a gravity feed. And why it does OK on the street, or even in some track environments, because it can achieve full output at lower rpm, but begins to float at higher speeds. Just a theory.

I plan to add a small pump to the Sohn intake on my car, maybe 10-15 psi. I will run on the test stand first, just to see how it reacts with the OMP.

I want to keep running it on 2 stroke oil only,(not in the oilpan.) hence the feed pump proposal and I do want to keep the OMP working in conjunction with premix. I am unabashedly in the More Oil Everywhere camp with this engine.

Brettus I know you are premix only, I was wondering whet you thought of Eric Meyer's findings on his race cars regarding side seal spring failure and running the OMP with premix to avoid this. His posts were pretty convincing I thought, and make sense from a practical standpoint. Mazda focused the omp nozzles on the S1 and S2 to the sides for a reason, vs non-Renesis designs.

https://www.rx8club.com/series-i-tec...-210194/page6/

I am open to anybody's input/discussion on this, as I am still trying to fully understand how this thing works.

#72

Brettus I know you are premix only, I was wondering whet you thought of Eric Meyer's findings on his race cars regarding side seal spring failure and running the OMP with premix to avoid this. His posts were pretty convincing I thought, and make sense from a practical standpoint. Mazda focused the omp nozzles on the S1 and S2 to the sides for a reason, vs non-Renesis designs.

.

Last edited by Brettus; 12-07-2018 at 02:01 PM.

#73

I'm very surprised this discussion has not yet brought up any of the tests done by this youtuber I found tonight.

Start there and go through his 5 other videos. He tests gravity fed and pressure fed, then tests using one in a vehicle with some interesting results.

The following users liked this post:

kevink0000 (01-01-2019)

#74

77 cylinders, 4 rotors...

Those videos sure are interesting! Thank you for finding those. I wonder if he is a member here. I couldn't quite make out where the pressure measurements were being taken from if somebody knows please chime in.

In other news, I modded the OMP again, based on info in the original OMP thread with Delmeister, MM, etc.

So now we have Mod #3. I kept the larger 2nd pump in place, per Mod#2, and adjusted the sector gear to be at maximum stroke at 60 steps by adjusting the idle stop, and moving the OMP sensor the same amount so it can still count the 60 steps and not throw a code. This moves all settings up as far as the pump is concerned, but the computer is still functioning off the stock map. I had to notch the OMP sensor screw holes to get enough travel to accommodate the change of angle. The OMP sensor has metal inserts in the slot holes, I did not retain those.

Big change of output with this. With my previous Mod#2 only, I was getting about 900-950 miles per quart consumption in normal driving, with a mixture of city/highway, getting about 19.5-20.5 mpg per tankful. With the sector gear mod, and nothing else changing, I am now down to 425 -450 miles per quart consumption with the same driving style. I estimate the sector gear moved about 6-7 teeth with this mod, which I think is equivalent to 12-14 steps of the motor. This mod is adjustable, so if this consumption level is excessive, you can adjust the stop and the sensor, and thereby the working range of the pump to anything you want within reason. Not as easy as a software based solution, but still good to know about, especially if racing or emission test rules only allow stock flashes. So, with only mechanical mods, the OMP can be taken from about 1500 miles per quart to 400 miles per quart in normal driving.

In other news, I modded the OMP again, based on info in the original OMP thread with Delmeister, MM, etc.

So now we have Mod #3. I kept the larger 2nd pump in place, per Mod#2, and adjusted the sector gear to be at maximum stroke at 60 steps by adjusting the idle stop, and moving the OMP sensor the same amount so it can still count the 60 steps and not throw a code. This moves all settings up as far as the pump is concerned, but the computer is still functioning off the stock map. I had to notch the OMP sensor screw holes to get enough travel to accommodate the change of angle. The OMP sensor has metal inserts in the slot holes, I did not retain those.

Big change of output with this. With my previous Mod#2 only, I was getting about 900-950 miles per quart consumption in normal driving, with a mixture of city/highway, getting about 19.5-20.5 mpg per tankful. With the sector gear mod, and nothing else changing, I am now down to 425 -450 miles per quart consumption with the same driving style. I estimate the sector gear moved about 6-7 teeth with this mod, which I think is equivalent to 12-14 steps of the motor. This mod is adjustable, so if this consumption level is excessive, you can adjust the stop and the sensor, and thereby the working range of the pump to anything you want within reason. Not as easy as a software based solution, but still good to know about, especially if racing or emission test rules only allow stock flashes. So, with only mechanical mods, the OMP can be taken from about 1500 miles per quart to 400 miles per quart in normal driving.

The following users liked this post:

SiNfidelity (07-24-2022)

#75

I tapped into the cover plate which is between the two oil galleys in the OMP, basically dead center of the OMP itself.

I used an M6 1.0 adapter that I happened to find in my garage as part of a harbor freight fuel pressure test kit.

If anyone is interested in using the adapter plate for thier own testing, perhaps with electronic sensors that are more sensitive on the order of a few psi, let me know!

The plate was very hard and brittle and I couldn't drill it so I resorted to punching a hole in it with a screwdriver. Cracks propagated outward but were later contained completely by the welding of the M6 1.0 nuts

Two M6 1.0 nuts were welded on. The second nut was mounted flange side out to provide a mating surface for the rubber O-ring on the adapter. It's not pretty but it works.