DIY: RX-8 Engine Removal How-to-with Pics

#101

kevin@rotaryresurrection

Thread Starter

iTrader: (3)

Join Date: Feb 2005

Location: east of Knoxville, TN

Posts: 1,415

Likes: 0

Received 57 Likes

on

35 Posts

Also, you are using the PCM that was originally in your car, correct? The PCM and the key must always match. If you try to use a PCM from another car with your key it will not allow the engine to start.

The following users liked this post:

ASH8 (10-24-2019)

#102

Got the car running just now..

had to get it running with giving some gas and keep it alive with giving it gas

runs badly, but sounds like its getting smoother as i run it..

have runned it twice now..

here's a video from the second start..

before getting it started i swapped my old spark plugs in so i don't mess up the new ones..

the new ones were already really oily and glogged up just after like 10-15 start attempts

#103

kevin@rotaryresurrection

Thread Starter

iTrader: (3)

Join Date: Feb 2005

Location: east of Knoxville, TN

Posts: 1,415

Likes: 0

Received 57 Likes

on

35 Posts

Either you have one primary injector not firing, one or more coils not firing, or one or more plugs not sparking/fouled. It is running on one rotor in that first video.

#104

will check those connectors today and see if they are correctrly in place

coils / plugs should be working , they aint that old... but you never know

#105

got the intake out, the fuel line for the fuel rail was loose and top of the engine block was flooding with gasoline...

maybe the problem was there..

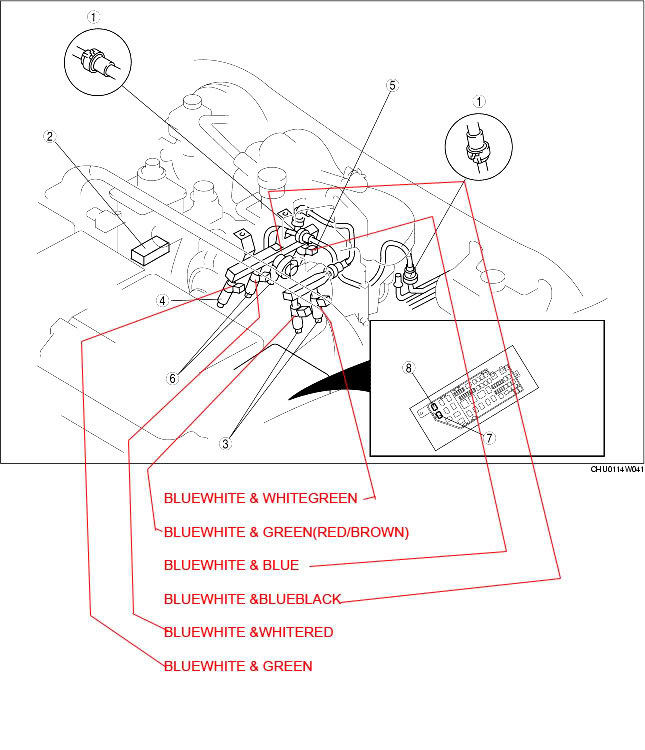

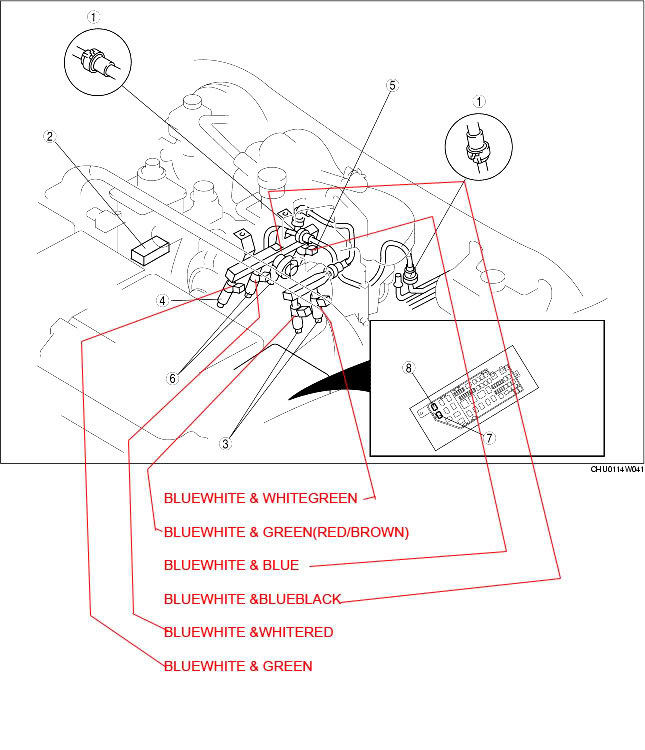

but heres a awesome picture of how my injectors are connected (by wire colors)

maybe the problem was there..

but heres a awesome picture of how my injectors are connected (by wire colors)

#108

i was so professional minded that "sure i will remember this" :D

and i did swap the harness from a engine to a another when the engine were sitting side by side on the floor

but still :D

and i did swap the harness from a engine to a another when the engine were sitting side by side on the floor

but still :D

#109

any idea why my clutch resist to work proberly now?

pedal sit kinda soft and numb.

got it in gear once and jumped the car forwards couple inch.. after that like a invisible wall blocking the gears?

pedal sit kinda soft and numb.

got it in gear once and jumped the car forwards couple inch.. after that like a invisible wall blocking the gears?

#110

kevin@rotaryresurrection

Thread Starter

iTrader: (3)

Join Date: Feb 2005

Location: east of Knoxville, TN

Posts: 1,415

Likes: 0

Received 57 Likes

on

35 Posts

Input shaft dirty, has debris, or is not lubricated enough for the disc to slide freely on the splines. Or pilot bearing in e-shaft bad or damaged during install.

Either necessitates trans removal to repair.

First try adjusting the clutch pedal in such a way that it loads the master cyl sooner/more. If that doesn't take care of it then it is one of the other two.

Either necessitates trans removal to repair.

First try adjusting the clutch pedal in such a way that it loads the master cyl sooner/more. If that doesn't take care of it then it is one of the other two.

#112

Gulf Coast Rotaries

iTrader: (1)

This was so helpfully , lot of my friends said your crazy man is a newer car and a rotary ,lol ,. One thing they didn't know is that I had this guy to guide me lol RR you have been so helpfully with this write up worked perfect like if I was a pro on rx8 lol. Thanks

#113

I can not thank you enough for this how to post! We were going to part out/crush the car we figured it wasn't worth repairing (had a hot no start issue due to low compression). Than I saw this post and went to get some tools...

Just removed the engine and getting ready to tear it down. Also in neutral this car had a bearing noise I am going to look into that too.

When Rotary engine has normal compression are you supposed to be able to spin it by hand on the flywheel?

Just removed the engine and getting ready to tear it down. Also in neutral this car had a bearing noise I am going to look into that too.

When Rotary engine has normal compression are you supposed to be able to spin it by hand on the flywheel?

#114

kevin@rotaryresurrection

Thread Starter

iTrader: (3)

Join Date: Feb 2005

Location: east of Knoxville, TN

Posts: 1,415

Likes: 0

Received 57 Likes

on

35 Posts

Also in neutral this car had a bearing noise I am going to look into that too.

When Rotary engine has normal compression are you supposed to be able to spin it by hand on the flywheel?

#115

It seemed like it was going to cost more to repair the car than what it would be worth once it is repaired so we tought "oh well we'll part it out the good and recycle the rest". Dealer quoted us $6000 and that is what they sell for around here with 100K+

I have parted out many motorcycles in the past most of the time it works out quite well financialy but I have never done a car and it looks like it would take a lot of space which we don't have.

Instead I found this post - thank you much. Looks like it might get repaired after all!

How much torque is on that flywheel nut?

I have parted out many motorcycles in the past most of the time it works out quite well financialy but I have never done a car and it looks like it would take a lot of space which we don't have.

Instead I found this post - thank you much. Looks like it might get repaired after all!

How much torque is on that flywheel nut?

#117

realy helpful

thanks a lot ,,, yost finish to remove my engine and now i am ready for the teredown, do you know were i can find the parts for a rasonable price? the braket for the engine stand and stret porting template,

#122