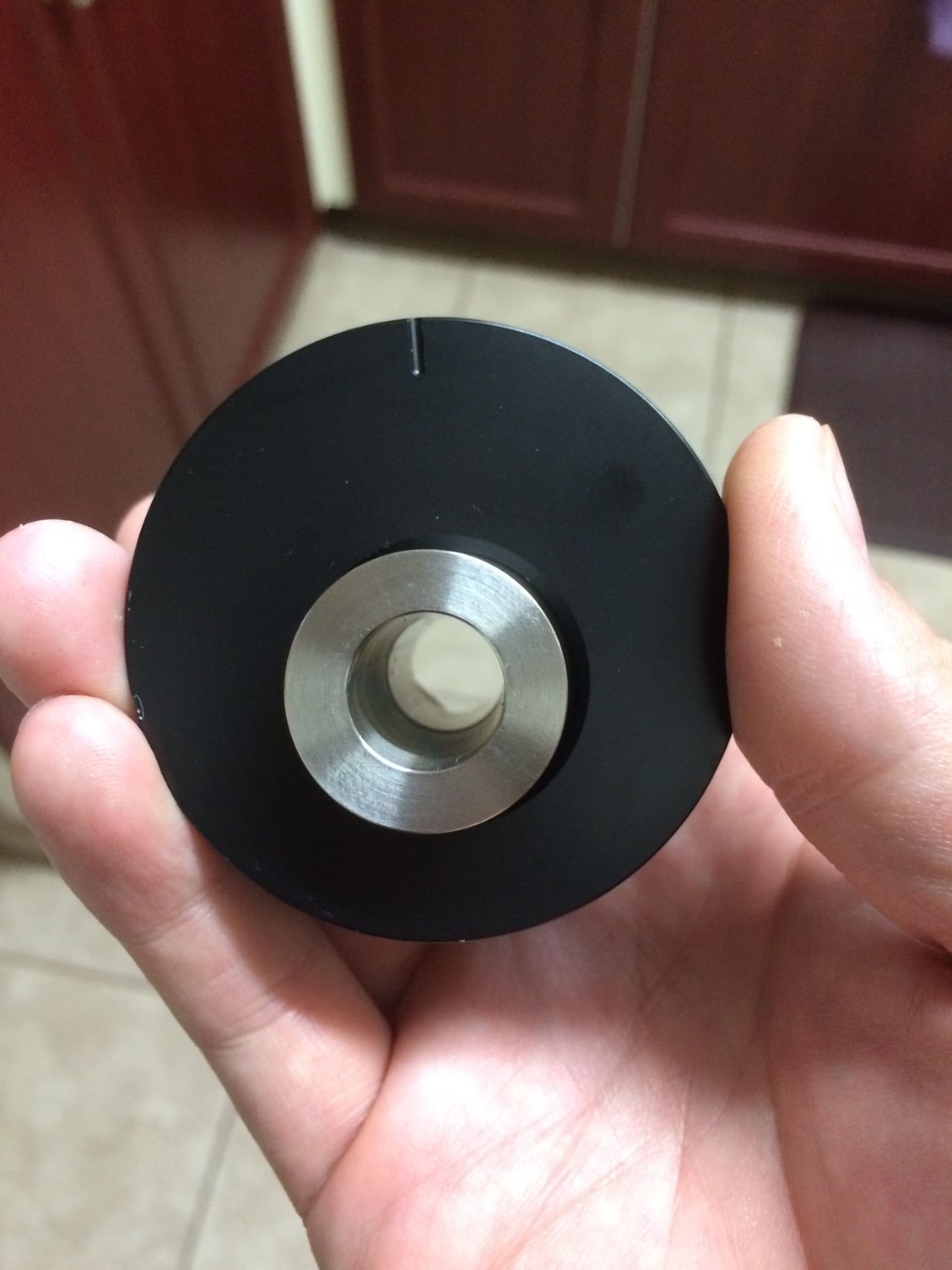

Delrin camber LCA busing install

#10

Are the bushing completely rubber or they they have a metal outer sleeve.

My shop wants only 200 bux for labor to do it.........so tempting.

My shop wants only 200 bux for labor to do it.........so tempting.

Last edited by thewatcher101; 03-03-2015 at 05:43 PM.

#12

Modulated Moderator

iTrader: (3)

carefully remove the rubber bushing and sleeve from LCA

press the new one in...you don't want it to be loose ( so no lube )...or it will rotate and screw up your alignment. I had to TIG weld the big side to the control arm as it would turn when I banged off the curbs at the track. For more "normal" usage it likely isn't an issue

)...or it will rotate and screw up your alignment. I had to TIG weld the big side to the control arm as it would turn when I banged off the curbs at the track. For more "normal" usage it likely isn't an issue

Then put in the bearing and the retaining side with the screws and you should be good

press the new one in...you don't want it to be loose ( so no lube

)...or it will rotate and screw up your alignment. I had to TIG weld the big side to the control arm as it would turn when I banged off the curbs at the track. For more "normal" usage it likely isn't an issue

)...or it will rotate and screw up your alignment. I had to TIG weld the big side to the control arm as it would turn when I banged off the curbs at the track. For more "normal" usage it likely isn't an issueThen put in the bearing and the retaining side with the screws and you should be good

#14

Modulated Moderator

iTrader: (3)

You shouldn't torch it......when I did mine I had already cut the front part of the bushing off as it had seized on the bolt. I pressed out the center part and then sliced the outer metal sleeve carefully part way through and pressed it out. As I remember it took an hour a side...in a shop with air tools, an air chisel and die grinders...a vise and a press. Not sure doing it at home would be a fun job

It isn't simple...and you need to be patient. If you screw it up it get expensive really quick

It isn't simple...and you need to be patient. If you screw it up it get expensive really quick

#15

The shop it is then, thank you for that advice. I think I will only do one side since only my driver side not getting the angle it needs. My car is track too and since this part doesn't hold onto it's alignment as well as stock bushing. I would like to keep it as stock as possible. For the price he is asking, it would be totally worth it. It does not sound fun.

Wouldn't welding the bushing in place, remove any ability to adjust it?

Wouldn't welding the bushing in place, remove any ability to adjust it?

#21

No respecter of malarkey

iTrader: (25)

The part where you snuck in while I was replying to the OP ...

Tack welding it makes perfect sense, butnot researching, or acquiring an understanding, or not reading the instructions for modifications before you go there, not so much

.

Tack welding it makes perfect sense, butnot researching, or acquiring an understanding, or not reading the instructions for modifications before you go there, not so much

.

Last edited by TeamRX8; 03-19-2015 at 11:36 PM.

Thread

Thread Starter

Forum

Replies

Last Post

TotalAutoPerformance

Vendor Classifieds

12

10-17-2018 09:00 AM

jasonrxeight

RX-8's For Sale/Wanted

2

09-30-2015 01:53 PM

Evan Gray

Series I Trouble Shooting

0

09-26-2015 12:30 PM