Lean burn with negative split timing

#154

My main tool is Ida Pro.

I'm using the tools and techniques of the Subaru and Mitsubishi open-source tuning communities and trying to apply them to the RX-8 ECU.

I've been working on reverse-engineering the USDM 6 speed rom code for months, but I've only recently started to become competent at understanding SH2E assembler. It is an unusual hobby.

I'm using the tools and techniques of the Subaru and Mitsubishi open-source tuning communities and trying to apply them to the RX-8 ECU.

I've been working on reverse-engineering the USDM 6 speed rom code for months, but I've only recently started to become competent at understanding SH2E assembler. It is an unusual hobby.

#156

Release the twins.

#157

Registered

iTrader: (3)

I hate to bring this up because I know it is stirring the pot, but the reason for negative split timing is to run the engine timing super advanced. This both catches the richer fuel and gives the ultra lean mixture more burn time. It's not enough to lean out the mixture, or run advanced timing, both must be done in a controlled way. The potential benefits are huge, but in order to get there you need to go through a very dangerous region. Running lean without advancing is going to raise EGT, and eventually lower fuel economy. Advancing timing alone is going to drop EGT, and raise ECT and raise fuel economy until it starts dropping again. Both need to happen at the same time in controlled amounts or you will be running closer to detonation. Also you need to get AFRs high enough to start lowering combustion temps or you are running closer to det.

MM's suggestion to raise AFRs in cruise for better fuel economy is almost the same as advancing timing, except the extra fuel also cools the engine internally.

My point is that in order to do this you have to go through very bad places with the engine, and you have to be very careful when you do. I recommend using water free coolant because it does provide a little extra safety margin.

MM's suggestion to raise AFRs in cruise for better fuel economy is almost the same as advancing timing, except the extra fuel also cools the engine internally.

My point is that in order to do this you have to go through very bad places with the engine, and you have to be very careful when you do. I recommend using water free coolant because it does provide a little extra safety margin.

#158

The Stink w.o The Sause

iTrader: (5)

ECT?

I definitely agree with you tho ... you need to go lean and quick ... the question is how much timing you wanna run? The factory split maxes out at around 15 degrees ... can be a couple degrees more in unique situations during changing Rpms.

How fast will the flame front travel in a lean mixture?

I definitely agree with you tho ... you need to go lean and quick ... the question is how much timing you wanna run? The factory split maxes out at around 15 degrees ... can be a couple degrees more in unique situations during changing Rpms.

How fast will the flame front travel in a lean mixture?

#159

Registered

ECT?

I definitely agree with you tho ... you need to go lean and quick ... the question is how much timing you wanna run? The factory split maxes out at around 15 degrees ... can be a couple degrees more in unique situations during changing Rpms.

How fast will the flame front travel in a lean mixture?

I definitely agree with you tho ... you need to go lean and quick ... the question is how much timing you wanna run? The factory split maxes out at around 15 degrees ... can be a couple degrees more in unique situations during changing Rpms.

How fast will the flame front travel in a lean mixture?

Compression is also a factor, I have run AFrs of 18.5-21 to 1 steady, with no negative split, but I have lower compression. At that far lean, there is a lot less engine heat than say 14-15 to 1, there is very little energy keeping the car going, my injector duty at 80 was down to what I expected at 30 to 40.

Can I go farther lean with negative split? (EFI dude file)

Last edited by Rote8; 03-19-2012 at 08:24 AM.

#160

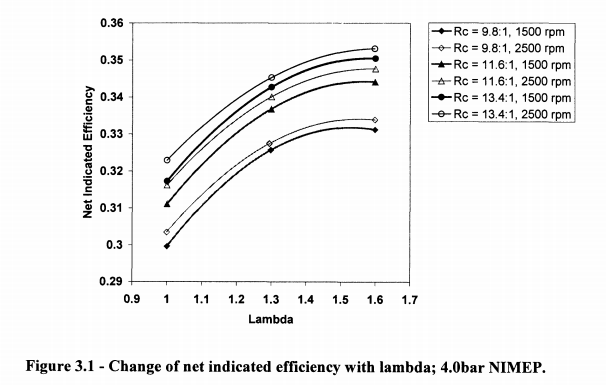

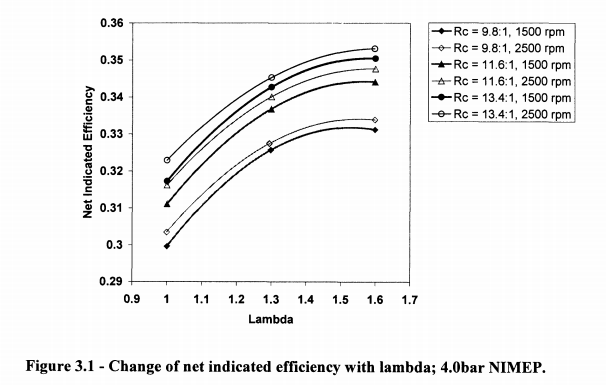

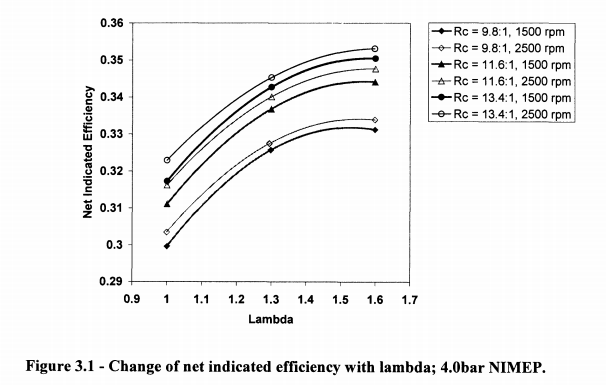

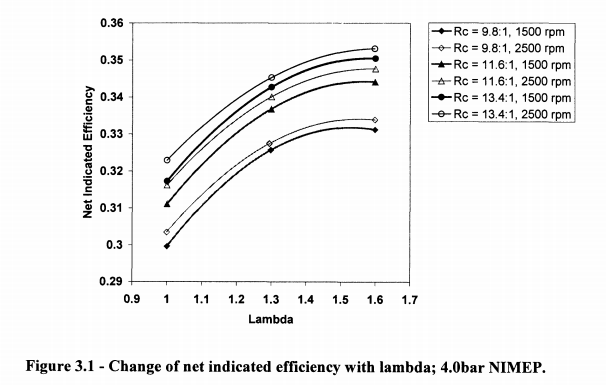

Generally, efficiency improves ~2.5% per point of increased compression ratio, until it peaks at ~14:1. This is due to increased heat transfer.

Source

Of course, that assumes ignition timing is not knock-limited. I think those measurements were taken with research fuel or toluene.

Some in the rotary aviation world have suggested that combustion chamber temperatures are not as problematic as they are for piston engines, and I assume we're talking about ECT as a proxy for that. Cast-iron rotors, and absent exhaust valves mitigate some failure points.

Source

Of course, that assumes ignition timing is not knock-limited. I think those measurements were taken with research fuel or toluene.

Some in the rotary aviation world have suggested that combustion chamber temperatures are not as problematic as they are for piston engines, and I assume we're talking about ECT as a proxy for that. Cast-iron rotors, and absent exhaust valves mitigate some failure points.

#161

subscribing,

so oltmann what does happen when the rear o2 is just removed and the sensor is unplugged?

as far as it relating to closed loop table B, makes more sense then other guesses...

so oltmann what does happen when the rear o2 is just removed and the sensor is unplugged?

as far as it relating to closed loop table B, makes more sense then other guesses...

#162

Registered

iTrader: (3)

How much timing is a great question. I've found the naca water injection report to be a treasure trove of information.

http://naca.central.cranfield.ac.uk/...a-wr-e-264.pdf

on page 11 it has ignition timing vs Fuel/air ratio which shows how much timing has to be advanced. The differences in engines are huge, but use it as a ballpark for how fast the fuel burns.

EGT is a good indication for when you are too retarded. Ideally you want to shift the burning of the fuel to happen closer to TDC and further away from the exhaust. The problem is that the actual burn speed is effected by pressure, so as you start getting close to the optimum point smaller and smaller advances push the flames closer and closer to TDC. Hopefully this will show itself in coolant temperature before that point has been crossed. Also if EGTs start dropping rapidly you have gone too far.

Knock limited is a potential problem. I'm running water free so I'm not as worried, but be aware that when you do draw steam bubbles in your coolant channels it is a snowballing reaction to boilover/overheat/detonation. The steam acts as an insulator making the coolant channel temperatures increase to keep transferring the same amount of heat to the remaining water in contact until you end up with a dry cooling channel and a blown engine. So if you decide to go down this rabbit hole, know that a blown engine is potentially minutes away with a bad tune.

Add to that the high power density and internal surface area of a rotary and you have a potential for bad consequences very fast.

Feel free to correct anything I've gotten wrong, I'm pretty much learning by the seat of my pants since nobody else does this sort of thing with rotarys.

While I'm waiting for part's and time, I'm gonna try doing a baseline map which raises the Fuel VE while decreasing the AFR to maintain stock fueling in open loop. That should be a good place to start.

http://naca.central.cranfield.ac.uk/...a-wr-e-264.pdf

on page 11 it has ignition timing vs Fuel/air ratio which shows how much timing has to be advanced. The differences in engines are huge, but use it as a ballpark for how fast the fuel burns.

EGT is a good indication for when you are too retarded. Ideally you want to shift the burning of the fuel to happen closer to TDC and further away from the exhaust. The problem is that the actual burn speed is effected by pressure, so as you start getting close to the optimum point smaller and smaller advances push the flames closer and closer to TDC. Hopefully this will show itself in coolant temperature before that point has been crossed. Also if EGTs start dropping rapidly you have gone too far.

Knock limited is a potential problem. I'm running water free so I'm not as worried, but be aware that when you do draw steam bubbles in your coolant channels it is a snowballing reaction to boilover/overheat/detonation. The steam acts as an insulator making the coolant channel temperatures increase to keep transferring the same amount of heat to the remaining water in contact until you end up with a dry cooling channel and a blown engine. So if you decide to go down this rabbit hole, know that a blown engine is potentially minutes away with a bad tune.

Add to that the high power density and internal surface area of a rotary and you have a potential for bad consequences very fast.

Feel free to correct anything I've gotten wrong, I'm pretty much learning by the seat of my pants since nobody else does this sort of thing with rotarys.

While I'm waiting for part's and time, I'm gonna try doing a baseline map which raises the Fuel VE while decreasing the AFR to maintain stock fueling in open loop. That should be a good place to start.

#163

You may find this one interesting, they measure fuel concentration at the plug in a Renesis for rich, stoich, and lean:

In-Situ Fuel Concentration Measurement Using an IR Spark Plug Sensor by Laser Infrared Absorption Method - Application to a Rotary Engine

It is also possible to measure this by way of ionization current across the plug gap. I've wondered if this could be done DIY, but never investigated.

so oltmann what does happen when the rear o2 is just removed and the sensor is unplugged?

You will lose the benefits of the sensor, mainly correcting errors in the wideband sensor due to aging. So, you might consider replacing it more frequently. IIRC, you have a second wideband, so as long as you check that occasionally you should be able to see if the front sensor is going bad. Of course, it needs a free-air calibration fairly often as well.

I have seen some Subaru guys suggest that they have seen benefits from retaining the rear O2 even without a cat. Those ecus draw from the same codebase as the RX8, and the sensors are (at least electrically) identical, might be worth thinking about.

#164

Registered

iTrader: (3)

Rear O2 is now unplugged and commanded AFRs are now very predictable!! No phantom trim. Spark plug ionization is a long term WIP, I'd just be happy to have coils that could support it wired into my car at this moment. Ion sensing, is equally as useful for timing which is my goal.

Tried running a special map to get to stoich with a richer set AFR and a higher VE. Turns out I took VE to the wrong direction, but I figured it out. I didn't like the hicups in the transitions though. I'm gonna try a slower transition and just change VE to get AFR where I want. Should be able to just tweak the area of the map I cruise at without changing much else so long as I taper the transitions.

Tried running a special map to get to stoich with a richer set AFR and a higher VE. Turns out I took VE to the wrong direction, but I figured it out. I didn't like the hicups in the transitions though. I'm gonna try a slower transition and just change VE to get AFR where I want. Should be able to just tweak the area of the map I cruise at without changing much else so long as I taper the transitions.

#165

Registered

iTrader: (1)

Generally, efficiency improves ~2.5% per point of increased compression ratio, until it peaks at ~14:1. This is due to increased heat transfer.

Source

Of course, that assumes ignition timing is not knock-limited. I think those measurements were taken with research fuel or toluene.

Some in the rotary aviation world have suggested that combustion chamber temperatures are not as problematic as they are for piston engines, and I assume we're talking about ECT as a proxy for that. Cast-iron rotors, and absent exhaust valves mitigate some failure points.

Source

Of course, that assumes ignition timing is not knock-limited. I think those measurements were taken with research fuel or toluene.

Some in the rotary aviation world have suggested that combustion chamber temperatures are not as problematic as they are for piston engines, and I assume we're talking about ECT as a proxy for that. Cast-iron rotors, and absent exhaust valves mitigate some failure points.

That being said, based on what I see Mazda doing with Sky-Activ, I am increasingly interested in figuring out how a 14:1 Renesis could be put together & tuned.

#167

I decided to try this out again, and it is far easier to tune than I had realized in my previous attempts. The closed loop a/f targets tables are really the base fueling targets. They are always used to calculate fueling, past 6000 rpm the rightmost column is used, and exiting closed loop just means turning off feedback control and turning on high load enrichment compensation (aka open loop.)

The lean and rich limits (1.05 and 0.85) apply to the commanded equivalence ratio, which is used to calculate fuel trims when in closed loop, but the actual value pulled from this table is used to calculate fueling, not the commanded eq.

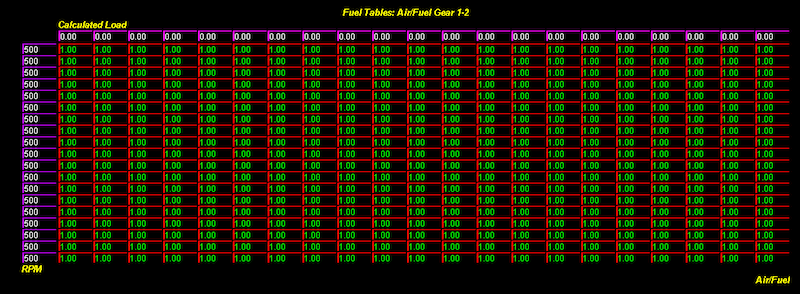

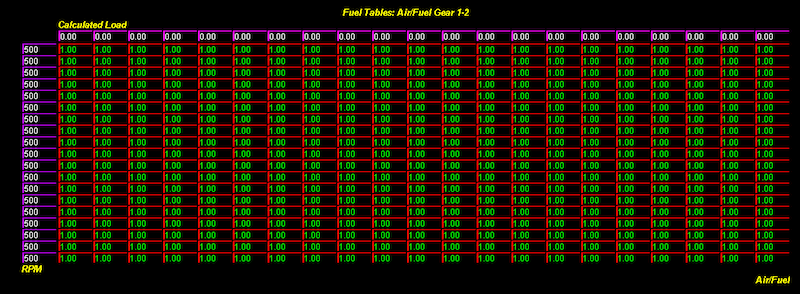

Based on that idea, I set closed loop exit rpm to 2000, zeroed (or oned) all other fuel tables, and set closed loop targets A like so:

Also added about 10 deg advance in the lean areas.

Well, it was surprisingly driveable. Not perfect, but it convinced me as a proof of concept. No clue about fuel economy, but whatever the ideal AFR may be, the lean misfire limit of the Renesis is quit high.

My MAF and injector scalars are stock, I also recommend leaving the VE table stock, or nearly so, as I still don't really understand what it does (and at least one of my working theories is a bit scary.)

The lean and rich limits (1.05 and 0.85) apply to the commanded equivalence ratio, which is used to calculate fuel trims when in closed loop, but the actual value pulled from this table is used to calculate fueling, not the commanded eq.

Based on that idea, I set closed loop exit rpm to 2000, zeroed (or oned) all other fuel tables, and set closed loop targets A like so:

Also added about 10 deg advance in the lean areas.

Well, it was surprisingly driveable. Not perfect, but it convinced me as a proof of concept. No clue about fuel economy, but whatever the ideal AFR may be, the lean misfire limit of the Renesis is quit high.

My MAF and injector scalars are stock, I also recommend leaving the VE table stock, or nearly so, as I still don't really understand what it does (and at least one of my working theories is a bit scary.)

#172

Registered

iTrader: (3)

Wow that's much leaner than I've tried.

Team, the closed loop A/F target A map is really closer to an actual fuel VE table as it is used for all fueling. oltmann explained it to me very concisely and it works like a champ.

I'm really timid on how far to advance timing. I'm willing to try crazy things, but I don't want to destroy my engine either. Would post my maps, but they are not that exciting yet.

Team, the closed loop A/F target A map is really closer to an actual fuel VE table as it is used for all fueling. oltmann explained it to me very concisely and it works like a champ.

I'm really timid on how far to advance timing. I'm willing to try crazy things, but I don't want to destroy my engine either. Would post my maps, but they are not that exciting yet.

#173

There is no real rule about how to bin the tables, they need not be equal width, and they all have their own set of axes.

I picked those bins because they described the fuel map I wanted, and they looked nice to me.

I set the open loop maps up so that the table lookups take as few cycles as possible. I feel that the main fuel table (so called closed loop targets) is more than adequate, and I like having all the data in one place. If I had to optimize for catalyst temps, I might feel differently.

I picked those bins because they described the fuel map I wanted, and they looked nice to me.

I set the open loop maps up so that the table lookups take as few cycles as possible. I feel that the main fuel table (so called closed loop targets) is more than adequate, and I like having all the data in one place. If I had to optimize for catalyst temps, I might feel differently.

#174

Registered

iTrader: (3)

Been tuning and increasing timing. Running a 20deg neg split with max of 58deg. Gotten to about +12deg and taking it up in increments each day. My engine seems to love timing and love coolant temp with regard to fuel economy and lowering EGTs. No signs of knock yet. Figure at somewhere around 45deg BTDC timing will gain a lot more bite so I'm taking it slow.

#175

Registered

iTrader: (3)

Gotten to about +14 deg leading above stock in cruise cells. Currently have trailing stop increasing at +60deg, but as split goes less then 10 may keep pushing it. EGTs are coming down and fuel economy is going up. Started to think my excessive timing was indicative of low compression, but confirmed my idle vac is >20. So I have very odd tuning issues. Also made a spreadsheet to calculate timing by deviation in burn speed. Should allow better inference of the rest of the map. I took the stock timing +45 then multiplied it by a burn speed multiplier and subtracted 45. Should be pretty close. Keep adding timing everyday and logging results. Seems very positive.

Also, trailing timing seems to have very little impact on effective timing. (Not to say that negative split is meaningless, not at all!) The point is that the trailing spark plug goes through such a little hole that it takes a while for the fire it lights to truly start, so running neg split or positive split doesn't seem to shift effective timing by that much. The most important thing seems to be maintaining a split, as such you are starting the fire in the field at two places at different times so that running total timing too far advance or too far retarded doesn't matter as much. If the first one fires too soon during compression it burns more of the fuel before the other lights it, so effective timing is retarded from actual value. If it starts too late it leaves more fuel for the other plug so effective timing is advanced. If you had dead on timing you could fire them both at the same time, but any little change would throw you into a bad place. I was daydreaming and that kinda came to me. If someone else has contradicting knowledge/insight please inform us.

Also, trailing timing seems to have very little impact on effective timing. (Not to say that negative split is meaningless, not at all!) The point is that the trailing spark plug goes through such a little hole that it takes a while for the fire it lights to truly start, so running neg split or positive split doesn't seem to shift effective timing by that much. The most important thing seems to be maintaining a split, as such you are starting the fire in the field at two places at different times so that running total timing too far advance or too far retarded doesn't matter as much. If the first one fires too soon during compression it burns more of the fuel before the other lights it, so effective timing is retarded from actual value. If it starts too late it leaves more fuel for the other plug so effective timing is advanced. If you had dead on timing you could fire them both at the same time, but any little change would throw you into a bad place. I was daydreaming and that kinda came to me. If someone else has contradicting knowledge/insight please inform us.

Last edited by Harlan; 04-04-2012 at 08:20 PM. Reason: Added stuff.